LA DIFERENCIA ENTRE MECANIZADO CNC E IMPRESIÓN 3D

A medida que la tecnología avanza y revoluciona la ingeniería y la maquinaria, desea saber que está utilizando el mejor equipo y liderando su negocio. Algunos de estos avances se encuentran en el mecanizado de control numérico por computadora (CNC) y la impresión 3D. Ambos trabajan con diferentes materiales. Pero, ¿cuál es mejor para tus necesidades?

CNC machining and 3D printing have similarities and differences, and each has unique benefits. They have varying circumstances where you would want to use them regarding cost and availability. Breaking down each manufacturing style will help you pick the best method for you and your business.

Their main differences occur in production, waste, scale, material availability and size of the parts.

SIMILARITIES BETWEEN CNC AND ADDITIVE MANUFACTURING (3D PRINTING)

CNC machining and additive manufacturing are both computer-controlled solutions to making products out of a given material. They’re both machines at the forefront of building technology safely and efficiently.

As machinists and engineers want to build a prototype, a part or a custom product, they can turn to one of these machines to do the job for them. As long as the machines have the design, you don’t have to worry about human error because the machines are automated. While this doesn’t mean issues don’t arise, there’s more consistency with production and less chance of injury.

There is some overlap with these two manufacturing methods. Some CNC machines can use STL and OBJ files, which 3D printers also accept.

La maquinaria CNC es más antigua que la impresión 3D y todavía tiene una presencia más sólida en la fabricación. La forma comenzó en la década de 1940 y se había moldeado para adaptarse a la industria hasta el presente. La impresión 3D apareció en 1986. Todavía es relativamente nueva y está evolucionando para ser más accesible y versátil. La impresión 3D puede ayudar en algunas áreas de la creación de prototipos, pero no es una herramienta de reemplazo para el mecanizado CNC.

No son tanto alternativas al otro, ya que ambos son aspectos del mundo de la fabricación. Satisfacen diferentes demandas y manejan diferentes materiales y mercados. Las máquinas CNC y la impresión 3D tienen capacidades y limitaciones únicas que se adaptan a ellas para trabajos específicos. A medida que encajan en sus nichos de mercado, querrá compararlo con cualquier industria en la que se encuentre.

DIFERENCIAS ENTRE MECANIZADO CNC E IMPRESIÓN 3D

From their building methods to what applications they can handle, CNC machining and 3D printing offer creative solutions in vastly different ways. Finding out their differences and strengths will help you find which one is right for you and your business.

3D printers are typically more efficient than traditional manufacturing. The printer uses the materials that make up the item it’s creating, whereas traditional manufacturing methods such as CNC Machining require more materials for the mold to work. On average, 3D printers produce less waste than traditional manufacturing methods.

However, when production is large-scale, traditional manufacturing methods have a distinct advantage. Assembly lines are faster than a 3D printer in mass production because printers build layer by layer. In the hours that it could take to 3D print a product, an assembly line could have mass-produced hundreds of the same product.

Additionally, 3D printers can only use the area of the printing bed for making parts. Large-scale parts might not fit in that space. While the parts can be broken down into smaller pieces 3D printers can build, that might not be cost-effective and will take time. Traditional manufacturing has the advantage of the assembly line’s labor and will be able to produce items on a larger scale. Future 3D printers could be able to build larger items, but not on the level of what CNC machines offer with regard to quality and quantity.

3D printers can manipulate different materials such as plastics, metals and polymers. However:

- Not all 3D printers can use these materials. It takes separate machines for each material.

- 3D printers cannot work with every material that traditional manufacturers use due to high melting points.

- Some projects might not be able to consider using 3D printers if they require specific materials that are incompatible with the printers.

Here is the bottom line — 3D printing won’t replace traditional manufacturing because of its disadvantages in mass-produced items.

