Warum betonen Hersteller von kundenspezifischen Kunststoffformen den Formenherstellungsprozess?

Wie stellen kundenspezifische Kunststoffformhersteller Formen her?

Bei der Herstellung Ihrer kundenspezifischen Teile ist die Form das Wichtigste. Wenn Sie eine fehlerfreie Form haben, können Sie fehlerfreie Teile und Komponenten haben. Daher müssen Sie die Grundlagen der Herstellung von Formen für kundenspezifische Kunststoffformen verstehen.

Wenn Sie hochvolumige kundenspezifische Teile herstellen möchten, . Es gibt verschiedene Arten des Spritzgießens . Wählen Sie diejenige, die Ihrem Bedürfnis nach Perfektion entspricht.

Bevor Sie jedoch mit einem Projekt beginnen, müssen Sie Faktoren wie die Größe der Teile, die Herstellung dieser Teile, das Werkzeugbudget, das verwendete Material oder die Teilemenge berücksichtigen. Es wäre auch großartig, etwas über die grundlegenden Formenbaumaschinen zu lernen.

In diesem Blog-Beitrag werden wir all diese Aspekte behandeln. Lassen Sie uns also ohne weitere Verzögerung loslegen!

Kundenspezifische Kunststoffform - Formenbau

Teilemenge bestimmen

Wenn Sie kundenspezifische Kunststoffprodukte mit hohem Volumen anstreben, sollten Sie mindestens 100.000 Teile oder mehr einplanen. Dies ist normalerweise die Mindestmenge, die von den meisten kundenspezifischen Kunststoffformherstellern benötigt wird.

Daher ist es wichtig, Ihre Produktpläne zu berücksichtigen und zu prüfen, ob Sie diese Art von Teile- oder Komponentennummer benötigen.

Erstellen und Bewerten Ihres Werkzeugbudgets

Ein weiterer wichtiger Faktor, der berücksichtigt werden muss, ist Ihr Budget für Werkzeuge. Dies umfasst Ihr Design und die Erstellung des Tools. Stellen Sie sicher, dass Sie alle Aspekte untersuchen, bevor Sie mit Ihrem Projekt fortfahren.

Die Komplexität Ihrer Form wirkt sich direkt auf die Kosten aus. Eine gute Idee ist es also, die Komplexität der Formen zu reduzieren. Versuchen Sie es so einfach wie möglich zu machen, um die Kosten niedrig zu halten. Konzentrieren Sie sich auch auf andere Aspekte, mit denen Sie die Kosten senken können.

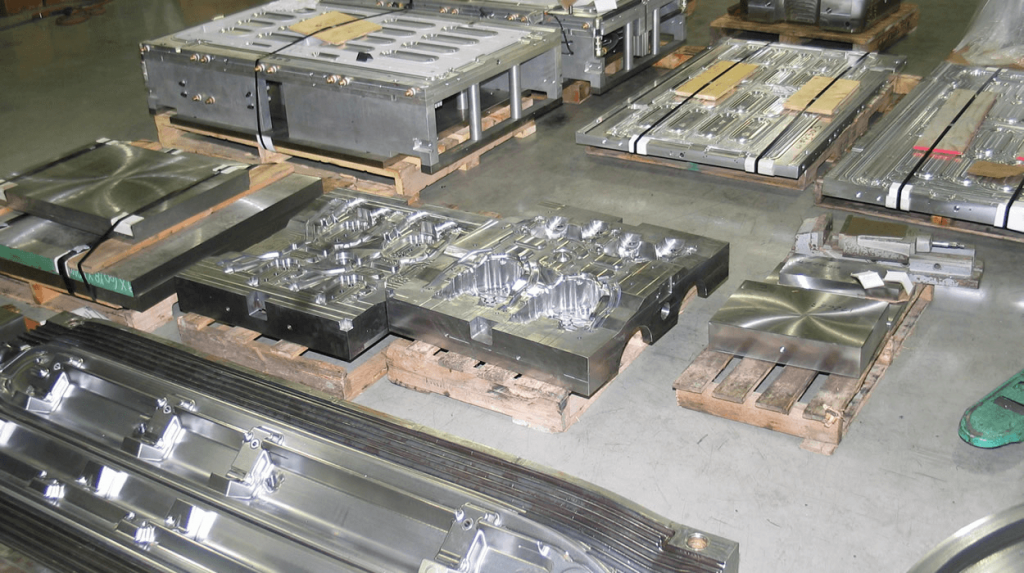

Also, focus on the tools that you would use for the creation of molds. Below, we have listed some common and popular tools.

Standard CNC Machining

The orthodox form of the CNC machining requires milling, manual use of lathes, and drill presses. However, with technological advancement, the CNC machining has become the most dominant means of creating complex and high-level molds.

While it is using the standard machining methods, it still can produce complex molds. With CNC, they use computers to control the operation and movement of the lathers, mills, and other several cutting machines.

However, modern CNC machining systems have become sophisticated and advance. The current systems are fully automated in terms of mold designing and manufacturing processes.

It now uses a computer-aided manufacturing software (CAM) to define the mechanical dimensions of the mold. The instructions are translated into specific commands using a post-processor software. This is imperative for every machine that creates a mold.

The resulting command is loaded into the CNC machine for the manufacturing process to start.

Electrical Discharge Machining

Another famous machine for making molds is electrical discharge machining (EDM). This process uses an electrode to obtain the desired shape of the mold. The shape is fabricated out of copper or graphite. Next, comes the mounting in the EDM machine.

Later, it is positioned over the workpiece. It is submerged in a dielectric fluid. The workpiece comes into contact with the electrode. Thus, you would be using a controlled electrical source to disperse the metal in different areas that are opposite to the electrode.

