How CNC machines are important in machining car parts in 2021?

A CNC machine is a type of machine that has the control from the computer. This machine works when we feed the program for its functioning. This machine works with CAD and CAM. This article will provide you important information about the CNC machines, their common types, price of development of the CNC Machining Car Parts and the important parts of the CNC machines.

What are the 5 common types of CNC machines?

There are many common types of the CNC machines that are available in the market. But some of them have become common and are famous for their numeric control functions. Some of these types are as follows:

Ø CNC Router

The CNC routers are the numeric control machines that are important in the cutting purposes. They have the important use in the cutting of different metals and CNC Machining Car Parts. The common types of the materials that are easy to cut with these router machines are steel, plastic, wood and other metals.

Ø Plasma cutters

The plasma cutters are the CNC machines that have very high precision and accuracy in the cutting function. These plasma cutters use the beam of plasma torch in order to cut the metal at the precise and exact location. The cutting with these plasma cutters is cleaner as compared to the products of other CNC machines. Therefore, these CNC machines are the best machines for the manufacturers.

Ø Laser cutters

The laser cutters are the CNC machines that use the laser beam in order to cut the metals. These CNC machines are also precise and accurate in the cutting of the materials and in CNC Machining Car Parts. The CNC laser cutting machines direct the high-power beam of laser light on the particular surface of the metal or material from where it has to cut it.

The finishing product of these machines is highly accurate and fine. They can evaporate and burn the part of the material where they direct the beam of laser light. Therefore, they are able to get the high quality and fine cutting of the product.

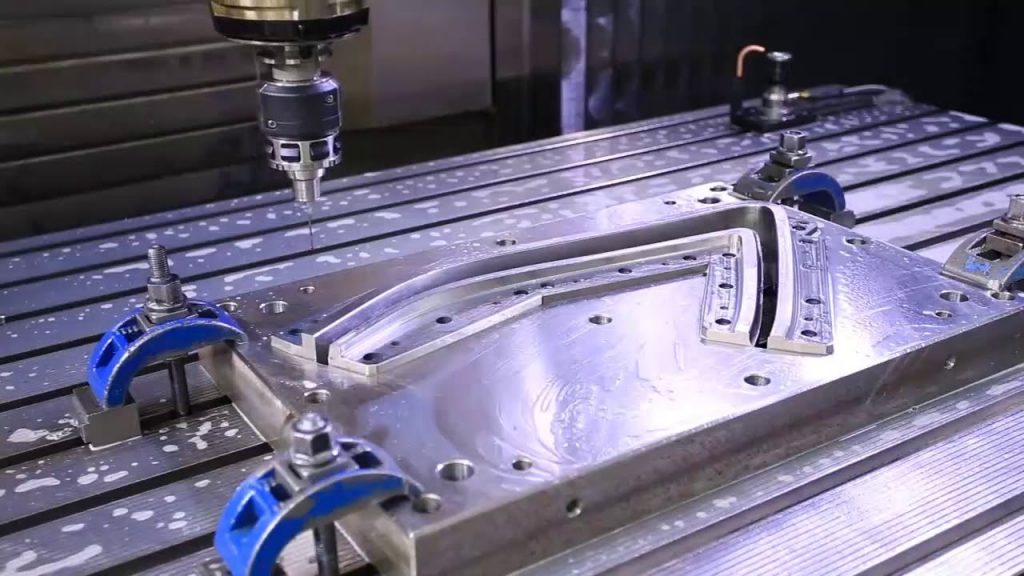

Ø Milling machines

These milling machines are the efficient and multifunctional CNC machines. They have the primary and fundamental use in the cutting of the metals in order to make different parts. They cut the materials at the different sites in order to make the parts of different shapes.

These CNC milling machines are best for the different types of the uses. They can produce the milling parts that have the important use in different types of the industrial applications. They can perform the milling, tapping and drilling at the same time. That is why these CNC milling machines have the preferred use as compared to the cutting machines for CNC Machining Car Parts.

Ø JKR Large Format CNC Router

The JKR large format CNC router machines are available in different types of the forms and sizes. They also provide the facility of changing the tools for the different applications. The size of the machine enables the user to easily move it at any time without the disturbance and damage.

These machines are available with the high quality and efficient parts that are easy to move without causing any disturbance. These machines have heavy M24 legs that are much helpful in the operations of different kinds.

Ø Axiom CNC router

The axiom CNC router machine is a small type of the CNC cutting machine. This machine has the wide use due to its small size and precision. These types of the CNC machines are best for the cutting operations at the small levels. These CNC machines provide the ease for the cutting keeping portability in consideration for CNC Machining Car Parts.

Who is the father of CNC machine?

The numeric control of the devices is an important mile stone that was the great success in the electronic field. Parsons was the first person who was able to inculcate the numeric control in the electronic tools and devices in 1940s. While the first person who was able to develop the CNC milling machine for the first time was Richard Kegg in 1952.

Richard Kegg was also the person who filed a patent name “Motor Controlled Apparatus for Positioning Machine Tool” in 1958. With these achievements, the age of numeric control technology started and is now in its current advanced form. Now we can use them in an efficient way for the purpose of CNC Machining Car Parts.

What is a 5 axis CNC machine?

The 5 axis CNC machine is a type of the CNC machine that is able to rotate the cutting part in 5 axes simultaneously. The traditional CNC cutting machines are able to move or rotate the part in 3 axes that are X, Y and Z. However, these CNC machine can rotate them in two additional axes that are A and B.

The 5 axis CNC machine is best to provide the efficient and cost-effective design in the manufacturing of the certain parts. Due to the 5-axis rotation, we can get the complex and sophisticated designs with easy moves. However, the generation of the complex designs was not easy with the other machines.

Hw much does it cost to CNC machine a part?

The CNC machines are available in the different forms and varieties. With the different types of the machines and their architecture, the cost and pricing of the CNC Machining Car Parts vary to much extent. The cost of the overhead machine is much greater that is as much as three times to the CNC machining and 3D printing.

The cost evaluation for the CNC milling machine is almost $40 per hour. In this process, there are separate charges and cost for the operator to do the task of cutting or milling. While the CNC turning is cost effective as compared to CNC milling machine that is $35 per hour. However, the cost of multidirectional CNC cutting machine is $75 to $120 per hour.

From this assessment of the cost values, we can say that price of owning a CNC machine is almost equal to the expenditure of a 3D printer. However, in the case of cutting the metal, the cost can decrease to much lower value as compared to this.

What are the parts of CNC machine?

The important parts of a CNC machine are following:

- Bed

- Headstock

- Tailstock

- Tailstock quill

- Footswitch or pedal

- Chuck

- Control panel

- Tool turret

The bed of the CNC machine is the compact and hard part of the machine. The reason behind the compactness of the bed is that the torrent has to run over this bed of the machine. The headstock of the machine is the fundamental part of the machine that has the motor with it.

The workpiece on which the machine has to perform the operation, is present on the headstock of the machine. The motor that is present with the headstock helps to move and drive the spindle of the machine. The tailstock is the supporting part of the machine that provide grip and support to the workpiece under consideration during CNC Machining Car Parts.

Conclusion

The main spindle of the machine has an important part with it that is chunk. Chunk is the part where we fix the workpiece for the cutting operation. While the control panel of the machine is for the feeding the program to the machine. The tool turret of the CNC machine is for the purpose of component machining.