3D Printing vs. Traditional Manufacturing

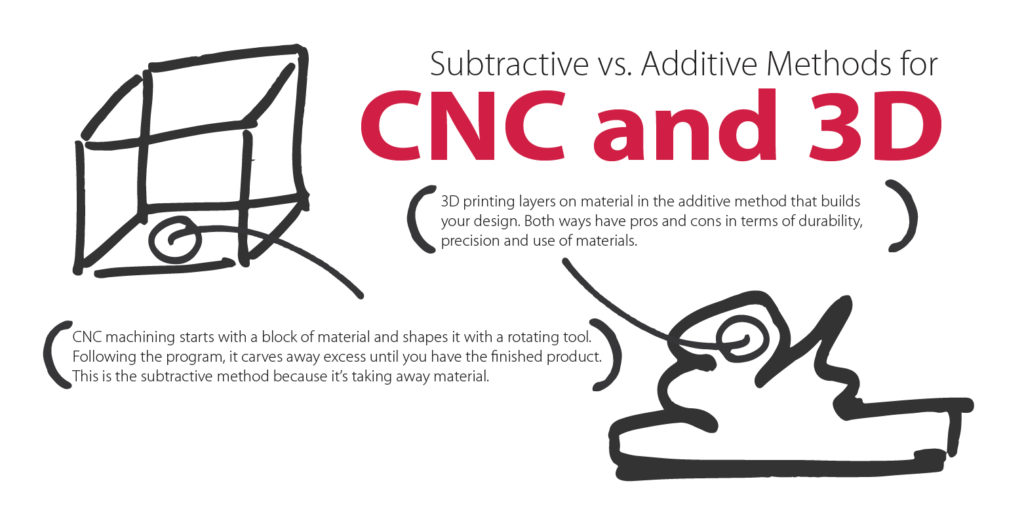

CNC machining starts with a block of material and shapes it with a rotating tool. Following the program, it carves away excess until you have the finished product. This is the subtractive method because it’s taking away material.

Capas de impresión 3D sobre material en el método aditivo que construye su diseño. Ambas formas tienen pros y contras en términos de durabilidad, precisión y uso de materiales.

Uso de material para CNC y 3D

El mecanizado CNC funciona con una variedad de materiales. Pueden usar:

- Aleaciones de metales

- Bosque

- Acrílico

- Espuma de modelado

- Termoplásticos

- Cera de mecanizado

Las máquinas CNC tienen sistemas de calefacción que pueden manejar materiales pesados. Estos materiales se utilizan para construir piezas sustanciales para motores, aviones y otras máquinas. Deben ser exactos, fiables y duraderos. Las herramientas de corte para el diseño pueden tener que cambiar, pero la mayoría de las herramientas están estandarizadas para adaptarse a cualquier máquina CNC.

3D printing doesn’t have this variety, using materials like plastics or resins. They can’t produce items strong enough to withstand intense environments like airplanes or other machinery. Also, 3D printers can’t switch between materials. Certain 3D printers are for specific kinds of material.

3D and CNC Precision of Production

CNC machining is more precise and consistent than 3D printing because they have a higher tolerance for heat. 3D printers end up with distorted products when there’s too much heat. They can offer precision but cannot remain consistent. 3D printers are often regarded as more user-friendly than CNC machines, but when they malfunction, someone has to troubleshoot them because the fault means production of unusable products.

CNC and 3D Speed of Production

CNC is a faster solution than 3D printing. Automated CNC machines can work around the clock as long as they’re properly maintained. A project that could take CNC machining an hour would equate to a 3D printer taking hours to get the final product because it has to build the product layer by layer. A 3D printer’s pace might have to slow down during the process to get the design right. Different 3D printers could also be programmed with specific speeds that you can’t alter. It depends on the machine you use.

Los productos impresos en 3D también requieren trabajo después de su construcción. Los productos deben lavarse, pulirse y sellar antes de que las personas puedan usar el producto. Esto podría extender las pruebas de prototipos a un período de tiempo más largo con mucha espera en el medio. Las impresoras 3D también son populares para artículos más pequeños fabricados a medida. Pero si tiene que esperar a que se construya el artículo y aún hacer mucho trabajo después de la impresión, pierde mucho tiempo antes de poder mover el producto.

Versatilidad de maquinaria para CNC frente a 3D

Las máquinas CNC pueden producir accesorios, herramientas y piezas diseñadas a medida. Tienen una amplia gama de configuraciones de calidad para que pueda hacer un prototipo que tenga un diseño más tosco en algunas áreas y perfecto en otras para que pueda probar esa parte.

When testing prototypes for a project, a CNC machine could quickly build a design so the developers can test it. 3D printers don’t have these kinds of options. It will slowly shape the design as it was programmed. Accuracy is key when constructing a final product, but when time is a constraint and you want to test some prototypes, 3D printers can slow down you and your project. Designs made for a CNC machine usually can’t be substituted with a 3D printer because the products are voluminous and it would take hours for a 3D printer to finish them.

