Fundición a presión de aluminio frente a otros métodos de conformación de aluminio

Fundición a presión de aluminio frente a otros métodos de conformación de aluminio

¿Cuáles son las diferentes técnicas de fundición de aluminio?

El proceso de fundición a presión de aluminio es un proceso versátil. Permite la creación de formas complejas, pero robustas y eficientes. El aluminio en sí es una gran aleación para la creación de prototipos y productos. La popularidad del material ha llevado a varias técnicas de fundición.

Cada una de estas técnicas ofrece diferentes beneficios. Al mismo tiempo, vienen con su limitación. Sin embargo, es importante que cada tipo de colada produzca excelentes resultados. En este artículo vamos a hablar sobre los diferentes métodos de modelado del aluminio.

Entonces, sin más demora, ¡comencemos!

Diferentes métodos de modelado de aluminio

Los procesos de conformado de aluminio más comunes incluyen los siguientes

- Laminación

- Forjar

- Extrusión

- Fundición

Para cualquier tipo de metal, la fundición es el proceso de conformado más versátil y eficaz. Es posible crear algunas de las mejores, robustas y resistentes piezas utilizando esta técnica. Según las estimaciones del Departamento de Energía de EE. UU., Aproximadamente el 90 por ciento de las cosas fabricadas tienen productos de fundición de metal.

You can apply the same casting technique for aluminum that you would use for other metals. But the most common methods include the Die Casting, Green Sand Casting, and the permanent Mold Casting.

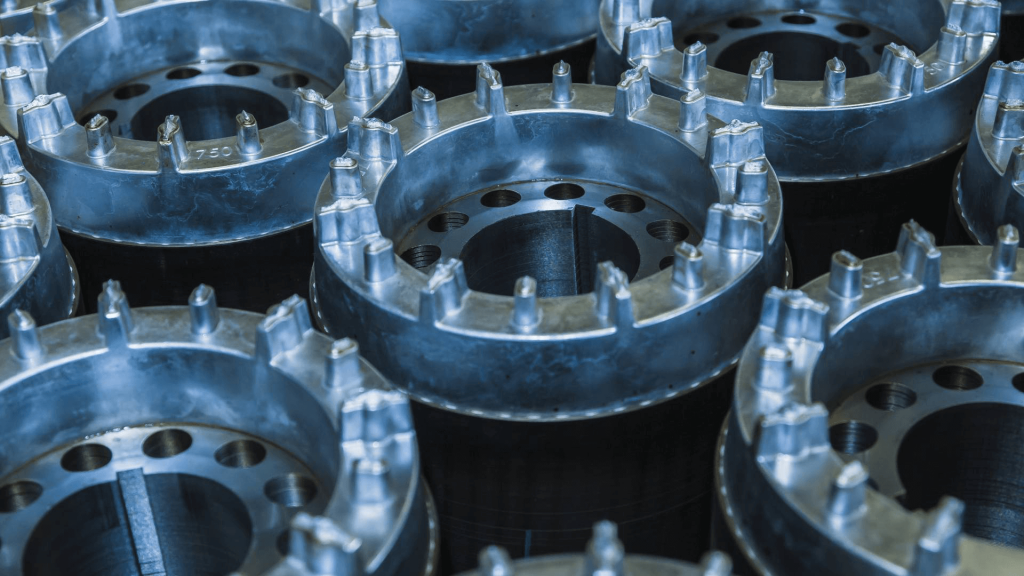

Permanent Mold Casting

Permanent mold casting is among the most common technique for molding metals. It creates a reusable metal mold at an extremely high temperature. When the manufacturer wants to cast-aluminum the mold either should be of steel or gray iron.

The molds two halves are first connected and then they are pre-heated. Once they reach a certain temperature, then its time to pour the molten metal. The metal enters the mold via a ladle. Once the mold is full, give it some time to set and solidify.

After it solidifies, remove it. It is important to take the casting out of the mold as soon as it solidifies as the inflexible mold can result in defects in the casting. After removing the casting, the process is repeated instantly.

Permanent Mold Casting: Advantages

It is possible to recoup the initial tooling cost because of the mold’s reusability. Manufacturers are able to generate high-volume runs using the same mold over and over again.

You do not need of preparation between casting.

The technique offers a high repeatability rate.

With permanent casting, it is possible to achieve high dimensional accuracy. However, for accuracy, you need to have accurately machined mold.

Permanent Mold Casting: Disadvantages

The initial tooling cast is fairly high especially when you compare it to other casting techniques.

The molds are inflexible. Thus, it can lead to defects in casting if they are not removed on time.

In the case of large runs, you may have to replace the permanent mold as they have a short lifespan.

Green Casting Aluminium

Another effective technique for casting aluminum is the Greensand casting. The technique uses clay-bounded, moist sand to create the mold. The first step to packing sand around the desired pattern in order to create the mold cavity.

After that, it is time to remove the pattern. Then, the manufacturer places the mold into a brace. At this stage, the cavity is paired with its other half. This part is similar to that of the permanent mold casting. Once the mold is ready, it is time to pour the molten metal into the cavity.

Now, wait for the casting to solidify. In order to remove the casting, the manufacturer breaks the mold. This step is different from the permanent molding, where, it is possible to reuse the mold. To finish off the casting process, grind the needless features such as the risers and tabs.

