Combien ça coûte d'embaucher un fabricant d'injection plastique en 2020?

Avantages les plus populaires de la technologie de moulage par injection plastique

introduction de la technologie du fabricant d'injection plastique

fabricant d'injection plastique est assez célèbre dans l'industrie des produits en plastique. Chaque industrie utilise plusieurs produits en plastique. De même, la portée de l'activité humaine y est également associée. L'utilisation de plastique depuis les matériaux de construction et les appareils ménagers jusqu'aux ustensiles de cuisine.

The most popular method for manufacturing various products is plastic injection manufacturer technology. Moreover, modern equipment provides an opportunity to automate the production process.

And receive products with excellent technical characteristics in a short time with minimal investment. Polymer products are recyclable. Therefore, they are environmentally friendly material.

What is plastic injection manufacturer molding procedure?

Injection molding is a manufacturing process in which liquid plastic is injected under pressure into a metal mold. Evenly distributed over it and solidifies. Subsequently, this is the most common method of large-scale manufacturing of plastic products.

The injection molding process requires sophisticated equipment and serious technical training. However, under the supervision of experienced professionals, the costs justify themselves. And the result is a product of excellent quality.

Large-scale and mass production of plastic parts involves a complex process. For injecting molten plastic under high pressure into a prepared injection mold made of metal. Furthermore, the liquid mass evenly fills the volume and crystallizes, acquiring the desired shape.

Thanks to fabricant d'injection plastique molding technology. Moreover, it is possible to obtain high-quality products. To implement the method, sophisticated expensive equipment is used that provides high performance.

Using this method, almost half of the polymer parts are produced. Granules of thermoplastics, as well as thermosetting powders. Which give finished products the required physical and operational qualities. Simultaneously, these are used as raw materials for the production process.

fabricant d'injection plastique application for injecting technology

Using this method, you can produce almost any plastic product. There are no restrictions on the size or number of parts. Here is a partial list of what can be produced fabricant d'injection plastique technology:

- enclosures for electronic equipment;

- automotive components;

- plastic caps and caps;

- cases for medical equipment;

- household appliance parts;

- Kids toys;

- plastic packaging, etc.

Benefits of fabricant d'injection plastique molding technology

Many fabricant d'injection plastique choose a cheaper method of production – casting in silicone mold. However, often this choice brings even greater cash costs. And does not guarantee excellent quality.

Why is it recommended to choose fabricant d'injection plastique in making large batches?

High accuracy of the finished product. The supply of liquid plastic under pressure allows it to evenly distribute in shape, filling even the smallest holes.

The ability to receive parts of any complexity, including with very thin walls. For the manufacture of products, a metal mold is made. Similarly, the design of which takes into account all the small details of the future product.

En conséquence, le fabricant d'injection plastique peut obtenir un produit à la fois simple et très complexe, avec de nombreux trous et plis.

Le besoin minimum d'usinage du produit. Le plus souvent, le produit fini ne nécessite aucun traitement. De plus, les exceptions sont des produits très complexes. Cependant, dans ce cas, les améliorations sont minimes.

Produits finis illimités.

Le moule métallique, qui est créé avant la production, durera très longtemps. Par la suite, avec son aide, vous pouvez fabriquer n'importe quel nombre de produits.

Faible coût sous réserve de la fabrication d'un lot important.

Plus il y aura de produits fabriqués, moins le coût d'une copie sera bon marché. Parce que le budget principal est dépensé au stade des travaux préparatoires. Par conséquent, il n'est effectué qu'une seule fois.

At the same time, fabricant d'injection plastique technology has its drawbacks.

- the high cost of preparatory work, and

- accordingly, the unprofitability of manufacturing a product in a single copy or in a small batch.

THE MAIN STAGES OF THE PRODUCTION OF THE PRODUCT BY INJECTION MOLDING

The process of manufacturing plastic products by injection molding involves several stages. Generally, it can be divided into two groups:

- preparatory work and

- casting itself.

Let’s consider these stages in more detail.

Preparatory work

Creation of 3D models of the future product. You can create a 3D-model according to the drawings, description or photograph. Three-dimensional modeling is carried out in a special program by an experienced specialist.

Prototype manufacturing.

