Impresión 3D de creación rápida de prototipos: la evolución de la impresión 3D

La historia y la importancia de la impresión 3D de creación rápida de prototipos

Desde el principio, la creación rápida de prototipos se encuentra entre los principales beneficios de la fabricación aditiva. Inicialmente, tomó días, semanas e incluso meses diseñar y desarrollar un prototipo, pero gracias a la rápida impresión 3D de prototipos, el proceso ahora lleva horas. Esta disminución significativa en el tiempo permite que las ideas innovadoras y las ideas únicas lleguen al mercado en un plazo mínimo.

Since additive manufacturing has increased the speed of product design and development, therefore, it has become a huge success across industries. With 3D printing, it now possible to move from ideation to production in an efficient manner. As creation functional and durable prototypes now take a fraction of the time in comparison to the time required for the conventional methods.

In this blog post, we are going to look at AM and rapid prototyping as well as how it impacts the product development cycle.

Introduction to Rapid Prototyping

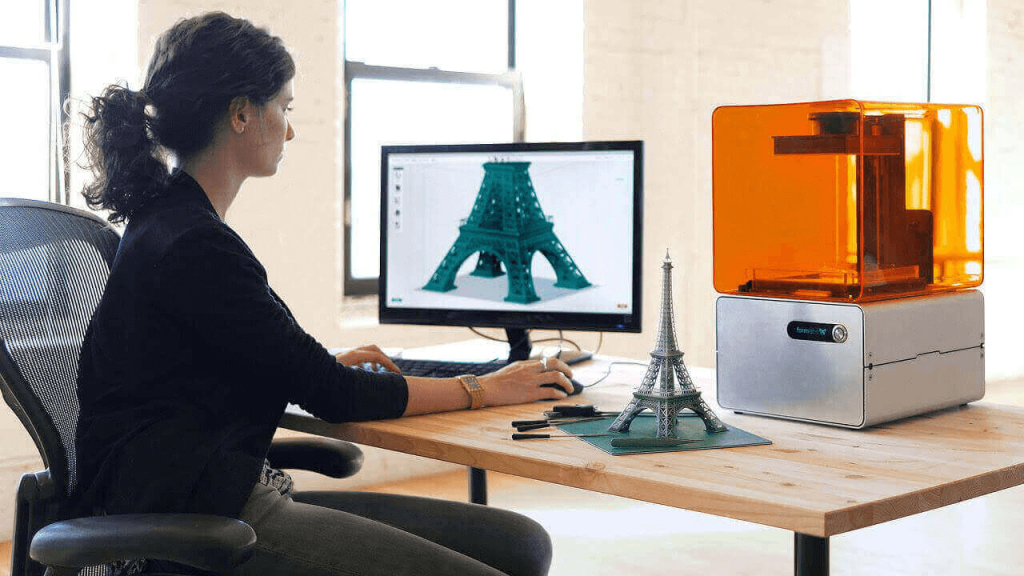

Rapid prototyping refers to the development and creation of prototypes and models using CAD data. These models are solid and fully functional. They are the perfect way to validate your idea during the product development stage.

There are numerous benefits of rapid prototyping. Of course, there are other methods that you can use for prototyping such as injection moulding. However, these methods might not be a feasible choice as they have high tooling costs. Moreover, it is difficult to make quick changes to the prototype models.

The need for faster speed to market and innovative solutions has resulted in the development of refined processes. These processes are particularly required for the speedy development of prototypes. This is where 3D printing comes into play.

Rapid Prototyping 3D Printing Takes Prototyping to a Whole New Level

The arrival of 3D printing allowed product engineers, and designers to the prototyping process to an entirely new level. The great thing about this technology is that it is toolless. Therefore, you would not have to bear the heavy cost of expensive tooling.

In addition, to take much lesser time to produce parts, the prototyping methods are effective for low-volume production as well. It means that 3D allows faster, cheaper, and reliable production of parts. These parts have consistency even in different batches. The reason being the parts use a digital CAD file to create a prototype. You can easily make changes to the prototype by altering the file.

The 3D Printing Technologies

There is no denying that the emerging rapid prototyping 3D printing has taken the industry to new heights. It is possible to acquire functional prototypes within the house and with a wide range of materials including metals and plastics.

