2020年にプラスチック射出製造業者を雇うのにどれくらいの費用がかかりましたか?

プラスチック射出成形技術の最も一般的な利点

プラスチック射出メーカー技術紹介

プラスチック射出メーカー は、プラスチック製品業界で非常に有名です。 すべての業界で複数のプラスチック製品が使用されています。 同様に、人間の活動の範囲もそれに関連しています。 建材や家電製品から台所用品までのプラスチックの使用。

The most popular method for manufacturing various products is plastic injection 製造 technology. Moreover, modern equipment provides an opportunity to automate the production process.

And receive products with excellent technical characteristics in a short time with minimal investment. Polymer products are recyclable. Therefore, they are environmentally friendly material.

What is plastic injection manufacturer molding procedure?

Injection molding is a manufacturing process in which liquid plastic is injected under pressure into a metal mold. Evenly distributed over it and solidifies. Subsequently, this is the most common method of large-scale manufacturing of plastic products.

The injection molding process requires sophisticated equipment and serious technical training. However, under the supervision of experienced professionals, the costs justify themselves. And the result is a product of excellent quality.

Large-scale and mass production of plastic parts involves a complex process. For injecting molten plastic under high pressure into a prepared injection mold made of metal. Furthermore, the liquid mass evenly fills the volume and crystallizes, acquiring the desired shape.

Thanks to プラスチック射出メーカー molding technology. Moreover, it is possible to obtain high-quality products. To implement the method, sophisticated expensive equipment is used that provides high performance.

Using this method, almost half of the polymer parts are produced. Granules of thermoplastics, as well as thermosetting powders. Which give finished products the required physical and operational qualities. Simultaneously, these are used as raw materials for the production process.

プラスチック射出メーカー application for injecting technology

Using this method, you can produce almost any plastic product. There are no restrictions on the size or number of parts. Here is a partial list of what can be produced プラスチック射出メーカー technology:

- enclosures for electronic equipment;

- automotive components;

- plastic caps and caps;

- cases for medical equipment;

- household appliance parts;

- Kids toys;

- plastic packaging, etc.

Benefits of プラスチック射出メーカー molding technology

Many プラスチック射出メーカー choose a cheaper method of production – casting in silicone mold. However, often this choice brings even greater cash costs. And does not guarantee excellent quality.

Why is it recommended to choose プラスチック射出メーカー in making large batches?

High accuracy of the finished product. The supply of liquid plastic under pressure allows it to evenly distribute in shape, filling even the smallest holes.

The ability to receive parts of any complexity, including with very thin walls. For the manufacture of products, a metal mold is made. Similarly, the design of which takes into account all the small details of the future product.

As a result, プラスチック射出メーカー can get both simple and very complex product, with many holes and bends.

The minimum need for machining the product. More often than not, the finished product does not require any processing. Moreover, exceptions are very complex products. However, in this case, the improvements are minimal.

Unlimited finished products.

The metal mold, which is created before production, will last a very long time. Subsequently, with its help you can make any number of products.

Low cost subject to the manufacture of a large batch.

The more products will be manufactured, the cheaper the cost of one copy. Because the main budget is spent at the stage of preparatory work. Hence, it is carried out only once.

At the same time, プラスチック射出メーカー technology has its drawbacks.

- the high cost of preparatory work, and

- accordingly, the unprofitability of manufacturing a product in a single copy or in a small batch.

THE MAIN STAGES OF THE PRODUCTION OF THE PRODUCT BY INJECTION MOLDING

The process of manufacturing plastic products by injection molding involves several stages. Generally, it can be divided into two groups:

- preparatory work and

- casting itself.

Let’s consider these stages in more detail.

