Patru pași simpli pentru realizarea de prototipuri de piese din plastic

Pași eficienți pentru a asigura calitatea pieselor din plastic prototip

Există mai multe premise necesare pentru ca o piesă sau un produs din plastic să fie lansat pe piață. De exemplu, funcționalitatea produsului, estetica și multe altele. Realizați toate acestea cu un efort minim, producătorii de se bazează pe prototip de piese din plastic. Ei sunt capabili să rezolve aproape toate erorile înainte de a introduce produsul pe piață.

Prototiparea este cel mai bun mod de a aborda toate problemele legate de controlul calității. S-ar asigura că piesele și componentele sunt de calitate superioară. Cu ajutorul prototipurilor, este posibil să reduceți timpul de introducere pe piață.

În acest scop, vom vorbi despre pașii simpli ai tehnicii de turnare prin injecție și impactul acesteia asupra industriei prototipurilor din plastic.

Realizarea de prototipuri de piese din plastic

Turnare prin injecție

Printre diferitele procese de prototipare, turnarea prin injecție este cea mai proeminentă tehnică de prototipare pentru plastic. Este eficient pentru crearea tuturor tipurilor de prototipuri din plastic. Acest prototip din plastic acționează apoi ca ghid de bază pe care trebuie să îl urmeze producătorul în faza de producție în serie.

Cu prototipurile, producătorii sunt capabili să se asigure că ideea lor nu numai că are valabilitate, dar este, de asemenea, la înălțime. Produsul pe care îl lansează are o oarecare utilitate pe piață. În plus, pot primi feedback în timp real și pot face modificările dorite în produs la un cost minim.

Acestea sunt capabile să identifice aproape toate erorile potențiale, reducând astfel riscul apariției unor probleme după ce mergeți la producția la scară largă. La urma urmei, o eroare identificată după producția în serie nu numai că ar fi necesară mult timp pentru a fi corectată, ci ar fi, de asemenea, extrem de costisitoare. Acesta este un lucru pe care producătorul tinde să îl evite cu orice preț.

Utilizarea software-ului pentru imagini 3D

In most cases the producătorii de use 3D animation or imagery software to create the design. After they finalize the design on the computer, the next step is to replicate the same design using ABS plastic. For this purpose, they either use a 3D prototyping mold or a 3D printer.

NOTE: Manufacturers might not use the actual material required for the final product for prototyping. The main objective here is to give clients the feel and look of the product for better understanding.

Once, the manufacturer and client see the product prototype in person, they would be better able to make changes to it. They would know actually what things require to enhance and what needs to be eliminated. It is possible to expose the design flaws via prototyping.

Injection molding prototyping is the biggest step in the product control process. It ensures that the product is according to the requirements and it also oversees its creation process.

Make a Plastic Product Design

Creating a design or concept is the first step in manufacturing. Regardless of what they are manufacturing, may it be a packing product, an electronic device, or a garment, you need to have the basic design. This step is no different in terms of plastic parts.

When you are creating the design for plastic parts, you need to pay heed to its functionality and the feasibility factor. It is equally important for the idea to be doable. If the idea does not have any use in the real world, it is simply a waste of money and effort.

To ensure the success of your product, you can either reach out to professional experts for help, or you can rely on 3D prototyping techniques. Collaborating with the experts would be fruitful. Just make sure that you do not have any communication gap.

You should provide them with as much information as possible regarding your idea. There are different formats that you can use to create the digital file of your concept. For example, you can go with the stl file or the stp file. To create these files, you would be using different CAD software.

If you are looking for something easier to present your idea in an effective manner, try using animated videos or slide shows.

Prototype Plastic Parts Product Engineering

At this point, everyone has approved the product design. It has even cleared the functionality standards and everyone believes that idea is doable. It is time for the product engineers to step in. To create your plastic product, the engineers would search for the requirements of prototype plastic parts.

Serviciul de prototype plastic parts manufacturers use steel tools for the prototyping purpose. Therefore, it is important to taper the material in order to ensure a seamless and smooth injection. For instance, you need to have the right thickness for the part’s wall. There should no be undercuts.

All this is important as it would prevent the steel halves to stick to one side of the tool, or cracking. Experienced manufacturers find the gates to which the plastic needs to injected. In addition, they would assess the plastic material within the gates.

They would even be able to adjust the wall thickness in order to ensure that correct and smooth flow of material into the entire gate. There will be no wastage in terms of overflowing. Manufacturers are well aware of the factors that can make the entire process go awry such as the trapped air. So, they would try their best to make the process go as smoothly as possible.

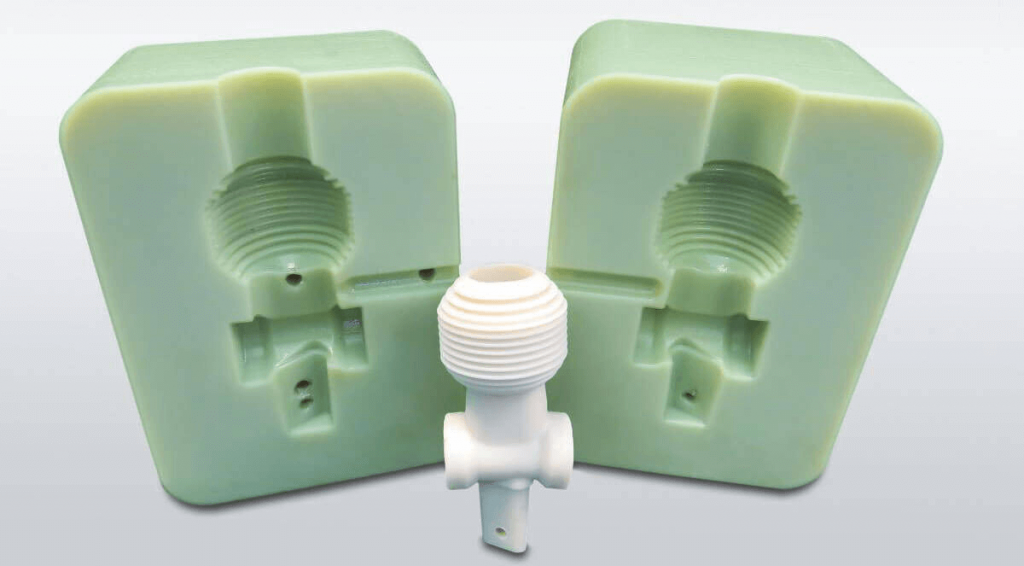

Creation of the Mold for Plastic Parts

In the prototype plastic part manufacturing, the creation of the actual mold is the most vital process. Since the ideas and the concepts are fully engineered, it is time to step towards the creation of the actual mold. The injection mold technique uses plates to push a part of the mold, while there are water lines that responsible for the cooling process.

In the case of complex and complicated design, the engineers would require steel tools along with other pieces. Moreover, with technological advancement, there are other effective ways to create molds.

Using Injection Molding Machines for Plastic Parts Prototyping

Once you create the mold, the next step is to place the mold into an injection molding machine. This machine would then use the mold to create the prototype. The process involves the injection of melted plastic while the 2 halves of the molds are held together via clamp through extreme pressure.

This pressure is in the form of hydraulics. As the material forces its way into the mold, the water lines would cool it down. Thus, resulting in quick solidification.