中国プラスチック射出成形ラピッドプロトタイピングプロデューサー

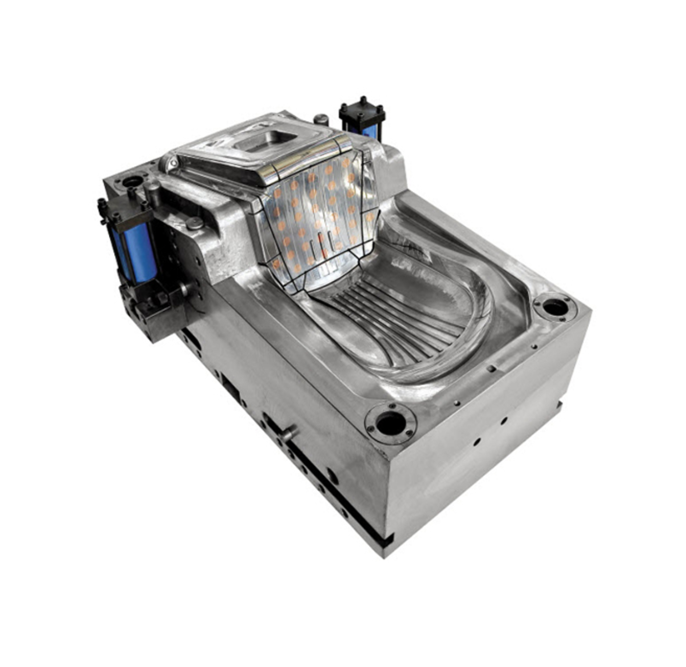

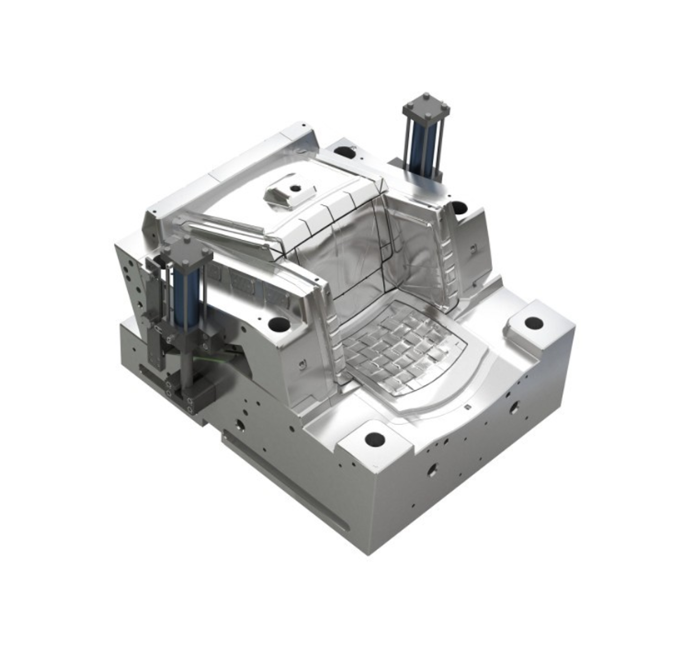

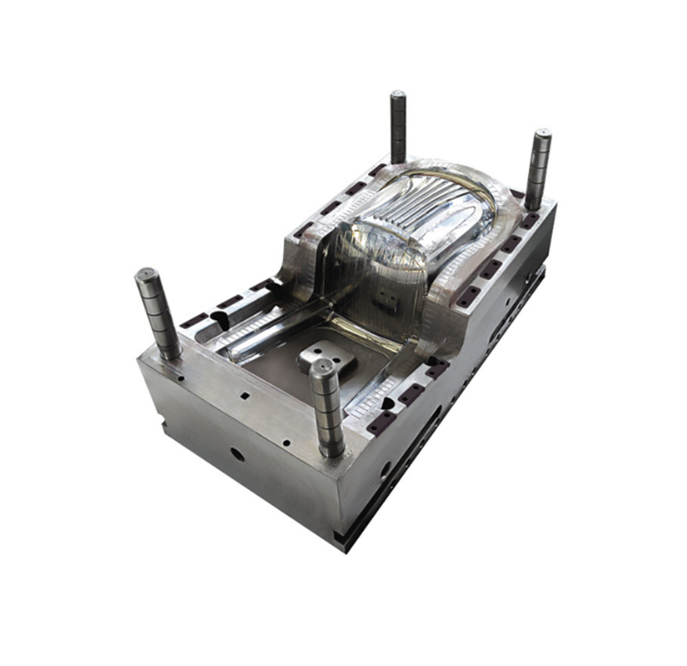

- プラスチック射出成形金型

- Pantone / RALおよびその他のカスタムカラー

- 研磨、電気めっき、窒化など。

- テクスチャ/サンディ/ MT / YS / SPI / EDM仕上げ/滑らか/光沢

- ISO 9001:2008

- お客様のご要望に応じて、海上または空路で。

Katioのプラスチック射出成形ラピッドプロトタイピング製品は、世界中のエンジニアが設計を実現するのに役立ちます。 当社は、高品質のアルミダイカスト部品を製造できる中国のダイカスト会社であり、CNC機械加工、表面処理、サブアセンブリ作業などのワンストップソリューションをお客様に提供しています。 Katioでは、お客様の[…]に基づいて金型を設計および製造できます。

製品詳細

Katio’s Plastic Injection Molding Rapid Prototyping products help engineers around the world make their designs a reality. We are a Chinese die-casting company that can produce high-quality aluminum die-casting parts and provides customers with one-stop solutions, including CNC machining, surface treatment, and sub-assembly work. At Katio, we can design and produce molds based on your exact specifications or samples. The extensive experience of our engineers enables them to eliminate any potential problems and provide you with high-quality die-casting molds that can be used to make high-quality and efficient die-casting products.

Custom Creating Plastic Injection Molds with Good Quality:

1. Katio Mould provides high-quality custom plastic injection molded parts.

2. Injection-molded parts can be different materials such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET Ect.

3. Different injection molded parts can pass different certifications such as UL test, V0 fire resistant test, FDA test, REACH test, SGS test and IP65.

4. Katio Mould can also provide different surface treatment for injection molded parts.

5. Commonly used surface treatment for injection molded parts as Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI.

6. Besides making injection molded parts, we also provide printing, welding, assembly, and packing service.

Our Service:

1. ID design and product development

2. CNC Prototype both for metal and plastic

3. Plastic injection mold

4. CNC machining service

5. Silicone/rubber reaction mold

6. Finished product assembly

One-stop Part Supply with Post-treatment:

- Oil painting

- Silkscreen printing

- Pad printing

- Laser engraving

- Soft-touch painting or rubber painting

- Hot stamping

- UV

- Oil painting & UV

