7 incríveis fabricantes de protótipos 3D e habilidades rápidas de protótipos 3D

Prototipagem rápida em 3D: o que é, como funciona e para que serve?

O que é fabricante de protótipo 3D e protótipo rápido 3D?

A esta altura, muitas vezes ouvimos sobre o fabricante de protótipos 3D e protótipos rápidos 3D . Muitos são os que o fazem por comércio. Da mesma forma, muitos outros gostariam de abordar esta técnica para melhorar os processos de produção de sua empresa.

But they are still hesitating. The main reason is perhaps, you are not perfectly aware of the topic.

Rapid 3D prototyping: it is a very common name. You might have heard if you are approaching the world of 3D for work. It will have probably happened to you at least once to find yourself in front of this name.

So,

- O que é o fabricante do protótipo 3D e o protótipo rápido 3Din 3D printing?

- Why we need it?

- What are the practical advantages?

Behind this name, it might seem very technical and difficult. But it hides a very useful tool.

How to convert files with 3D rapid prototyping from your pc ?

The English definition of prototype strongly captures its essence: ‘ an early representation of an idea solution ‘. So it is a realistic preview that concretizes an idea. Literally, making prototipagem rápida means making prototypes quickly. But what are they and how are they produced by the PC?

A o fabricante do protótipo 3D e o protótipo rápido 3Dare the initial elements of a production series. Who produces a good has always made a prototype before putting it in real production:

- investing time

- money and

- resources and

- the market

Think of the paper clothes models, the scale furniture models etc.

They are obtained through three-dimensional CAD modelers. It comes from the conversion of 3D files into STL.

Até poucos anos atrás, a produção de um protótipo com métodos tradicionais demorava dias inteiros. Com a prototipagem 3D, o processo de fabricação termina em poucas horas com uma grande redução de custos.

Teste sua ideia: faça o protótipo 3D

Os britânicos dizem “falhe cedo, tenha sucesso mais cedo ”. A mentalidade vencedora é testar as próprias ideias com o objetivo de melhorar sempre, sem medo de falhar.

Você tem uma ideia nova e quer testá-la? Você pode fazer isso de forma rápida e econômica com o protótipo de impressão 3D. Com este sistema, o fabricante do protótipo 3D e o protótipo rápido 3D podem torná-lo realidade. Pode-se esboçar e corrigir antes do lançamento.

Para entender melhor o potencial da prototipagem rápida, vamos pensar sobre a fase de design único. Se no passado era para fazer um objeto, as seguintes coisas eram importantes:

- injection molds and techniques

- accurate thickness and size

- minimum deformation

This technology allows o fabricante do protótipo 3D e o protótipo rápido 3Dto design in 3D freely. Hence, it can happen in a short time. Moreover, it saves a huge cost too. But above all it makes useless real models of the object faithful to the original.

It is also possible to separately manufacture the components. Therefore, we can assemble it later. There is no need to make single piece separately.

In which sectors is 3D prototyping applied?

The potential of 3D prototyping can therefore be hypothesized in various sectors. However, the most promising scenarios concern the areas:

Aerospace: to solve possible design problems quickly and economically;

Automotive: in this competitive sector, being a pioneer in the market can make a difference. From trucks to racing cars through normal cars, prototyping with 3D printing solutions allows you to create prototypes. Furthermore, it performs tests quickly and effectively;

Healthcare: the prototyping of medical devices with 3D printing allows you to test the components. It is possible at the same time they are produced. From the additive manufacturing of functional parts to the creation of models for tests, etc.

How 3D prototyping works: comparing technologies

If you find yourself reading this page, it is because, in all likelihood, you are curious to find out more. So let’s see better how o fabricante do protótipo 3D e o protótipo rápido 3Dworks.

The first major distinction that we can now make is between additive, subtraction and fusion. All three basically allow you to make an object in full scale.