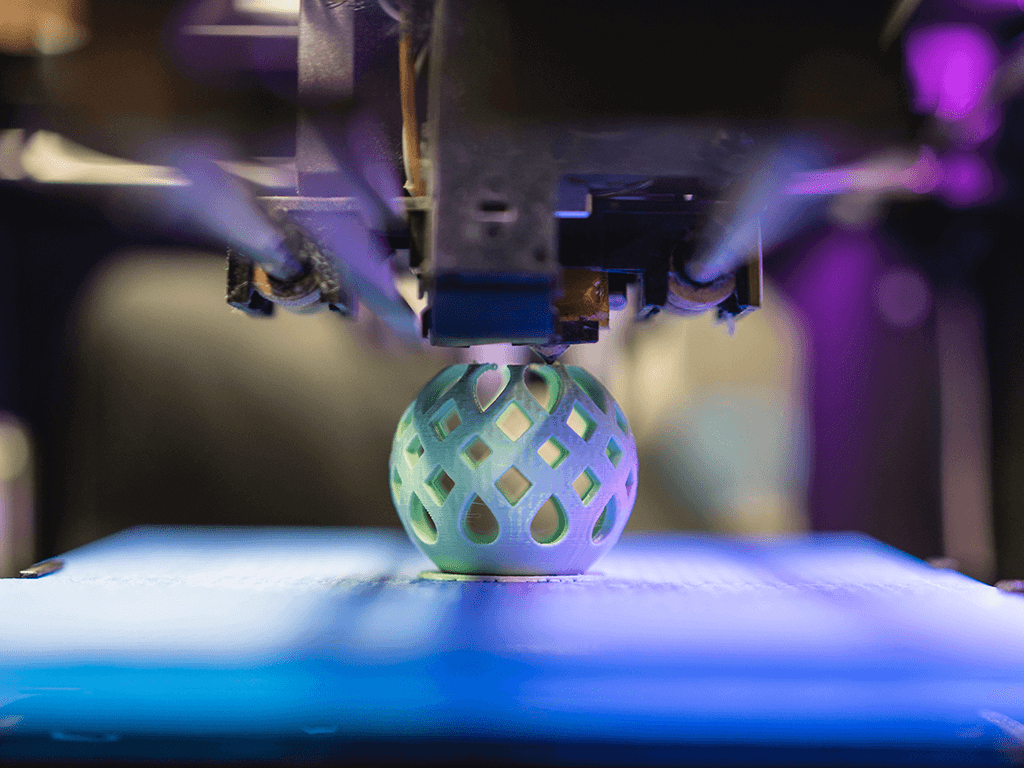

Une fois le modèle 3D créé et approuvé, vous pouvez créer un prototype, c'est-à-dire un échantillon du futur produit. Cela se fait le plus souvent en utilisant l'impression 3D.

Un prototype est nécessaire pour évaluer et tester le futur produit.

Si des inexactitudes ont été trouvées, il est nécessaire de revenir à la première étape et de finaliser le modèle 3D.

Conception de moule.

Ce processus est basé sur un modèle 3D du futur produit. Lors de la conception, il est important que les fabricants d'injection plastique prennent en compte tous les moindres détails et subtilités.

Fabrication de moules.

Le modèle 3D fini est divisé en plusieurs parties. De plus, chaque pièce est fabriquée séparément. Après quoi, ils sont assemblés dans un moule.

Test de moulage.

Next, using the finished mold, the first copy is made. Furthermore, it is carefully studied and tested. If inaccuracies or flaws were found, the mold is being finalized.

Preparatory work lasts from several weeks to several months. However, this is an important stage in which fabricant d'injection plastique should not rush. Because the quality of future products depends on it.

Injection molding process of plastic injection manufacturer

Submission of plastic to the mold under pressure. Moreover, the heated plastic is fed into the mold under high pressure.

Uniform distribution of plastic over the mold. Due to the pressure, the plastic is evenly distributed in shape filling even small holes.

Mold cooling and plastic hardening. Similarly, the cooling time depends on several parameters:

- type of plastic

- mold temperature, etc.

- For small items, this is usually a few seconds.

Delivery of the finished product.

After the mold has cooled, it opens to give the finished product.

What is the cost of plastic injection manufacturer for producing injection mo0lding product?

As a rule, the fabricant d'injection plastique by this method requires serious financial investments at the stage of preparatory work. However, the more pieces will be produced in the future, the lower the cost of one product. At the same time, quality remains high.

The production price is calculated individually, based on all of the product features. What the final cost may depend on

- The complexity of theThe higher it is, the more expensive the mold will be, and accordingly, each product.

- Type of plastic. The material is selected based on the requirements for the final product.

- Number ofpieces in a batch. The more of them, the cheaper each product, and other significant factors.

The advantages of plastic injection manufacturer technology

For the production of large batches of polymer products, fabricant d'injection plastique technology of plastics is characterized by the advantages of high precision casting. By injecting the molten mass at an increased rate, uniform filling of the mold is ensured, including microscopic holes. Generally, the method is characterized by many advantages, due to which it is popular:

- Possibility of manufacturing products of any geometric shape and degree of complexity.

- Thin-walled parts are made. The complexity of the design depends on the mold.

- Moreover, it has high detail and takes into account all the bends. As well as the holes of the future product.

- No need for plastic injection manufacturer for subsequent machining of parts.

- Similarly, some complex products may undergo minimal processing.

- Mass production of unlimited plastic parts. The life of metal molds is tens of years.

- So, they are used to manufacture a huge number of polymer products.

- Quick payback when organizing the production of a large batch of plastic products. At the same time, the cost of one product is reduced.

- without quality deterioration with an increase in the number of copies produced.

plastic injection manufacturer equipment features

La vie moderne n'est pas possible sans fabricant d'injection plastique plastique. Et ils sont dans n'importe quelle sphère et domaine. Un fabricant d'injection plastique doit répondre à toutes les exigences d'un client. Intéressé par la production de produits en plastique durables et de haute qualité. En résumé, l'équipement doit être adapté aux besoins du client.

Si nous pouvons vous aider avec votre projet, veuillez nous appeler au 0086-769-82821468 ou par e-mail un .