လျင်မြန်သောရှေ့ပြေးပုံစံ 3D ပုံနှိပ်ခြင်း - 3D ပုံနှိပ်ခြင်းဆင့်ကဲဖြစ်စဉ်

Rapid ရှေ့ပြေးပုံစံ 3D ပုံနှိပ်ခြင်း၏သမိုင်းနှင့်အရေးကြီးပုံ

အစမှအလျင်မြန်သောရှေ့ပြေးပုံစံသည်ထပ်တိုးထုတ်လုပ်မှု၏အဓိကအကျိုးကျေးဇူးများအနက်မှတစ်ခုဖြစ်သည် ရှေ့ပြေးပုံစံကိုတီထွင်ရန်နှင့်ဖွံ့ဖြိုးရန်အတွက်ကန ဦး၊ ရက်၊ သီတင်းနှင့်လများပင်ကြာခဲ့သည်။ သို့သော် 3D ပုံနှိပ်ခြင်းလျင်မြန်စွာလုပ်ဆောင်ခြင်းကြောင့်လုပ်ငန်းစဉ်သည်နာရီများစွာကြာသည်။ အချိန်သိသိသာသာကျဆင်းခြင်းသည်ဆန်းသစ်သောအတွေးအခေါ်များနှင့်ထူးခြားသောအတွေးအခေါ်များကိုစျေးကွက်အတွင်း၌အနည်းဆုံးအချိန်အတွင်းရောက်ရှိစေနိုင်သည်။

Since additive manufacturing has increased the speed of product design and development, therefore, it has become a huge success across industries. With 3D printing, it now possible to move from ideation to production in an efficient manner. As creation functional and durable prototypes now take a fraction of the time in comparison to the time required for the conventional methods.

In this blog post, we are going to look at AM and rapid prototyping as well as how it impacts the product development cycle.

Introduction to Rapid Prototyping

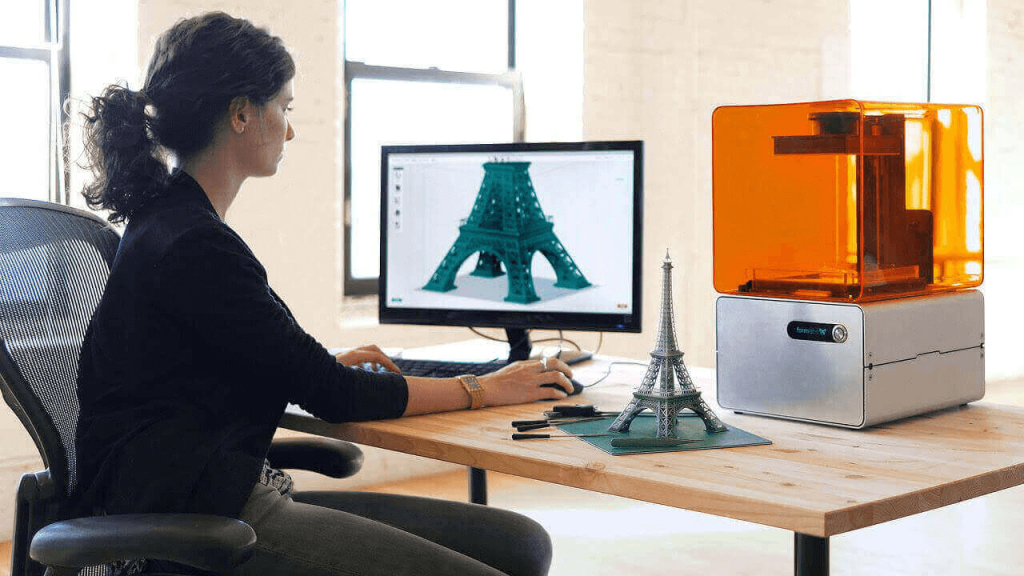

Rapid prototyping refers to the development and creation of prototypes and models using CAD data. These models are solid and fully functional. They are the perfect way to validate your idea during the product development stage.

There are numerous benefits of rapid prototyping. Of course, there are other methods that you can use for prototyping such as injection moulding. However, these methods might not be a feasible choice as they have high tooling costs. Moreover, it is difficult to make quick changes to the prototype models.