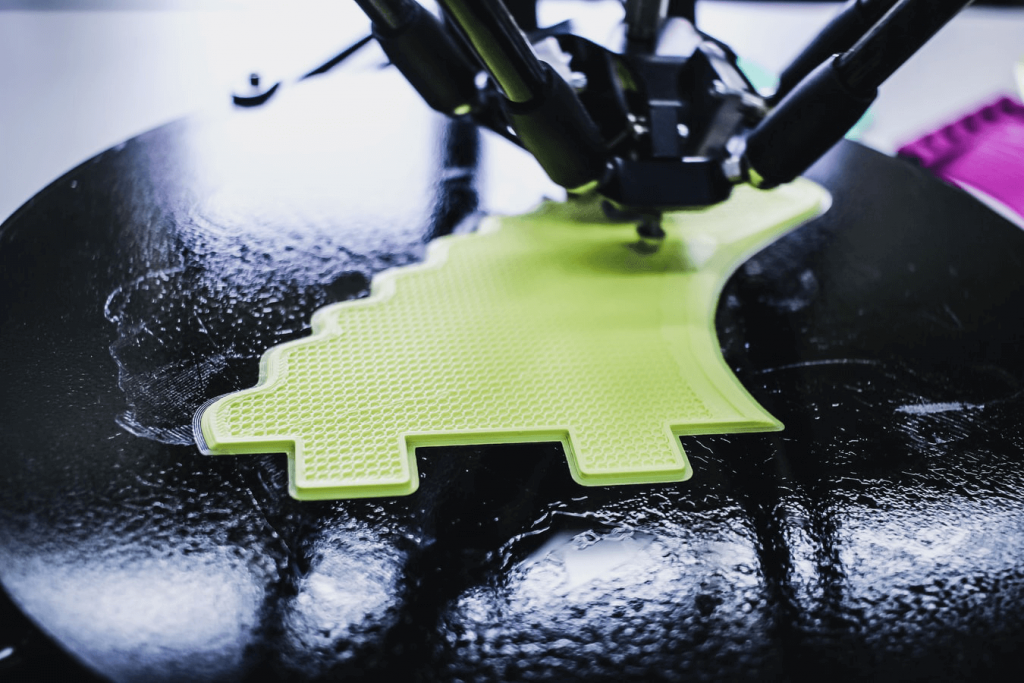

Generally, the most common is the first one. Through this 3D printing, obtains the prototype. Within the additive manufacturing different techniques are distinguished. These are:

- FDM

- SLS

- SLA

- MJP

- CJP and SCP.

Let’s analyze the differences more precisely.

o fabricante do protótipo 3D e o protótipo rápido 3DAdditive prototyping techniques

More specifically, they fall into this category:

Fused deposition modeling: also suitable for very light materials such as ABS and PLA. Fused Deposition Modeling was born in the late 80s.

Stereo lithography: SLA is the first rapid prototyping technique. It is based on the polymerization of a liquid resin using lasers. This system allows the production of even rather complex and delicate pieces.

Selective laser sintering: Selective Laser Sintering uses a laser that melts different powders. Later, it spread them on layers. In this way a more precise and resistant prototype is obtained. But the finishing tends to be less precise.

Poly Jet: Technology applicable to very different materials. It therefore allows o fabricante de protótipos 3D e protótipos rápidos 3D to obtain prototypes of particular shapes.

Poly Jet: Technology applicable to very different materials. It therefore allows o fabricante de protótipos 3D e protótipos rápidos 3D to obtain prototypes of particular shapes.

The limit is that prototypes tend to be less resistant. Thanks to its high precision and speed of realization.

3D Print: technology preferred by expert makers in digital fabrication. It is very fast to print and very easy to apply in the creation of prototypes.

Implemented in 1993, the 3D Print technique is based on heads for inkjet printing. It release a liquid compound based on glue on a material composed of:

- Starch

- plaster or

- Ceramic powder.

The objects thus obtained are characterized by bright colors. But, on the other hand, they appear to be less resistant and rough.

Multi Jet Printing: It appeared in 2006. This technique is centrally based on the melting and deposition of layers. Subsequently, it is for the materials resistant to high temperatures. The result is a highly detailed finish.

Subtraction and fusion prototyping techniques

Em segundo lugar, encontramos a produção subtrativa que, em vez disso, segue o caminho oposto. o fabricante de protótipos 3D e protótipos rápidos 3D partem de um bloco de material exclusivo. Ele remove gradualmente o supérfluo até obter o produto acabado.

Também neste caso as tecnologias podem ser diferentes.

- Moagem

- girando e

- perfuração são as mais conhecidas

Por último, a fusão cria protótipos a partir de um modelo. Após a impressão 3D, um molde de borracha de silicone é obtido. Ele é preenchido com o material final. Essa também pode ser uma técnica útil. No entanto, por exigir várias etapas, a fusão é mais adequada para grandes lotes.

Melhores projetos com o fabricante do protótipo 3D e o protótipo rápido 3D3D

Não importa o que você projete, você quase nunca obtém o melhor produto imediatamente

A prototipagem é essencial para eliminar erros de projeto. Isso só pode surgir após o início da produção. Um o fabricante do protótipo 3D e o protótipo rápido 3D representam uma ferramenta muito eficaz para ações de marketing.

Também melhora a compreensão do projeto dentro da equipe. Além disso, reduz o risco de erro.

