7 étonnants fabricants de prototypes 3d et compétences de prototypes rapides 3d

Prototypage 3D rapide: qu'est-ce que c'est, comment ça marche et à quoi ça sert?

Qu'est-ce qu'un fabricant de prototype 3D et un prototype rapide 3D?

À l'heure actuelle, nous entendons souvent parler de fabricant de prototype 3D et de prototype rapide 3D . Nombreux sont ceux qui le font par le commerce. De même, beaucoup d'autres souhaiteraient aborder cette technique pour améliorer les processus de production de leur entreprise.

But they are still hesitating. The main reason is perhaps, you are not perfectly aware of the topic.

Rapid 3D prototyping: it is a very common name. You might have heard if you are approaching the world of impression 3D for work. It will have probably happened to you at least once to find yourself in front of this name.

So,

- Qu'est-ce 3d prototype manufacturer & 3d rapid prototype in 3D printing?

- Why we need it?

- What are the practical advantages?

Behind this name, it might seem very technical and difficult. But it hides a very useful tool.

How to convert files with 3D rapid prototyping from your pc?

The English definition of prototype strongly captures its essence: ‘ an early representation of an idea solution ‘. So it is a realistic preview that concretizes an idea. Literally, making prototypage rapide means making prototypes quickly. But what are they and how are they produced by the PC?

Le 3d prototype manufacturer & 3d rapid prototype are the initial elements of a production series. Who produces a good has always made a prototype before putting it in real production:

- investing time

- money and

- resources and

- the market

Think of the paper clothes models, the scale furniture models etc.

They are obtained through three-dimensional CAD modelers. It comes from the conversion of 3D files into STL.

Until a few years ago, the production of a prototype with traditional methods could take whole days. With 3D prototyping, the manufacturing process ends in a few hours with a big cut in costs.

Test your idea: make the 3D prototype

The British say “fail early, succeed sooner “. The winning mentality is to test one’s ideas with the aim of always improving, without fear of failing.

You have a new idea and want to test it? You can do it quickly and economically with the 3D printing prototype. With this system 3d prototype manufacturer & 3d rapid prototype can make it a reality. One can draft and correct it before launching.

To better understand the potential of rapid prototyping, let’s think about the single design phase. If in the past to make an object, following things were important:

- injection molds and techniques

- accurate thickness and size

- minimum deformation

This technology allows 3d prototype manufacturer & 3d rapid prototype to design in 3D freely. Hence, it can happen in a short time. Moreover, it saves a huge cost too. But above all it makes useless real models of the object faithful to the original.

It is also possible to separately manufacture the components. Therefore, we can assemble it later. There is no need to make single piece separately.

In which sectors is 3D prototyping applied?

The potential of 3D prototyping can therefore be hypothesized in various sectors. However, the most promising scenarios concern the areas:

Aerospace: to solve possible design problems quickly and economically;

Automotive: in this competitive sector, being a pioneer in the market can make a difference. From trucks to racing cars through normal cars, prototyping with 3D printing solutions allows you to create prototypes. Furthermore, it performs tests quickly and effectively;

Healthcare: the prototyping of medical devices with 3D printing allows you to test the components. It is possible at the same time they are produced. From the additive manufacturing of functional parts to the creation of models for tests, etc.

How 3D prototyping works: comparing technologies

If you find yourself reading this page, it is because, in all likelihood, you are curious to find out more. So let’s see better how 3d prototype manufacturer & 3d rapid prototype works.

The first major distinction that we can now make is between additive, subtraction and fusion. All three basically allow you to make an object in full scale.

Generally, the most common is the first one. Through this 3D printing, obtains the prototype. Within the additive manufacturing different techniques are distinguished. These are:

- FDM

- SLS

- SLA

- MJP

- CJP and SCP.

Let’s analyze the differences more precisely.

3d prototype manufacturer & 3d rapid prototype Additive prototyping techniques

More specifically, they fall into this category:

Fused deposition modeling: also suitable for very light materials such as ABS and PLA. Fused Deposition Modeling was born in the late 80s.

Stereo lithography: SLA is the first rapid prototyping technique. It is based on the polymerization of a liquid resin using lasers. This system allows the production of even rather complex and delicate pieces.

Selective laser sintering: Selective Laser Sintering uses a laser that melts different powders. Later, it spread them on layers. In this way a more precise and resistant prototype is obtained. But the finishing tends to be less precise.