Noise and Mess Produced by CNC and 3D

These differences relate to the subtractive and additive methods. CNC machining is much more noisy and messy than 3D printing because it uses a tool to cut away material. This creates noise and a lot of scrap metal or wood shavings. CNC machines cause a lot of vibrations, so they need to be in a space where they won’t bother anyone. 3D printing only uses the material it needs for the product. There’s little to no waste, and the printers don’t vibrate like a CNC machine.

Applications for CNC and 3D

CNC machining can manufacture bigger products and can handle heat-resistance. 3D printing has more niche categories, such as printing food or working in space.

CNC Machining vs. 3D Printing

According to World Finance, 3D printing is not a solution that can replace CNC machining. 3D printing is a part of the manufacturing world, but it’s not the invention that’s going to change the market as everyone knows it.

3D printers can improve certain aspects of manufacturing but cannot handle the whole market, as CNC machining still works better in many situations. CNC machining still offers better quality than expensive 3D printers.

On a smaller production scale, 3D printers have an edge in saving businesses money from buying expensive molds. They also offer an insight to the product’s shape and aesthetic. But as production increases and time factors in, they don’t hold up as well as CNC machines.

BENEFITS OF CNC MACHINING OVER 3D PRINTING

CNC machining fits with mass production. It can create many products in a shorter period, where 3D printing would take hours to create one product. That’s just one advantage of CNC. Let’s take a look at some others.

Prototyping Becomes Easier

CNC machines are better for prototypes that can withstand structural tests because they carve the design from the material. They can also build prototypes out of the exact material that will be used to make the final product.

Structural tests and alterations will be more accurate because they use the same material. This could speed up the production process because the changes will be to the design and not the material. 3D printers don’t fabricate prototypes with the structural strength, so they can’t conduct physical tests.

Prototype Integrity Improves

CNC machines don’t heat the material and reform it. The material stays stronger and has a better structural integrity than 3D printers, which have to heat the material to build the intended product. 3D printers might also have to add foreign materials to the mixture to be able to make the prototype, which CNC machines don’t need.

Surface Finish Advantage

CNC machines provide better surface finish than 3D printing because the materials don’t deform during the process. The rigid material and cutting action keeps the product together and has fewer chances for mistakes or deformations to occur. 3D printing has poorer surface finish. The material bends, warps or distorts because the material is layered heated plastic.

Tolerance Levels Rise

CNC machines work with higher precision, so the parts have a better tolerance than 3D printers. Because of tolerance level, prototypes that have shafts or connect to other parts will be higher quality and will more likely fit with other components.

Price and Volume Don’t Dictate Price

3D printing costs depend on the volume of needed materials. Final product volume doesn’t dictate the price for CNC machines. 3D printing wouldn’t be cost-effective with larger orders, and this is the situation where CNC machines thrive.

Quality in Favor of CNC

Larger layers from a 3D printer are faster but not as high-quality as smaller layers. If you need a prototype, you have a choice to get it fast but of slightly less quality, or wait longer for the prototype with the best quality the printer can provide. CNC machines have the option for you to choose resolutions for your item. They can offer varying qualities in a short amount of time, making them ideal for quick builds and immediate results for testing.

Keeping Costs Down

If you have the option of choosing which manufacturing method to use for your product, CNC machining is usually cheaper than 3D printing.

Contact Kaito mould Works, Inc., for Your CNC Machining Needs

El mecanizado CNC puede construir las piezas que necesita para su negocio. Nuestros maquinistas expertos en Kaito Mold Works, Inc., brindarán un trabajo excepcional que lo ayudará a alcanzar sus metas. Nuestro objetivo es ayudarlo a obtener la pieza correcta para su proyecto.

Kaito Mold Works, Inc., brinda servicios para la construcción de máquinas personalizadas, máquinas de piezas de precisión e ingeniería inversa de componentes para brindarle el producto que necesita rápidamente. Ofrecemos excepcionales soluciones de mecanizado CNC para fabricantes de múltiples industrias. Nuestra habilidad en la especialización y dedicación a nuestro trabajo le ayudará a usted y a su empresa a mantenerse a la vanguardia de la industria. Tenemos las soluciones que necesitas. Ponte en contacto con nosotros hoy.

Si podemos ayudarlo con su proyecto, llámenos al 0086-769-82821468 o envíe un .