Here are some of the new 3D Rapid prototyping Technologies

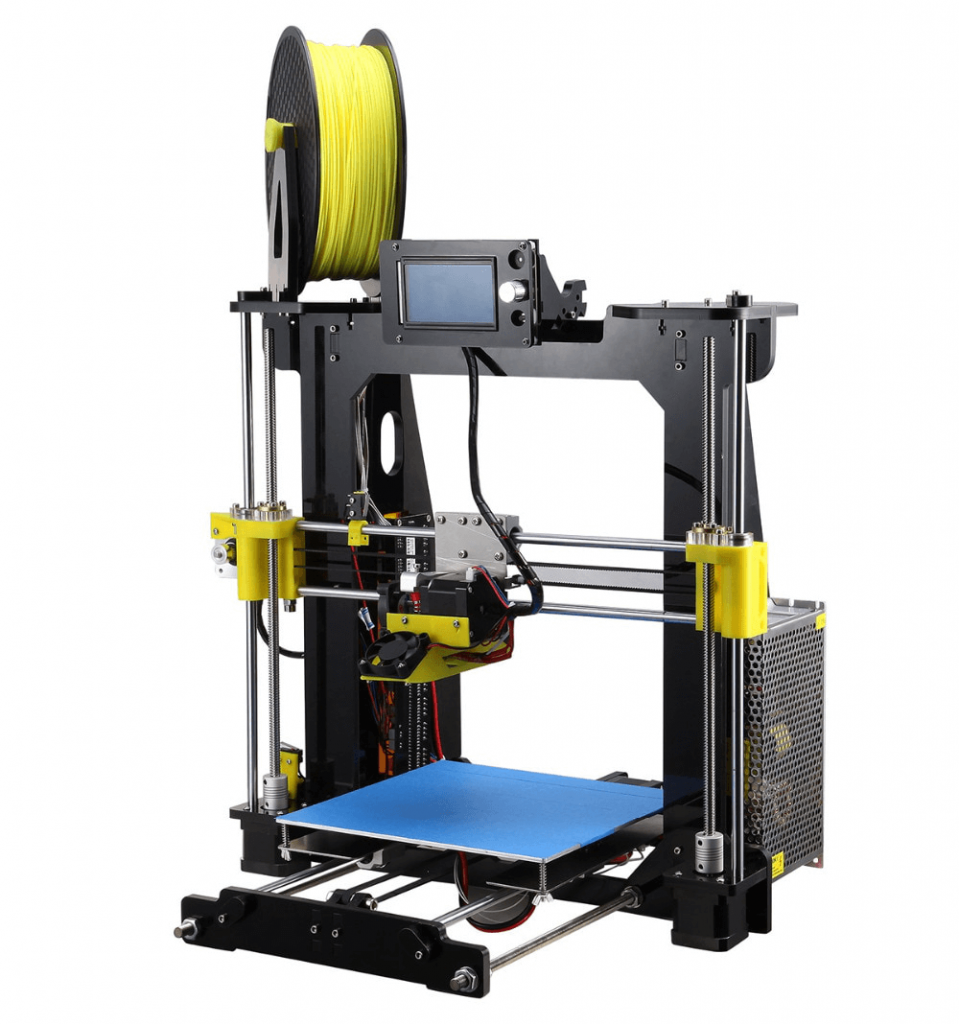

Fused Deposition Modeling

In the 1990s, Stratasys introduced this amazing concept. Fused Deposition Modelling is among the most common 3D printing technologies. It yields highly effective and efficient results. In 2009, several Fused Deposition Modeling patents experienced. The reason being, the companies shifted their focus towards the Fused Deposition Modelling 3D Desktop printers.

They were even able to acquire these printers at a low cost. Thus, making them an excellent choice for companies as well as for hobbyists.

The Working of FDM

In the FDM process uses layer by layer concept to extrude the thermoplastic filaments onto the printing platform. The modern FDM process supports a range of materials. It is possible for fabricantes de to select between thermoplastics having different properties.

They can use the durable ABS or elastic TPU. The process also ensures greater flexibility in the production process.

Multi-Material and Full-Color Prototyping

Binder & Material Jetting

Thanks to technological advancement it is now possible to design not only fully functional but also colors and eye-catching prototypes. The concept of multi-material and colorful 3D started at the beginning of the 2000s.

Este avance abre las puertas a varias oportunidades emocionantes. Los prototipos creados con esta tecnología fueron réplicas exactas del producto final.

Aglutinante y chorro de material

Estas son las dos tecnologías principales que permiten la posibilidad de crear prototipos exactamente como el producto final. Las posibilidades multicolores también ofrecen otras ventajas. Por ejemplo, ayuda a agilizar el proceso de acabado posterior al procesamiento.

Dado que el cliente sabría exactamente cómo se vería el producto, puede realizar cambios en los acabados finales como el color o la textura de la superficie. Aunque ambas tecnologías tienen el mismo resultado, existe una diferencia en su mecanismo de trabajo.

En el chorro de material, el proceso deposita las gotitas de resina fotocurable, mientras que el chorro de aglutinante fusiona polvos plásticos mediante un agente aglutinante.

In addition to creating a colorful 3D printed Prototype, Material Jetting also offers the facility of creating parts that require a combination of different material properties. Thus, offering a lot of opportunities to design and develop models that would perform all the functions of the product’s final part.

Metal Prototyping

Some industries including the automotive and aerospace require the one-off functional metal prototypes. They want these prototypes to authenticate the part performance. Thanks to rapid prototyping 3D printing, it is now possible to create prototypes using metal even.

After all, 3D printing does reduce the material waster, offers greater design freedom and it is a toolless production. All these advantages make it an attractive and appealing option to create fully functional and accurate prototypes.

El fabricantes sofisticados están incorporando tecnología más nueva y mejor para mejorar las técnicas generales de impresión 3D. Por ejemplo, los fabricantes ahora utilizan sistemas de moldeo por inyección de metal para imprimir piezas de metal.

Pueden producir resultados más efectivos en menos tiempo y costo, especialmente cuando los compara con impresoras 3D.

Nota: Si su objetivo es crear cantidades mayores, se recomienda utilizar las tecnologías tradicionales como la fundición o el mecanizado CNC. La impresión 3D es una mejor opción para crear modelos que tienen características internas complejas y las necesita en un número menor.

Para llevar

La impresión 3D de creación rápida de prototipos ha recorrido un largo camino desde su introducción. Ahora es la forma líder y más eficaz de crear prototipos funcionales, sólidos y precisos. Si está buscando un fabricante de prototipos confiable, profesional y experimentado, comuníquese con nosotros hoy mismo.

Le proporcionaremos toda la información requerida.