Poly Jet: Technology applicable to very different materials. It therefore allows fabricant de prototype 3D et de prototype rapide 3D to obtain prototypes of particular shapes.

Poly Jet: Technology applicable to very different materials. It therefore allows fabricant de prototype 3D et de prototype rapide 3D to obtain prototypes of particular shapes.

The limit is that prototypes tend to be less resistant. Thanks to its high precision and speed of realization.

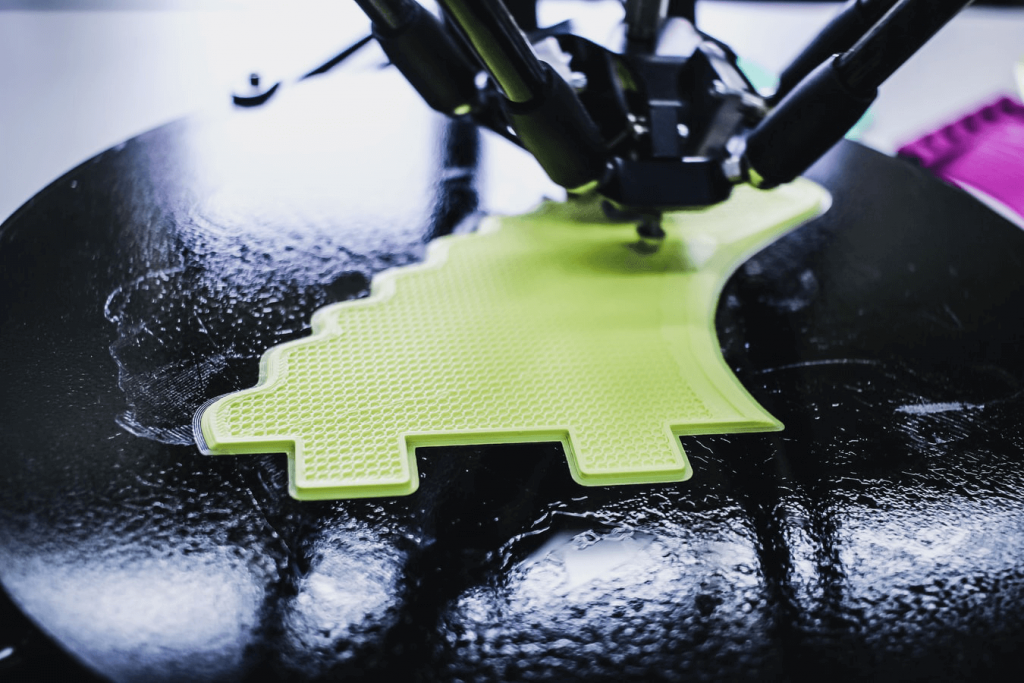

Impression 3D: technologie préférée des fabricants experts en fabrication numérique. Il est très rapide à imprimer et très facile à appliquer dans la création de prototypes.

Implémentée en 1993, la technique d'impression 3D est basée sur des têtes d'impression jet d'encre. Il libère un composé liquide à base de colle sur un matériau composé de:

- Amidon

- plâtre ou

- Poudre de céramique.

Les objets ainsi obtenus sont caractérisés par des couleurs vives. Mais, d'un autre côté, ils semblent moins résistants et rugueux.

Impression Multi Jet: Elle est apparue en 2006. Cette technique est basée de manière centrale sur la fusion et le dépôt de couches. Par la suite, c'est pour les matériaux résistants aux hautes températures. Le résultat est une finition très détaillée.

Techniques de prototypage de soustraction et de fusion

Secondly we find the subtractive production which, instead, follows the opposite path. fabricant de prototype 3D et de prototype rapide 3D start from a block of unique material. He gradually removes the superfluous until he obtains the finished product.

Also in this case the technologies can be different.

- Milling

- turning and

- drilling are the best known

Lastly, the fusion creates prototypes starting from a model. After 3D printing, a silicone rubber mold is obtained. It is filled with the final material. This too can be a useful technique. However, since it requires several steps, the merger is more suitable for large lots.

Better projects with 3d prototype manufacturer & 3d rapid prototype impression 3D

No matter what you design, you almost never get the best product right away

Prototyping is essential to eliminate design errors. That can only emerge after production has started. A realistic 3d prototype manufacturer & 3d rapid prototype represents a very effective tool for marketing actions.