- Ultrasonic welding

- Laser welding

- Electroplating

- PVD

Why Choose Us?

1. Our strong R&D and QC department can control the products to meet your strict requirements.

2. Different kinds of finish available, like anodized, powder coating, painting, polishing, electrophoresis, plating, etc.

3. Different dimensions according to the client’s request.

4. It can provide various sizes and pack according to specific requirements.

5. We offer the engineer consultation to your design for production improvement and cost-saving

6. Customized and tailored orders are welcome.

7. High quality and delivery in time.

8. OEM/ODM.

9. Our facture conforms to the ISO9001 standard.

High level of customization:

The technology used by our company allows the production of complex designs and provides us with the ability to customize the castings to match your specifications perfectly.

Efficiency:

Aluminum die casting is not only a way to easily customize products but also s very fast and efficient way to produce. Therefore, we can supply you with high-quality parts at a rate that will increase the overall efficiency of your production line.

Versatility:

The fact that die-casting aluminum parts are lightweight yet have high strength makes them suitable to use in a number of industry applications.

Corrosion resistance:

Aluminum alloy products offer a high rate of corrosion resistance which increases the wide range of use.

Low cost:

Aluminum dies castings are, in the long run, much more price-competitive than other aluminum casting methods such as gravity die casting and low pressure die casting.

| Product Material | Plastic |

| Shaping Mode | プラスチック射出成形金型 |

| Colors Available | Pantone / RALおよびその他のカスタムカラー |

| Mould shipping | お客様のご要望に応じて、海上または空路で。 |

| Surface Finish | テクスチャ/サンディ/ MT / YS / SPI / EDM仕上げ/滑らか/光沢 |

| Cavity material | P20,718,H13, 2316,2738,S136, and so on. |

| Drawing Format | STEP/STP/IGS/X-T/STL/CAD/PDF/DWG and Other |

| Cavity suirface treatment | 研磨、電気めっき、窒化など。 |

| Mold Life | 300000 shots to 1 million depend on the material of the mold |

| Gate type | Cold runner or hot runner as you require |

| Injection Machines | 26 |

人気

見積もりを取得

Yanhexi first road No. 3、Jinmei Village、Changping Town、Dongguan、China