تصميم الشركة المصنعة لقوالب الحقن ونصائح العملية

آليات تصنيع قوالب الحقن

تشارك الصناعات في جميع أنحاء العالم في تصنيع قوالب الحقن لعمليات الإنتاج الضخم. بعد كل شيء ، القولبة بالحقن هي عملية تصنيع موثوقة وفعالة. إنه ممتاز لإنتاج الأجزاء من البلاستيك بالحرارة والمواد البلاستيكية الحرارية.

There has been an increase of 0.9% in the injection moulding industry since 2014. It seems that numbers are on the increase. The reason being, this manufacturing process can produce hundreds even millions of parts without slight variation.

A consumer can enjoy reliability and consistency even in mass production. Injection moulding has become an imperative part of the manufacturing process. Therefore, we are going to provide you with the basics of the injection moulding process.

What is the Injection Moulding Process?

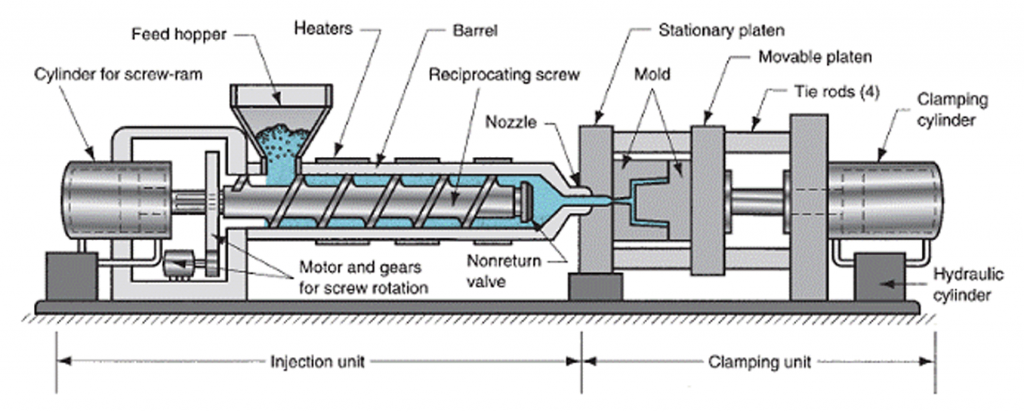

A manufacturing process uses a special technique to produce the part from both thermosetting plastic and thermoplastic materials. The process starts with the design of the product or parts. Industry engineers or designers are responsible for product designing.

Once the design finishes, next come the formation of molds. Mold maker is responsible for making accurate molds. They can use either aluminum or steel to develop molds. They also use precision machines to ensure the exact shape of the moulds.

After completing the molds, it is time to place the material into the molds. The machine places the material into a heated barrel. It then mixes the material thoroughly. Later, it forces the heated material into a mold cavity.

The material stays in the cavity for as long as it takes to cool it down. Once the material hardens to the designed configuration, it is removed from the mold cavity. Injection molding offers diversity in terms of manufacturing. It is possible to manufacture small parts as well as the entire body of a car.

التاريخ

Alexander Parkers was the mastermind behind inventing first fabricated plastic. In 1862, during an International Exhibition in London, Alexander demonstrated its material. The named the material “Parkesine”.

Parkesine mainly compromised of cellulose was able to take on any shape. After heating and melting the material, it was possible to mould it in any desired shape. However, it did have some side effects. The material was highly flammable, expensive and prone to crack.

Later in 1872, Alexander and his brother Isaiah came up with an injection moulding machine. The machine was not as sophisticated as we see today.

It had a huge hypodermic need and to inject the plastic it used a plunger. The material first passed through heated cylinders before they reach the mold cavity. It did take some time for the industry to progress. Initially, it produced online hair combs, buttons and collar stays.

However, in the 1940s, the industry rapidly expanded. World War II led to the demand for mass production of products at an extremely low price. Six years later, James Watson Hendry, an American inventor, introduced the screw injection machine.

The machine was an advancement of what Alexander had designed. It was able to better control the speed of injection. The product was also finer. In addition, the machine permitted the mixing of materials. Thus, allowing adding colors to the material.

The mixing made it possible to add the recycled plastic to the virgin material. Today, most injection moulding die manufacturer use screw injection machines. However, these machines are way advance than their ancestors.

The plastic injection industry has made tremendous progress over the years. Thus, we now can enjoy sophisticated machines. From those simple machines, we know have a wide variety of sophisticated injection moulding machines. These machines can produce almost anything.

Different Types of Injection Moulding Process

The basics of the injection moulding process remain the same in every type. They heat the plastic granules until they melt. The melted material is inserted into the mould using high pressure and nozzles. Finally, you wait for the material to cool down and harden in the required shape. Then remove them from the mould.