The need for faster speed to market and innovative solutions has resulted in the development of refined processes. These processes are particularly required for the speedy development of prototypes. This is where 3D printing comes into play.

Rapid Prototyping 3D Printing Takes Prototyping to a Whole New Level

The arrival of 3D printing allowed product engineers, and designers to the prototyping process to an entirely new level. The great thing about this technology is that it is toolless. Therefore, you would not have to bear the heavy cost of expensive tooling.

In addition, to take much lesser time to produce parts, the prototyping methods are effective for low-volume production as well. It means that 3D allows faster, cheaper, and reliable production of parts. These parts have consistency even in different batches. The reason being the parts use a digital CAD file to create a prototype. You can easily make changes to the prototype by altering the file.

The 3D Printing Technologies

There is no denying that the emerging rapid prototyping 3D printing has taken the industry to new heights. It is possible to acquire functional prototypes within the house and with a wide range of materials including metals and plastics.

Here are some of the new 3D Rapid prototyping Technologies

ဖျူးငွေစုမော်ဒယ်လ်

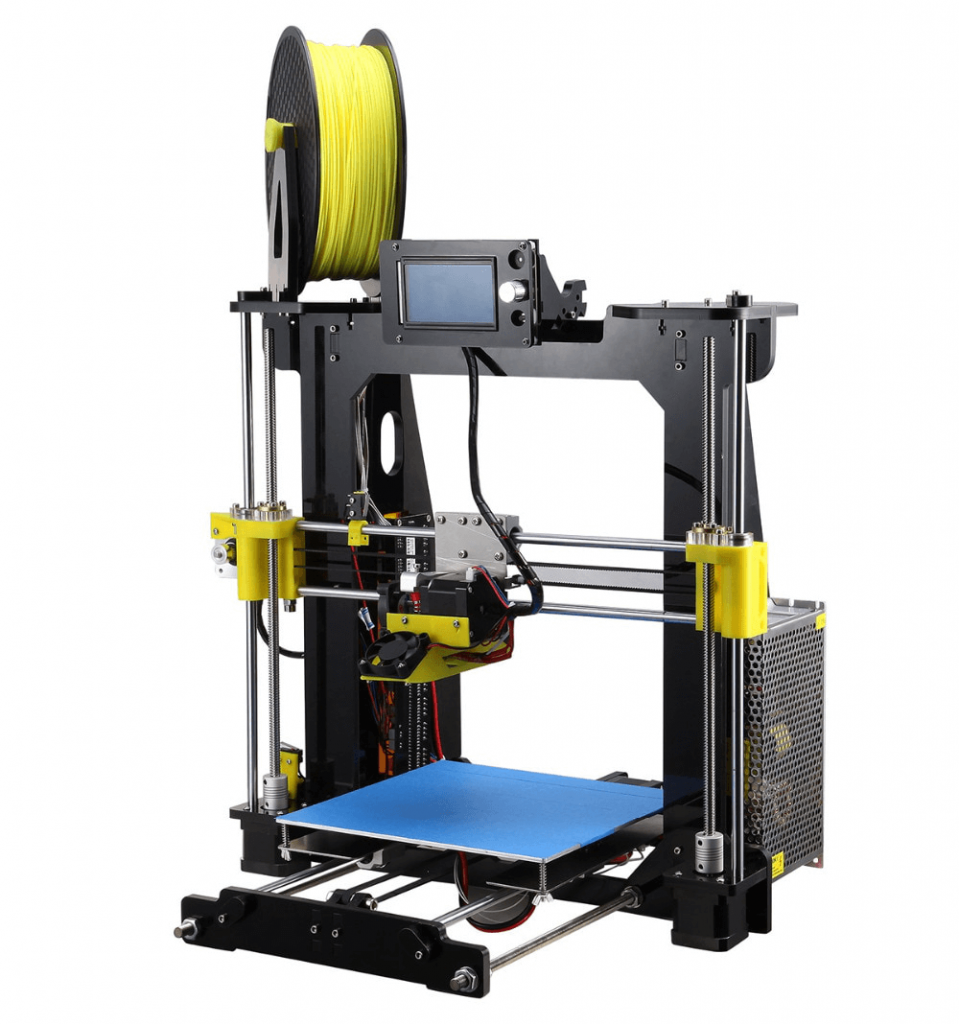

In the 1990s, Stratasys introduced this amazing concept. Fused Deposition Modelling is among the most common 3D printing technologies. It yields highly effective and efficient results. In 2009, several Fused Deposition Modeling patents experienced. The reason being, the companies shifted their focus towards the Fused Deposition Modelling 3D Desktop printers.

