アルミニウムのラピッドプロトタイピングは、従来の製造よりもどの程度優れていますか?

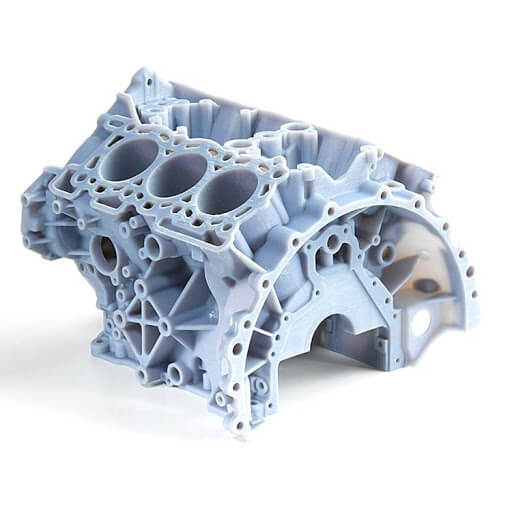

Almost total freedom of shapes and topological optimization

One of the main advantages of アルミニウムのラピッドプロトタイピング is the ability to print intricate and very complex shapes. It’s very simple, just use CAD software free or paid to draw a 3D model of the object you want to print.

Here, the complexity of the object is not a problem. We can therefore give free rein to our creativity. Anything your mind can design; a 3D printer can help you materialize. But, hold on! However, it is better to think of useful things than a Kalashnikov (oops! A bad word). Is not it?

How does aluminum rapid prototyping machine work?

After the design phase, printing is started using the three-dimensional machine. In no time, she creates the object of your choice. Far from the drawing on paper that we get with 2D printers, the device gives you a three-dimensional object.

It deposits thin layers of material on top of each other until the final result is obtained. It is as if you are creating an object from nothing. In fact, you will need the raw materials. We are therefore very far from wanting to play God. It’s reassuring.

Thus, it is now possible to produce アルミニウムのラピッドプロトタイピング products and tools in the industrial world. Several products that cannot be designed by conventional manufacturing processes, because of their complexity. They can easily be created in a professional アルミニウムのラピッドプロトタイピング company.

Major rapid prototyping industries

The fields of application are very varied. With this process, manufacturers according to their sector of activity can:

- Manufacture complex gears and spare parts;

- Replicate human organs

- Build houses in record time;

- Create food

- Design musical instruments like the violin …

Additive manufacturing technologies offer industries an unprecedented number of design options. But, in addition to the freedom of shapes, 3D printing for industry allows topographic optimization.

To put it simply, even with free 3D modeling software, it is possible to find the best possible distribution of material according to the volume of an object.

Thus, it is easy to 3D print objects that have great elastic-mechanical resistance. This method also makes it easy to solve fluid flow problems and improve the thermal conductivity of アルミニウムのラピッドプロトタイピング.

Now 3D printing makes it possible to have very resistant objects. What more? What if we told you that this process also reduces the time it takes to manufacture objects? Find out for yourself.

The aluminum rapid prototyping revolution with 3D printing

For most engineering and design processes, prototyping is a must. Creating a prototype allows you to consider the positive and negative aspects of a project. Having the reduced model of an object on hand allows you to better appreciate its mechanical constraints.

To create a prototype with traditional methods, we generally use the same configuration. The same processes and the same tools as those used for the final product.

This makes the prototypes that one gets quite expensive for the majority of companies. In addition, the time it takes to design just one can sometimes become an eternity if you want to carefully integrate all the details.

How to do effective aluminum rapid prototyping with 3d printing?

With the popularization of new technologies, it is now possible to quickly create effective アルミニウムのラピッドプロトタイピング. Online 3D printing techniques, for example, are very suitable for doing this.

Likewise, as explained above, it is almost impossible to compete with 3D printing when it comes to geometric complexity. The design possibilities it offers are endless! Plus, she gets the job done in less than two.

In addition, the templates can change greatly, especially during the prototyping phase. With a 3D printer, it is possible to modify the size of a prototype in a very flexible way, and this, in record time.

したがって、3Dプリントもコミュニケーションの補助として提示されます。 イノベーションチェーンの各段階で、投資家に提示するためのプロトタイプをすばやく設計できます。 実際、単純な計画や仮想3Dモデルを提示することは、オブジェクトの物理モデルを提示することほど専門的ではありません。

3D印刷では、機能テストが子供の遊びになります

産業およびアルミニウムのラピッドプロトタイピングは、テストはプロジェクトの検証にとって最も重要です。 このステップは、従来の方法で実行すると、一般に長く、非常に費用がかかります。

ただし、プロの3Dプリンターのサービスをリクエストすると、プロジェクトの完全な機械的および機能的なアセンブリを簡単に検証できます。 この検証は、次のような要素に関係します。

- 連動;

- クリップ;

- ネジ…

Whatever the complexity of the tests to be carried out, all you need to do is associate a reliable アルミニウムのラピッドプロトタイピング company.

The drastic reduction of lead times and engineering costs thanks to 3d printers

Did you know? For several years now, 3D printing has been considered as an industrial revolution in its own right. Some even call it disruptive technology.

In addition to the advantages of additive manufacturing in terms of speed, flexibility and freedom of form, this process also enables significant cost savings. All the solutions that save money are good to take, right?

How does 3d printing help in aluminum rapid prototyping?

Concretely, 3D printing allows you to be very fast without losing efficiency. It allows prototypes to be adjusted on demand. Likewise, it encourages the elimination of several stages of the traditional supply chain (supply, storage, distribution, etc.) by resorting to:

- One tool;

- One device;

- A single technician …

Indeed, you should first call on several specialized technicians to carry out the entire design process of a product. Today, one person, expert in アルミニウムのラピッドプロトタイピング technologies, is enough to brilliantly support the entire process.

In the housing industry for example, the revolutionary power of 3D printing has been demonstrated time and time again. It is possible to easily make a 3D printed house in just 24 hours, inexpensively and efficiently.

aluminum rapid prototyping brings wide opportunities

Think about the possibilities that this offers. All you have to do is select the site where you want to build housing. As soon as the raw materials are in place, the use of a 3D printer allows the building to be built in just one day. It will be as if the house came out of the earth by magic!

The huge cost and logistical hurdle of transporting parts and building materials from factories to the construction site is almost completely eliminated.

結論

Compare that to the cost of a traditional construction project and the six- or seven-month construction time that the industry uses to. You will then understand the extent of the potential disruption (luckily positive) that アルミニウムのラピッドプロトタイピング brings to the industry.