فيما يلي بعض الأنواع الشائعة لعملية قولبة الحقن :

- النفخ بالحقن

- صب حقن الغاز

- صب حقن رد الفعل

- صب حقن متعدد المحطات

- صب حقن متعدد المكونات

- صب حقن مزدوج

- صب حقن ثلاثي من بين أمور أخرى

خصائص العملية

أدناه ، قمنا بتسليط الضوء على الخصائص الرئيسية للعملية.

- لإدخال المادة المنصهرة (أي نوع من البلاستيك) في تجويف القالب ، يتم استخدام مكبس من النوع اللولبي أو كبش.

- النتيجة t هي شكل مفتوح النهاية وصلب. الشكل حسب محيط القالب.

- يمكن أن تستخدم العملية إما مواد بالحرارة أو مواد لدن بالحرارة.

- وهي مسؤولة عن إنشاء علامات البوابة ، والذرب ، وخط الفراق.

- ستصادف علامات دبوس القاذف ، لأنها موجودة بشكل شائع.

التطبيقات

Today, the injection-moulding machine can create a wide variety of things. For instance, they are used for producing automotive dashboards, bottle caps, packaging, and spools. They can also produce pocket combs, buttons, and several other plastic products.

Today, automobile manufacturers are a fan of injection moulding manufacturing. It is perhaps one of the most common methods to create car spare parts. In addition, industries around the world use this technique to create different types of parts.

The injection moulding process is excellent for mass production with zero tolerance to error. They can replicate the same product for thousand times without a slight error. It is also possible to use a wide range of materials.

The process is cost-efficient. It has minimal scrap losses and low labor costs. Usually, the finished products require none to minimal finishing after moulding. Nonetheless, the upfront cost of injection moulding die manufacture process is high. The machine is expensive and setting it up requires additional cost.

بالقطع

There are two main methods of creating a mould. Frist is the Standard Machine technique and the second is EDM. Both of these techniques offer great results. However, there are some differences in terms of functionality and usage.

Standard Machining

It is the historical method of creating the injection molds. Nonetheless, technological developments resulted in sophisticated technologies such as CNC machines. The CNC machining was highly efficient. They become an integral part of the injection moulding industry.

كانوا قادرين على إنشاء قوالب معقدة في وقت أقل. على الرغم من إنشائها في أقل وقت ممكن ، إلا أن هذه القوالب توفر الدقة.

آلة التفريغ الكهربائي (EDM)

اليوم ، أصبحت صناعة القولبة من محبي عملية تصنيع التفريغ الكهربائي. غالبًا ما يشير الناس إلى EDM باسم عملية Spark Erosion. إنه مثالي لتصميم القوالب المعقدة. بالإضافة إلى ذلك ، فهي تقدم قوالب مسبقة الصلابة. وبالتالي ، ليست هناك حاجة للمعالجة الحرارية.

لتليين القالب ، ستحتاج الشركة المصنعة إلى التلدين. من أجل إجراء تغييرات على القوالب الصلبة ، فإن عمليات الحفر التقليدية ستدخل حيز التنفيذ.

كلفة

هناك عدة عوامل تساهم في تكلفة القوالب. تتضمن بعض هذه العوامل حجم الجزء والتجاويف وطول العمر المتوقع للأداة. بالإضافة إلى ذلك ، يحتاج مصنع قوالب الحقن إلى التركيز على تعقيد القطع وتشطيبات الأسطح.

Although, the initial cost is high, however, the cost decreases due to mass production.

Advantages of Injection Moulding Die Manufacturer

- It is possible to do mass production of parts with good surface finish.

- Manufacturers can use metallic along with non-metallic moulds to create parts.

- The process is economical to produce small parts and intricate shapes.

- Injection moulding has the ability to uphold close dimensional tolerance.

- It is possible to use and reground minimum sprue, gate and runner.

- It has a low labor cost per unit.

Limitation of Injection Moulding Process

- It requires high power to operate

- The maintenance cost is high.

- Moulding Machines are expensive.

- High tool cost.

Takeaway

توفر الشركة المصنعة لقوالب الحقن بالراحة والسهولة. من الممكن تصميم الأجزاء المعقدة وتطويرها في أقل وقت ممكن وميزانية محدودة. تضمن عمليات التشكيل الحديثة الموثوقية والكفاءة.

تقدم الشركات المصنعة الحديثة وذات المهارة مثل سيقوم خدمات صب متميزة. يستخدمون أحدث التقنيات والتقنيات الحديثة لإنتاج أجزاء عالية الجودة. لذلك ، يجب عليك التواصل معهم. يمكنك التواصل بسهولة مع موظفي خدمة العملاء المتعلمين على الرقم 0086-768-82821468. سيقومون بحل جميع مشاكلك واستفساراتك.