It also improves understanding of the project within the team. In addition, it reduces the risk of error.

Rapid prototyping with 3D printer

More revisions, in less time, with reduced costs

Identifying and solving problems early in the design cycle is essential to prevent waste and rework. Rapid prototyping with 3D printing allows industrial designers and engineers more overhauls in less time. It maintains in-depth tests, while reducing time to market.

Physical models convey ideas to:

- collaborators

- customers and

- distributors immediately and clearly

Les 3d prototype manufacturer & 3d rapid prototype facilitates the communication of the concept. It allows to obtain detailed feedback. It is essential for the success of the product.

Simplify the design process with 3d prototype manufacturer & 3d rapid prototype impression 3D

All projects are born from an idea. Develop it without wasting time.

The design process is by its nature an adventure into the unknown. It will always result in frustrating questions.

Prototyping is essential to eliminate design errors. It can only emerge after production has started. A realistic prototype represents a very effective tool for marketing actions.

It also improves understanding of the project within the team. Moreover, it reduces the risk of error.

- Functional tests

- aesthetic and

- dimensional checks

These are the best way to evaluate what works and what doesn’t. Rapid prototyping with 3D printing offers the flexibility to make this process simple and convenient.

Design of machines with metal 3D printing: applications and advantages

In the design of machines we can identify some key phases:

- development

- industrialization

- manufacture and

- maintenance

It is critical to ensure that machines operate efficiently. It produces consistent results. Subsequently, it has easy repairing module. In this context, 3d prototype manufacturer & 3d rapid prototype brings numerous advantages to designers and builders.

Machine design: 3d prototype manufacturer & 3d rapid prototype critical factors

- For simplicity

- speed and

- above all

- Cost

Machine designers strive to use as many standard components as possible. However, some parts need to be custom made. And this implies an effort to reduce manufacturing costs and times.

Custom parts have typically CNC machining capacity due to small volume. A process that can be expensive and time consuming depends on the complexity of the part.

In addition, 3d prototype manufacturer & 3d rapid prototype that design and build machines often face problems. They are related to equipment. That is already in operation.

Some parts that make up the machine wear out or break. Companies must be able to quickly produce spare parts to restore the functionality of the machine. It keeps parts costs low and avoiding storage costs as much as possible.

How 3D printing rapid prototype simplifies the design of machines and their construction?

The additive manufacturing greatly simplifies the process of creating custom parts. It is not based on equipment or fasteners. 3D printing often allows users to print parts faster and at lower costs than traditional processing.

Metal 3D printing technology also opens doors to parts with greater geometric complexity. These complex parts may be more suitable for the application. They induce greater efficiency. But they are generally very difficult.

The ability to build even complex parts more easily allows fabricant de prototype 3D et de prototype rapide 3D to consolidate assemblies. It combines multiple parts into a smaller number of multifunctional assemblies.

It will result in simplified production and increased efficiency. Designing in 3D for Additive Manufacturing allows you to take advantage offered by additive technology.

Le 3d prototype manufacturer also helps to simplify the production of spare parts. It enables companies to print exactly the part they need. When and where they need it? It significantly reduces both downtime that inventory costs.

3d prototype manufacturer & 3d rapid prototype Machine design

The contexts in which the use of 3D printing in machine design offers significant advantages are manifold.

Production methods such as:

- Casting

- forging and

- injection molding of metals

They are ideal for mass production. They are not very convenient for prototype construction. It is due to the high costs and long delivery times. 3D printed parts can have the same quality as those obtained with the mass production methods.

But the use of tools is not necessary, with a significant saving of time and money. Since 3D printing eliminates the need for tools, the part can be easily printed.

fabricant de prototype 3D et de prototype rapide 3D offer a growing autonomy of work. Prints can also be performed during the night.

Using the 3D metal printing of Desktop Metal Studio System, this part can be quickly prototyped. Whenever you need without performing the merger, it greatly reduces the cost of the part.

Moreover, it impact the manufacturing lead time.

At present, fabricant de prototype 3D et de prototype rapide 3D embrace the entire world production system. It involves:

- Craftsmen

- Architects

- Planners

- Designers

- engineers and industrialists

But, I can’t tell you that in a few years there will be a 3D prototype on each desk. Because it would mean making fun of you.