The workpiece never comes in contact with the electrode. There is always a gap between the electrode and the workpiece. The gap is a few thousandths of an inch. Although, the EDM process is slower when it comes to removing the metal from the mold especially when you compare it with the CNC machining.

However, with EDM the Hersteller von kundenspezifischen Kunststoffformen are able to acquire the most difficult shapes. Something they are not able to achieve via the conventional CNC machining. Another great thing about the EDM process is that it provides the facility of working with pre-hardened molds.

Thus, it eliminates the requirement of additional heat-treating methods. What more is that the finial resulting of EDM finishes tends to be the final finish. You do not recover additional working on the polishing of the mold cavity.

Mold Design

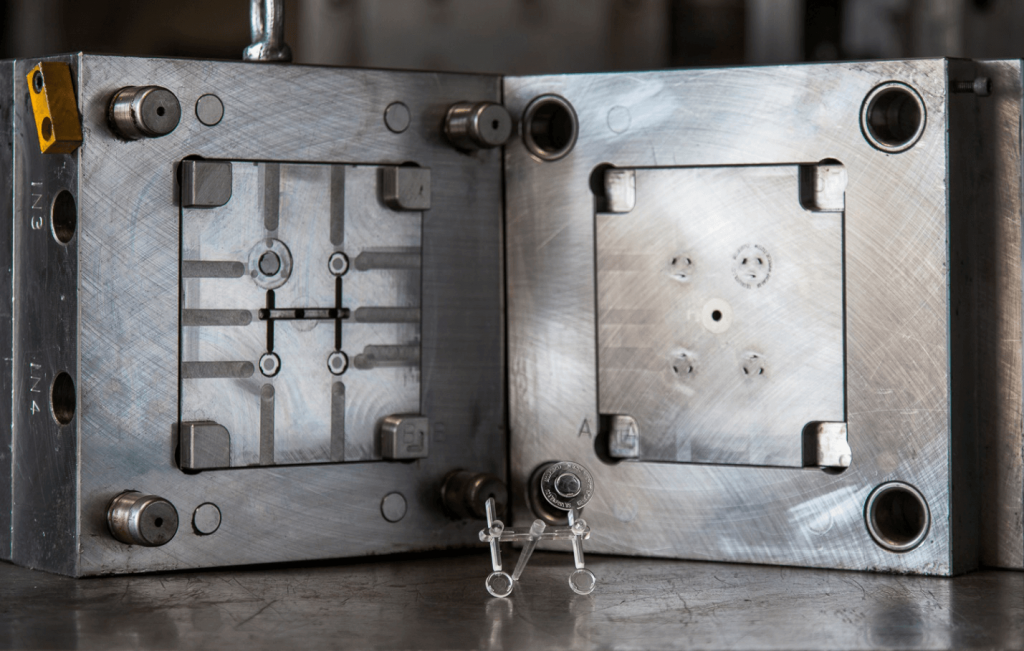

There are two main components of the plastic injection molds, first is the cavity half of the mold and the second is the ejector half of the mold. It is important for the mold halves to work in conjunction. Below, is how they work together.

The plastic resin from the molding machine would enter through the gate or the sprue on the first half of the mould.

Injection barrel’s nozzles have a sprue tightly sealed against it. This ensures that the molten plastic tends to flow seamlessly from the barrel to the cavity or the mold.

The molten plastic is passed through different channels – runners. The sprue bushing is responsible for the direction of the channels. These channels have access to the faces of both the first and the second half of the mold.

The molten plastic enters a specialized gate via the runners. Thus, allowing the molten plastic to enter the cavity in order to shape the requested parts.

While designing the mold, it is important to remember that the molded parts reliably remain in the second half of the mold when it opens.

The manufacturers take out the sprue and the runners from the first half of the mold. Thus, allowing the molded part to fall freely once, it is ejected from the second half to the mold.

A single plastic injection mold has just one cavity. This means it has the ability to produce only one part at one time. It is possible for the molds to have multiple cavities. Ensuring high-production molds. For example, a bottle cap molds can have 100 plus cavities. Thus, it can produce multiple bottle caps at one given time.

Size Considerations and Design Production

It is not possible to create all parts using the injection moulding process. Good custom plastic mold manufacturers would evaluate the design before approving it. They would work on the design, make changes if required to ensure that a structurally sound part is produced.

Also, the optimization of the design would help down cut the cost. The designers would make all the required changes to ensure that the parts of working and accurate. If you need smaller size parts, we recommend that you use the injection molding process.

In this case, make sure that the design is not bigger than 10 x 10 x 10 inches. Therefore, you should consider different ways in which your design can take advantage of smaller parts in greater numbers. In comparison to the larger but fewer parts.

Custom Plastic Mold Manufacturers Focus on Material

It is imperative to focus on the material that you would be using for your products and parts. There are certain designs that allow flexibility, whereas some require specific requirements due to toa particular material.

Rely on your manufacturer’s advice when it comes to choosing the right material. After all, they have the experience as to how a certain material would work with their injection moulding process. They would also be able to offer you an equally good substitute for an expensive material.

After all, they have been in the industry long enough to understand all its ups and downs. They would be the most authentic source of information for you.

Wegbringen

Kaito Mould is among the leading custom plastic mold manufacturers. They have been providing high quality and effective injection moulding services for several years now. Their experience and their knowledge of the industry would help them deliver high-quality parts or components.

They will help you with creating your part design. Furthermore, they would evaluate it for the use in production as well as producing your mold.

You should reach out to them today, discuss your design, and allow them to translate your ideas into reality. After all, we are the leading injection molding company.