Looking for a reliable, quick-turn supplier of Plastic Injection Molding? With hundreds of CNC machines, our unmatched in-house capacity ensures your parts are shipped on-time, every single time. At Katio, our ISO 9001 certified CNC machining facilities are designed for both rapid prototyping and low-volume production of end-use components.

Our plastic injection molding process produces custom prototypes and end-use production parts in 15 days or less. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock more than 100 different thermoplastic resins.

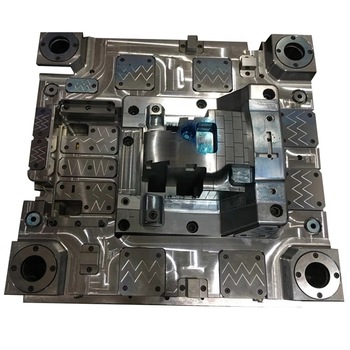

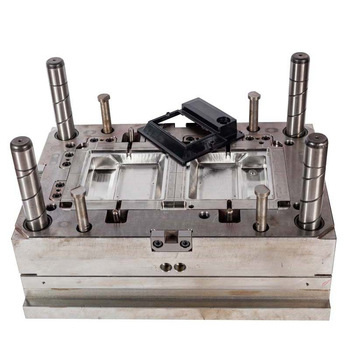

How Does Plastic Injection Molding Work?

The thermoplastic injection molding process at kaito Mould is a standard process involving an aluminum mold with no heating or cooling lines running through it, which means cycle times are a bit longer. It allows our molders to monitor fill pressure, cosmetic concerns, and the basic quality of the parts.

Resin pellets are loaded into a barrel where they will eventually be melted, compressed, and injected into the mold’s runner system. Hot resin is shot into the mold cavity through the gates and the part is molded. Ejector pins facilitate removal of the part from the mold where it falls into a loading bin. When the run is complete, parts (or the initial sample run) are boxed and shipped shortly thereafter.