Most facilities are able to reuse most of the sand used in this casting process.

Greensand Casting: Advantages

The technique offers diversity in terms of size and weight. It is possible to cast almost any part using Greensand casting.

Both the material and the tooling cost is extremely low.

Greensand Casting: Disadvantages

Every time, you would need a new mold as the process requires to break the previous mold to remove the casting.

The casting surface is not very smooth. You might have to do some additional work on it.

The technique does not offer dimensional accuracy.

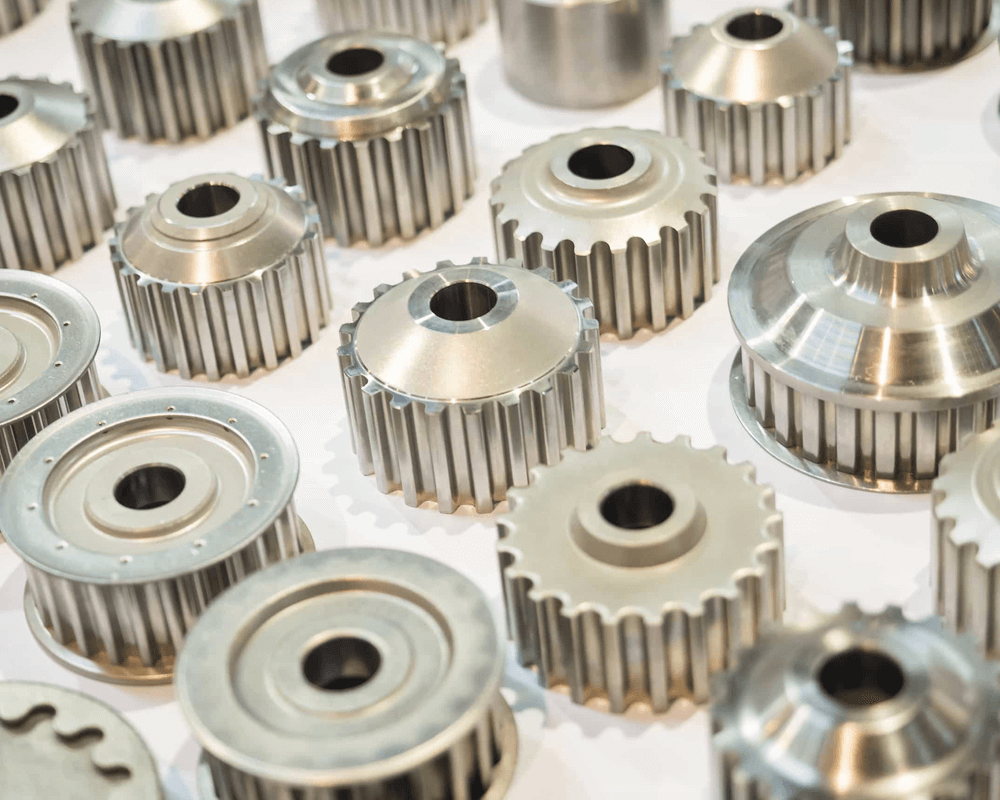

Die Casting Aluminium Process

El die casting Aluminium process is similar to that of the permanent casting. Both these techniques reuse the metal mold instead of disposing of the mold as it is the case in Greensand casting. In die casting, the molten metal injection takes place at high temperatures.

Due to the high pressure, the casting is able to have a better surface finish and it has greater details. However, if not being careful, the injection can lead to a trapped pocket of air. This would have an adverse impact on the durability of the die casting.

Manufacturers would recommend die casting aluminium for mass production of small size parts.

NOTE: The complexity of the process is limited.

Debido a la configuración del aparato de fundición a presión, los fabricantes tienen opciones limitadas en términos de núcleos. Dado que la configuración no permite insertar varios núcleos.

Fundición a presión: ventajas

Con la fundición a presión es posible fundir piezas que tienen un detalle y un acabado superficial superiores.

Los troqueles que se crean con acero para herramientas de alta calidad tienen una vida más larga. Son robustos y resistentes.

Fundición a presión: desventajas

La técnica ofrece una complejidad limitada, especialmente cuando los productos tienen secciones huecas.

El costo inicial de las herramientas es extremadamente alto.

La resistencia del molde puede verse comprometida debido a defectos como la porosidad.

Métodos de fundición de aluminio: comparación

| Coste laboral | Costo inicial | Tolerancias típicas | Volumen típico | Acabado de la superficie | |

| Molde permanente | Bajo | Alto | +/- .01 - .03 pulg. | Altura media | Bueno |

| los | Bajo | Muy alto | +/- .01 - .015 pulg. | Muy alto | Muy bien |

| Arena verde | Bajo | Bajo | + /. 01 - .06 pulg. | Low-High | Average |

Para llevar

There are different methods for casting aluminum, but the most common one is the die casting aluminium technique. This method is highly effective and efficient. It yields projects that do not require additional work after being cast.

Although the initial tooling cost is high, it is possible to reuse the molds. Thus, this is compensation in terms of cost. What more is that the technique has a low labor cost and great tolerance.

We offer the best die casting services. Reach out to us today and learn more about our services.