Prototipagem rápida com impressora 3D

Mais revisões, em menos tempo, com custos reduzidos

Identificar e resolver problemas no início do ciclo de design é essencial para evitar desperdício e retrabalho. A prototipagem rápida com impressão 3D permite aos designers e engenheiros industriais mais revisões em menos tempo. Ele mantém testes detalhados, enquanto reduz o tempo de lançamento no mercado.

Modelos físicos transmitem ideias para:

- colaboradores

- clientes e

- distribuidores imediatamente e claramente

O o fabricante do protótipo 3D e o protótipo rápido 3Dfacilitates the communication of the concept. It allows to obtain detailed feedback. It is essential for the success of the product.

Simplify the design process with o fabricante do protótipo 3D e o protótipo rápido 3D3D

All projects are born from an idea. Develop it without wasting time.

The design process is by its nature an adventure into the unknown. It will always result in frustrating questions.

Prototyping is essential to eliminate design errors. It can only emerge after production has started. A realistic prototype represents a very effective tool for marketing actions.

It also improves understanding of the project within the team. Moreover, it reduces the risk of error.

- Functional tests

- aesthetic and

- dimensional checks

These are the best way to evaluate what works and what doesn’t. Rapid prototyping with 3D printing offers the flexibility to make this process simple and convenient.

Design of machines with metal 3D printing: applications and advantages

In the design of machines we can identify some key phases:

- development

- industrialization

- manufacture and

- maintenance

It is critical to ensure that machines operate efficiently. It produces consistent results. Subsequently, it has easy repairing module. In this context, o fabricante do protótipo 3D e o protótipo rápido 3Dbrings numerous advantages to designers and builders.

Machine design: o fabricante do protótipo 3D e o protótipo rápido 3Dcritical factors

- For simplicity

- speed and

- above all

- Cost

Os projetistas de máquinas se esforçam para usar o maior número possível de componentes padrão. No entanto, algumas peças precisam ser feitas sob medida. E isso implica um esforço para reduzir custos e tempos de fabricação .

As peças personalizadas normalmente têm capacidade de usinagem CNC devido ao pequeno volume. Um processo que pode ser caro e demorado depende da complexidade da peça.

Além disso, os o fabricante do protótipo 3D e o protótipo rápido 3D que projetam e constroem máquinas enfrentam problemas. Eles estão relacionados ao equipamento. Isso já está em operação.

Algumas peças que compõem a máquina se desgastam ou quebram. As empresas devem ser capazes de produzir peças de reposição rapidamente para restaurar a funcionalidade da máquina. Ele mantém os custos das peças baixos e evita os custos de armazenamento tanto quanto possível.

How 3D printing rapid prototype simplifies the design of machines and their construction?

The additive manufacturing greatly simplifies the process of creating custom parts. It is not based on equipment or fasteners. 3D printing often allows users to print parts faster and at lower costs than traditional processing.

Metal 3D printing technology also opens doors to parts with greater geometric complexity. These complex parts may be more suitable for the application. They induce greater efficiency. But they are generally very difficult.

The ability to build even complex parts more easily allows o fabricante de protótipos 3D e protótipos rápidos 3D to consolidate assemblies. It combines multiple parts into a smaller number of multifunctional assemblies.

It will result in simplified production and increased efficiency. Designing in 3D for Additive Manufacturing allows you to take advantage offered by additive technology.

A 3d prototype manufacturer also helps to simplify the production of spare parts. It enables companies to print exactly the part they need. When and where they need it? It significantly reduces both downtime that inventory costs.

o fabricante do protótipo 3D e o protótipo rápido 3DMachine design

The contexts in which the use of 3D printing in machine design offers significant advantages are manifold.

Production methods such as:

- Casting

- forging and

- injection molding of metals

They are ideal for mass production. They are not very convenient for prototype construction. It is due to the high costs and long delivery times. 3D printed parts can have the same quality as those obtained with the mass production methods.

But the use of tools is not necessary, with a significant saving of time and money. Since 3D printing eliminates the need for tools, the part can be easily printed.

o fabricante de protótipos 3D e protótipos rápidos 3D offer a growing autonomy of work. Prints can also be performed during the night.

Using the 3D metal printing of Desktop Metal Studio System, this part can be quickly prototyped. Whenever you need without performing the merger, it greatly reduces the cost of the part.

Moreover, it impact the manufacturing lead time.

Atualmente, o fabricante de protótipos 3D e protótipos rápidos 3D embrace the entire world production system. It involves:

- Artesãos

- Arquitetos

- Planejadores

- Designers

- engenheiros e industriais

Mas não posso te dizer que em alguns anos haverá um protótipo 3D em cada mesa. Porque isso significaria tirar sarro de você.