SỰ KHÁC BIỆT GIỮA GIA CÔNG CNC VÀ IN 3D

Khi công nghệ tiến bộ và cách mạng hóa kỹ thuật và máy móc, bạn muốn biết mình đang sử dụng thiết bị tốt nhất và dẫn dắt doanh nghiệp của bạn về phía trước. Một số tiến bộ này là trong gia công điều khiển số máy tính (CNC) và in 3D. Cả hai đều làm việc với các vật liệu khác nhau. Nhưng cái nào là tốt nhất cho nhu cầu của bạn?

CNC machining and 3D printing have similarities and differences, and each has unique benefits. They have varying circumstances where you would want to use them regarding cost and availability. Breaking down each manufacturing style will help you pick the best method for you and your business.

Their main differences occur in production, waste, scale, material availability and size of the parts.

SIMILARITIES BETWEEN CNC AND ADDITIVE MANUFACTURING (3D PRINTING)

CNC machining and additive manufacturing are both computer-controlled solutions to making products out of a given material. They’re both machines at the forefront of building technology safely and efficiently.

As machinists and engineers want to build a prototype, a part or a custom product, they can turn to one of these machines to do the job for them. As long as the machines have the design, you don’t have to worry about human error because the machines are automated. While this doesn’t mean issues don’t arise, there’s more consistency with production and less chance of injury.

There is some overlap with these two manufacturing methods. Some CNC machines can use STL and OBJ files, which 3D printers also accept.

CNC machinery is older than 3D printing and still has a stronger foothold in manufacturing. The form started in the 1940s and had molded to fit into the industry up to the present. 3D printing came along in 1986. It’s still relatively new and evolving to be more accessible and versatile. 3D printing can help in some areas of prototyping, but it’s not a replacement tool for CNC machining.

They’re not so much alternatives to the other as they are both aspects of the manufacturing world. They meet different demands and handle different materials and markets. CNC machines and 3D printing both have unique capabilities and constraints that suit them for specific jobs. As they fit their niches in the market, you’ll want to compare it to whatever industry you’re in.

DIFFERENCES BETWEEN CNC MACHINING AND 3D PRINTING

From their building methods to what applications they can handle, CNC machining and 3D printing offer creative solutions in vastly different ways. Finding out their differences and strengths will help you find which one is right for you and your business.

3D printers are typically more efficient than traditional manufacturing. The printer uses the materials that make up the item it’s creating, whereas traditional manufacturing methods such as CNC Machining require more materials for the mold to work. On average, 3D printers produce less waste than traditional manufacturing methods.

However, when production is large-scale, traditional manufacturing methods have a distinct advantage. Assembly lines are faster than a 3D printer in mass production because printers build layer by layer. In the hours that it could take to 3D print a product, an assembly line could have mass-produced hundreds of the same product.

Additionally, 3D printers can only use the area of the printing bed for making parts. Large-scale parts might not fit in that space. While the parts can be broken down into smaller pieces 3D printers can build, that might not be cost-effective and will take time. Traditional manufacturing has the advantage of the assembly line’s labor and will be able to produce items on a larger scale. Future 3D printers could be able to build larger items, but not on the level of what CNC machines offer with regard to quality and quantity.

3D printers can manipulate different materials such as plastics, metals and polymers. However:

- Not all 3D printers can use these materials. It takes separate machines for each material.

- 3D printers cannot work with every material that traditional manufacturers use due to high melting points.

- Some projects might not be able to consider using 3D printers if they require specific materials that are incompatible with the printers.

Here is the bottom line — 3D printing won’t replace traditional manufacturing because of its disadvantages in mass-produced items.

