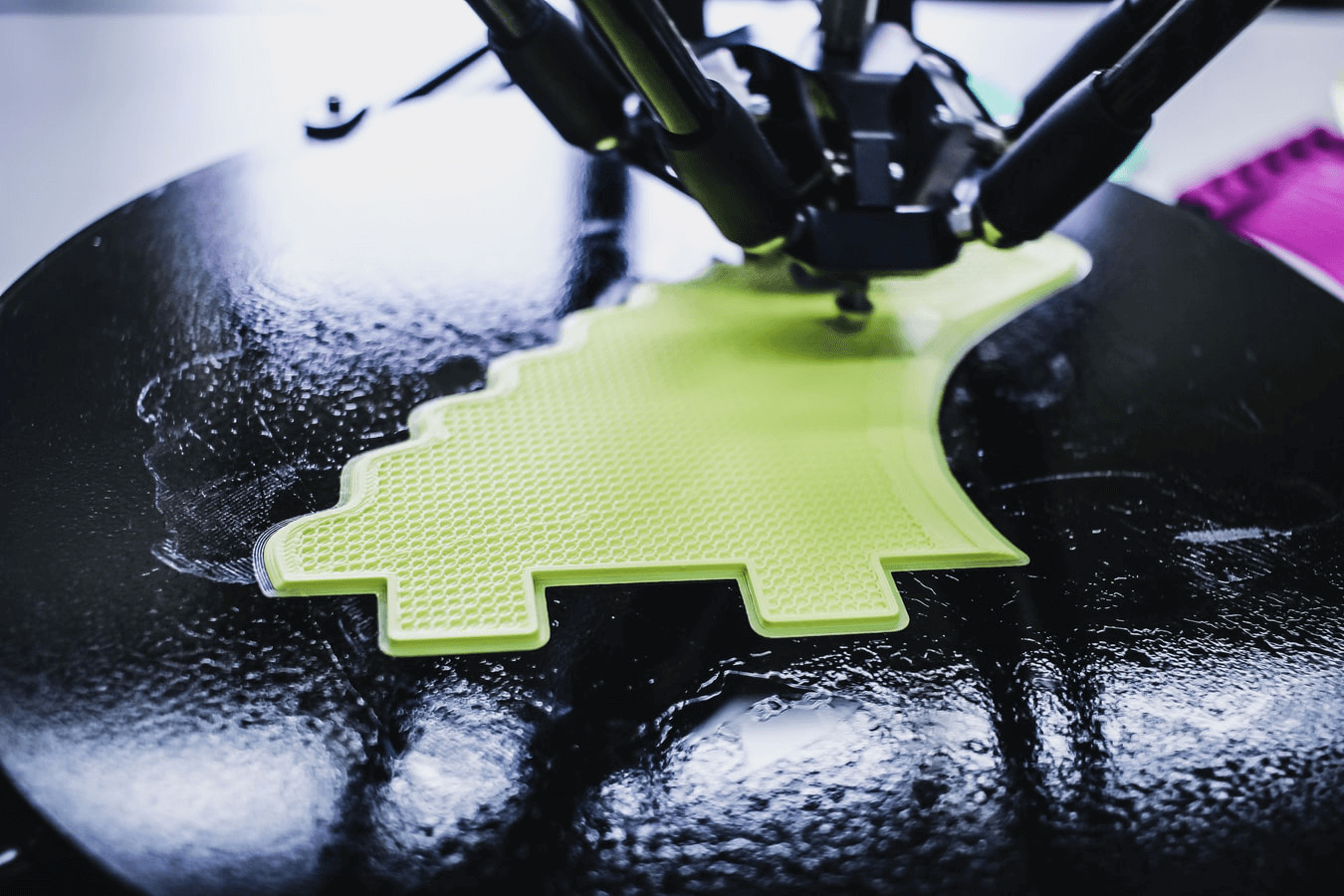

Simple rapid prototyping techniques and process guide One of the main elements that characterized our blog was the innovation brought by Rapid prototyping 3d printing. It got famous in the various areas. For instance: Medicine Technology Society and art It was the recurring element in each of our articles. But with this in-depth analysis, I wanted to focus […]