Preparatory work

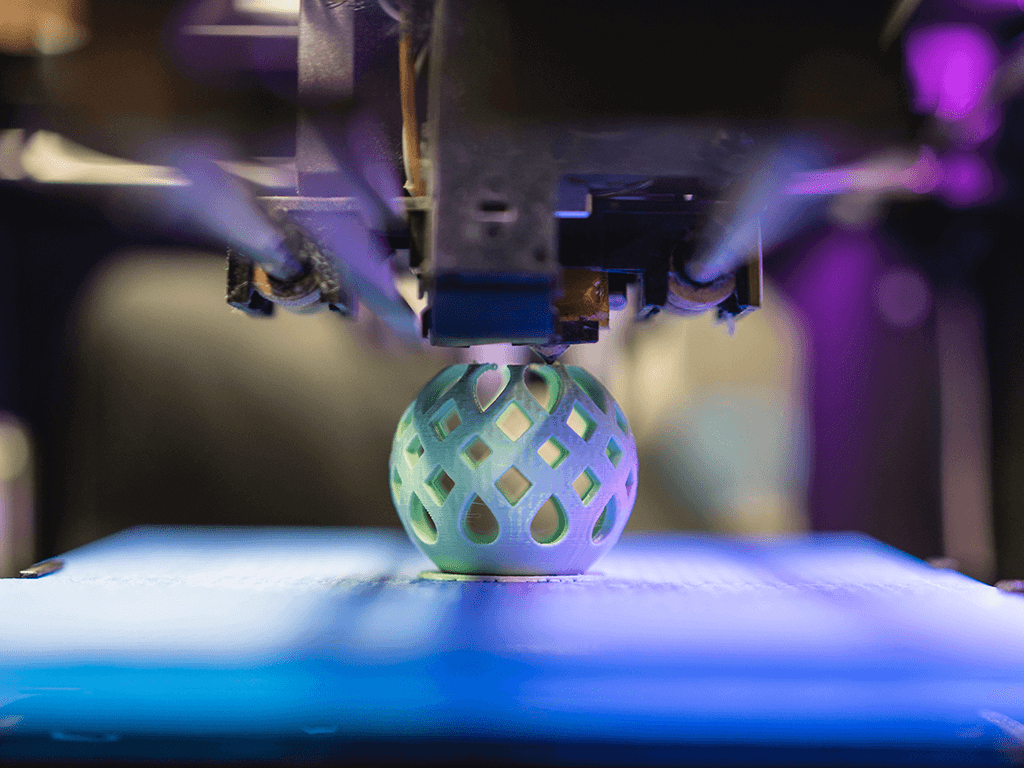

Creation of 3D models of the future product. You can create a 3D-model according to the drawings, description or photograph. Three-dimensional modeling is carried out in a special program by an experienced specialist.

Prototype manufacturing.

After the 3D model is created and approved, you can create a prototype, i.e. sample of the future product. This is most often done using 3D printing.

A prototype is necessary in order to evaluate and test the future product.

If any inaccuracies were found, it is necessary to return to the first stage and finalize the 3D model.

Mold design.

This process is based on a 3D model of the future product. When designing, it is important for the plastic injection manufacturers to consider all the smallest details and subtleties.

Mold making.

The finished 3D model is divided into several parts. Moreover, each part is made separately. After which they are assembled into a mold.

Test casting.

Next, using the finished mold, the first copy is made. Furthermore, it is carefully studied and tested. If inaccuracies or flaws were found, the mold is being finalized.

Preparatory work lasts from several weeks to several months. However, this is an important stage in which プラスチック射出メーカー should not rush. Because the quality of future products depends on it.

Injection molding process of plastic injection manufacturer

Submission of plastic to the mold under pressure. Moreover, the heated plastic is fed into the mold under high pressure.

Uniform distribution of plastic over the mold. Due to the pressure, the plastic is evenly distributed in shape filling even small holes.

Mold cooling and plastic hardening. Similarly, the cooling time depends on several parameters:

- type of plastic

- mold temperature, etc.

- For small items, this is usually a few seconds.

Delivery of the finished product.

After the mold has cooled, it opens to give the finished product.

What is the cost of plastic injection manufacturer for producing injection mo0lding product?

As a rule, the プラスチック射出メーカー by this method requires serious financial investments at the stage of preparatory work. However, the more pieces will be produced in the future, the lower the cost of one product. At the same time, quality remains high.

The production price is calculated individually, based on all of the product features. What the final cost may depend on

- The complexity of theThe higher it is, the more expensive the mold will be, and accordingly, each product.

- プラスチックの種類。 材料は、最終製品の要件に基づいて選択されます。

- Number of。 それらの数が多いほど、各製品が安くなり、その他の重要な要素があります。

プラスチック射出メーカー技術の利点

ポリマー製品の大量生産の場合、プラスチック射出メーカー 技術は、高精度鋳造の利点を特徴としています。 溶融塊を増加した速度で射出することにより、微細な穴を含め、金型の均一な充填が保証されます。 一般に、この方法には多くの利点があり、そのため人気があります。

- あらゆる幾何学的形状と複雑さの製品を製造する可能性。

- Thin-walled parts are made. The complexity of the design depends on the mold.

- Moreover, it has high detail and takes into account all the bends. As well as the holes of the future product.

- No need for plastic injection manufacturer for subsequent machining of parts.

- Similarly, some complex products may undergo minimal processing.

- Mass production of unlimited plastic parts. The life of metal molds is tens of years.

- So, they are used to manufacture a huge number of polymer products.

- Quick payback when organizing the production of a large batch of plastic products. At the same time, the cost of one product is reduced.

- without quality deterioration with an increase in the number of copies produced.

plastic injection manufacturer equipment features

Modern life is not possible without プラスチック射出メーカー plastic products. And they are in any sphere and field. A プラスチック射出メーカー equipment should meet all the requirements of a customer. Interested in the production of high-quality and durable plastic products. Summing up, the equipment should be customized to customer needs.

私たちはあなたのプロジェクトのお手伝いをすることができた場合は、下記にご連絡ください0086-769-82821468または電子メールsales@kaitomould.com.