3D Printing vs. Traditional Manufacturing

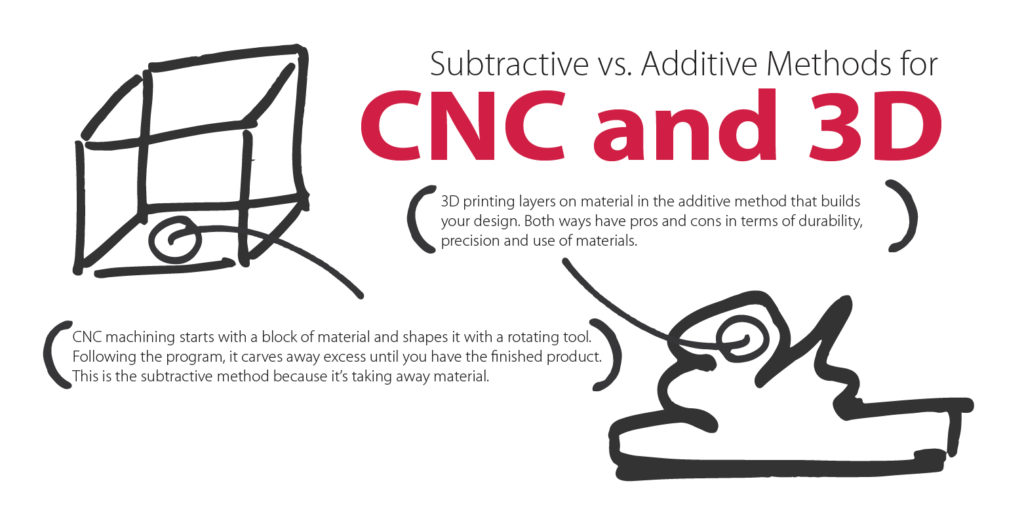

CNC machining starts with a block of material and shapes it with a rotating tool. Following the program, it carves away excess until you have the finished product. This is the subtractive method because it’s taking away material.

3D printing layers on material in the additive method that builds your design. Both ways have pros and cons in terms of durability, precision and use of materials.

Material Usage for CNC and 3D

CNC machining works with a variety of materials. They can use:

- Metal alloys

- Woods

- Acrylic

- Modeling foam

- Nhựa nhiệt dẻo

- Machining wax

CNC machines have heating systems that can manage heavy materials. These materials are used to build substantial parts for engines, aircraft and other machines. They need to be exact, dependable and durable. The cutting tools for the design might have to switch, but most tools are standardized to fit any CNC machine.

3D printing doesn’t have this variety, using materials like plastics or resins. They can’t produce items strong enough to withstand intense environments like airplanes or other machinery. Also, 3D printers can’t switch between materials. Certain 3D printers are for specific kinds of material.

3D and CNC Precision of Production

CNC machining is more precise and consistent than 3D printing because they have a higher tolerance for heat. 3D printers end up with distorted products when there’s too much heat. They can offer precision but cannot remain consistent. 3D printers are often regarded as more user-friendly than CNC machines, but when they malfunction, someone has to troubleshoot them because the fault means production of unusable products.

CNC and 3D Speed of Production

CNC is a faster solution than 3D printing. Automated CNC machines can work around the clock as long as they’re properly maintained. A project that could take CNC machining an hour would equate to a 3D printer taking hours to get the final product because it has to build the product layer by layer. A 3D printer’s pace might have to slow down during the process to get the design right. Different 3D printers could also be programmed with specific speeds that you can’t alter. It depends on the machine you use.

Các sản phẩm in 3D cũng yêu cầu công việc sau khi chúng được chế tạo. Các sản phẩm cần được rửa sạch, đánh bóng và niêm phong trước khi mọi người có thể sử dụng sản phẩm. Điều này có thể kéo dài quá trình thử nghiệm nguyên mẫu trong một khoảng thời gian dài hơn với rất nhiều thời gian chờ đợi. Máy in 3D cũng phổ biến cho các mặt hàng nhỏ hơn, sản xuất theo yêu cầu. Nhưng nếu bạn phải đợi hàng dựng xong mà vẫn phải thực hiện nhiều công đoạn hậu in thì bạn mất rất nhiều thời gian mới có thể chuyển sản phẩm được.

Tính linh hoạt của Máy móc cho CNC so với 3D

Máy CNC có thể sản xuất đồ đạc, công cụ và các bộ phận được thiết kế riêng. Họ có một loạt các cài đặt chất lượng để bạn có thể tạo một mẫu thử nghiệm có thiết kế thô hơn ở một số khu vực và hoàn hảo ở một số khu vực khác để bạn có thể kiểm tra phần đó.

When testing prototypes for a project, a CNC machine could quickly build a design so the developers can test it. 3D printers don’t have these kinds of options. It will slowly shape the design as it was programmed. Accuracy is key when constructing a final product, but when time is a constraint and you want to test some prototypes, 3D printers can slow down you and your project. Designs made for a CNC machine usually can’t be substituted with a 3D printer because the products are voluminous and it would take hours for a 3D printer to finish them.

Noise and Mess Produced by CNC and 3D

Những khác biệt này liên quan đến các phương pháp trừ và cộng. Gia công CNC ồn ào và lộn xộn hơn nhiều so với in 3D vì nó sử dụng một công cụ để cắt vật liệu. Điều này tạo ra tiếng ồn và rất nhiều kim loại phế liệu hoặc dăm gỗ. Máy CNC gây ra nhiều rung động, vì vậy chúng cần phải ở trong một không gian mà chúng sẽ không làm phiền ai. In 3D chỉ sử dụng vật liệu mà nó cần cho sản phẩm. Có rất ít hoặc không lãng phí và máy in không rung như máy CNC.