They were even able to acquire these printers at a low cost. Thus, making them an excellent choice for companies as well as for hobbyists.

The Working of FDM

In the FDM process uses layer by layer concept to extrude the thermoplastic filaments onto the printing platform. The modern FDM process supports a range of materials. It is possible for ထုတ်လုပ်သူ to select between thermoplastics having different properties.

They can use the durable ABS or elastic TPU. The process also ensures greater flexibility in the production process.

Multi-Material and Full-Color Prototyping

Binder & Material Jetting

Thanks to technological advancement it is now possible to design not only fully functional but also colors and eye-catching prototypes. The concept of multi-material and colorful 3D printing started at the beginning of the 2000s.

This advancement open doors to several exciting opportunities. Prototypes created using this technology were the exact replicas of the final product.

Binder and Material Jetting

These are the two main technologies that allow the possibility of creating prototypes that are exactly like the final product. The multi-color possibilities also offer other advantages. For example, it helps streamline the post-processing finishing process.

Since the client would exactly know how the product would look like, they can make changes to the final finishes like the color or the surface texture. Although both technologies have the same result, there is a difference in their working mechanism.

In material jetting, the process depositions the droplets of photocurable resin, whereas the Binder Jetting fuses plastic powders via a binding agent.

In addition to creating a colorful 3D printed Prototype, Material Jetting also offers the facility of creating parts that require a combination of different material properties. Thus, offering a lot of opportunities to design and develop models that would perform all the functions of the product’s final part.

Metal Prototyping

Some industries including the automotive and aerospace require the one-off functional metal prototypes. They want these prototypes to authenticate the part performance. Thanks to rapid prototyping 3D printing, it is now possible to create prototypes using metal even.

After all, 3D printing does reduce the material waster, offers greater design freedom and it is a toolless production. All these advantages make it an attractive and appealing option to create fully functional and accurate prototypes.

အဆိုပါ sophisticated manufacturers are incorporating newer and better technology to enhance the overall 3D printing techniques. For instance, manufacturers are now using systems use Metal Injection moulding to print metal parts.

They are able to yield more effective results in lesser time and cost, especially when you compare them with 3D printers.

Note: If your objective is to create larger quantities, it is recommended to use the traditional technologies like casting or the CNC machining. 3D printing a better choice for creating models that have complex internal features and you need them in a smaller number.

ထုတ်ယူသွားမည်

Rapid Prototyping 3D Printing သည်စတင်မိတ်ဆက်စဉ်ကတည်းကရှည်လျားသောလမ်းတစ်ခုဖြစ်လာခဲ့သည်။ ယခု၎င်းသည်အလုပ်လုပ်ရန်၊ ခိုင်မာသောနှင့်တိကျသောရှေ့ပြေးပုံစံကိုဖန်တီးရန် ဦး ဆောင်ခြင်းနှင့်အထိရောက်ဆုံးနည်းလမ်းဖြစ်သည်။ အကယ်၍ သင်သည်ယုံကြည်စိတ်ချရသော၊ ပရော်ဖက်ရှင်နယ်နှင့်အတွေ့အကြုံရှိရှေ့ပြေးပုံစံထုတ်လုပ်သူကိုရှာဖွေနေပါက ယနေ့ကျွန်ုပ်တို့ထံကျွန်ုပ်တို့ထံ ဆက်သွယ်၍.

ကျွန်ုပ်တို့သည်သင့်အားလိုအပ်သောသတင်းအချက်အလက်အားလုံးကိုပေးလိမ့်မည်။