Ứng dụng cho CNC và 3D

Gia công CNC có thể sản xuất các sản phẩm lớn hơn và có thể xử lý chịu nhiệt. In 3D có nhiều danh mục thích hợp hơn, chẳng hạn như in thực phẩm hoặc làm việc trong không gian.

Gia công CNC so với In 3D

According to World Finance, 3D printing is not a solution that can replace CNC machining. 3D printing is a part of the manufacturing world, but it’s not the invention that’s going to change the market as everyone knows it.

3D printers can improve certain aspects of manufacturing but cannot handle the whole market, as CNC machining still works better in many situations. CNC machining still offers better quality than expensive 3D printers.

On a smaller production scale, 3D printers have an edge in saving businesses money from buying expensive molds. They also offer an insight to the product’s shape and aesthetic. But as production increases and time factors in, they don’t hold up as well as CNC machines.

BENEFITS OF CNC MACHINING OVER 3D PRINTING

CNC machining fits with mass production. It can create many products in a shorter period, where 3D printing would take hours to create one product. That’s just one advantage of CNC. Let’s take a look at some others.

Prototyping Becomes Easier

CNC machines are better for prototypes that can withstand structural tests because they carve the design from the material. They can also build prototypes out of the exact material that will be used to make the final product.

Structural tests and alterations will be more accurate because they use the same material. This could speed up the production process because the changes will be to the design and not the material. 3D printers don’t fabricate prototypes with the structural strength, so they can’t conduct physical tests.

Prototype Integrity Improves

CNC machines don’t heat the material and reform it. The material stays stronger and has a better structural integrity than 3D printers, which have to heat the material to build the intended product. 3D printers might also have to add foreign materials to the mixture to be able to make the prototype, which CNC machines don’t need.

Surface Finish Advantage

CNC machines provide better surface finish than 3D printing because the materials don’t deform during the process. The rigid material and cutting action keeps the product together and has fewer chances for mistakes or deformations to occur. 3D printing has poorer surface finish. The material bends, warps or distorts because the material is layered heated plastic.

Tolerance Levels Rise

CNC machines work with higher precision, so the parts have a better tolerance than 3D printers. Because of tolerance level, prototypes that have shafts or connect to other parts will be higher quality and will more likely fit with other components.

Price and Volume Don’t Dictate Price

3D printing costs depend on the volume of needed materials. Final product volume doesn’t dictate the price for CNC machines. 3D printing wouldn’t be cost-effective with larger orders, and this is the situation where CNC machines thrive.

Quality in Favor of CNC

Larger layers from a 3D printer are faster but not as high-quality as smaller layers. If you need a prototype, you have a choice to get it fast but of slightly less quality, or wait longer for the prototype with the best quality the printer can provide. CNC machines have the option for you to choose resolutions for your item. They can offer varying qualities in a short amount of time, making them ideal for quick builds and immediate results for testing.

Keeping Costs Down

If you have the option of choosing which manufacturing method to use for your product, CNC machining is usually cheaper than 3D printing.

Contact Kaito mould Works, Inc., for Your CNC Machining Needs

Gia công CNC có thể xây dựng các bộ phận bạn cần cho doanh nghiệp của mình. Các chuyên gia gia công chuyên nghiệp của chúng tôi tại Kaito Mold Works, Inc., sẽ cung cấp những tác phẩm xuất sắc giúp bạn đạt được mục tiêu của mình. Chúng tôi mong muốn giúp bạn có được phần chính xác cho dự án của mình.

Kaito Mold Works, Inc., cung cấp các dịch vụ chế tạo máy tùy chỉnh, máy linh kiện chính xác và thiết kế ngược các bộ phận để cung cấp cho bạn sản phẩm bạn cần ngay lập tức. Chúng tôi cung cấp các giải pháp gia công CNC đặc biệt cho các nhà sản xuất trong nhiều ngành công nghiệp. Kỹ năng chuyên môn hóa và sự tận tâm trong công việc của chúng tôi sẽ giúp bạn và doanh nghiệp của bạn luôn dẫn đầu trong ngành. Chúng tôi có các giải pháp bạn cần. Hãy liên lạc với chúng tôi ngay hôm nay.

Nếu chúng tôi có thể giúp bạn với dự án của bạn, vui lòng gọi cho chúng tôi theo số 0086-769-82821468 hoặc email tới sales@kaitomould.com.