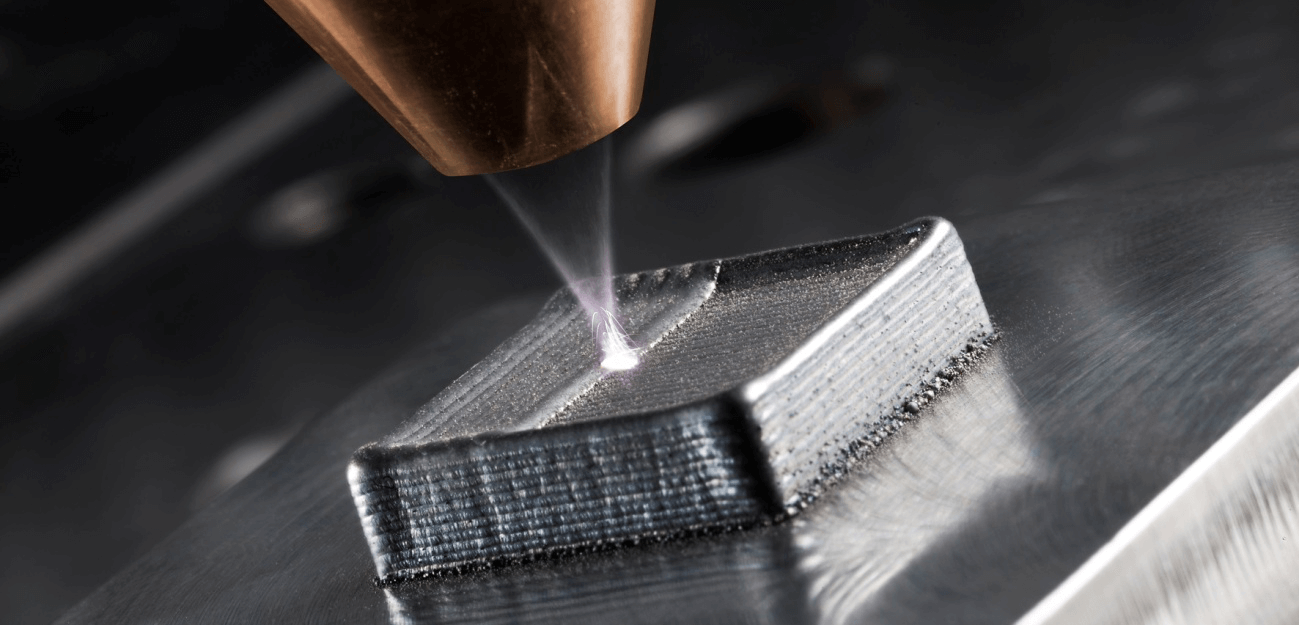

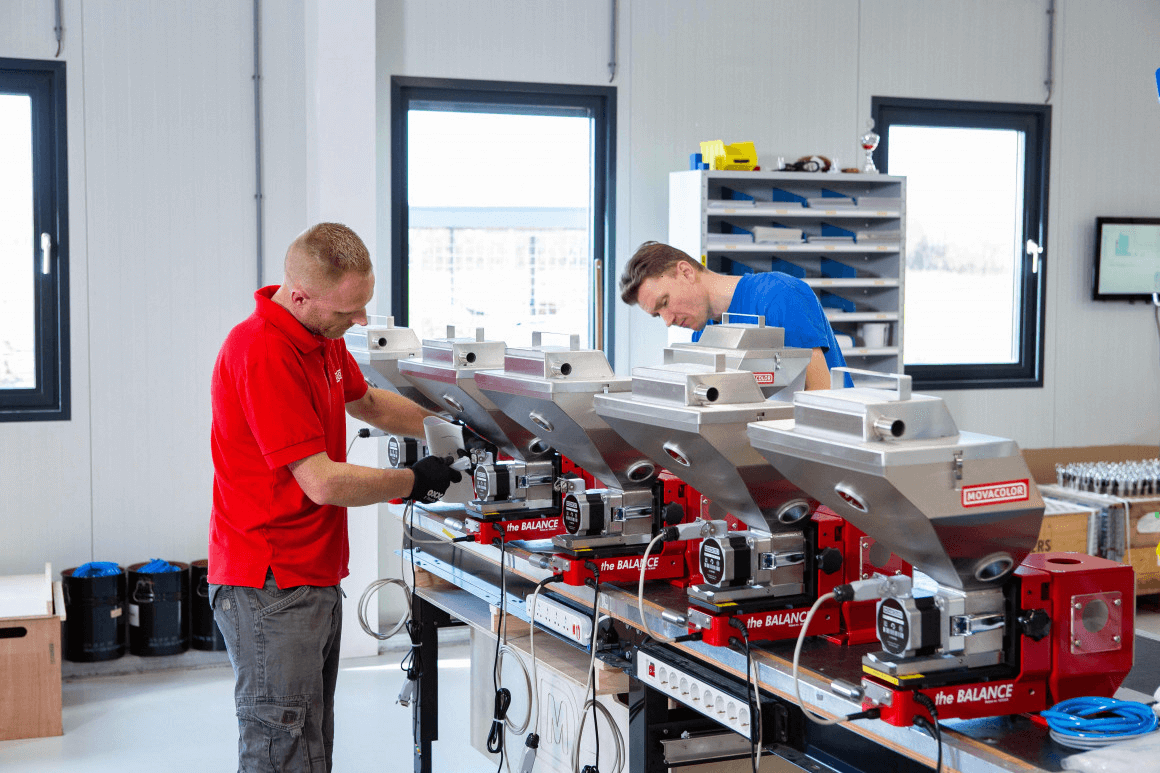

A comprehensive guide to understanding rapid tooling for moulding techniques Rapid tooling molding introduction Rapid tooling molding is the most popular topic in the industry in recent years. 3D printing technology is one of the rapid prototyping technologies. Similarly, RP technology, as the name implies, is a technology that can produce the required prototype in a short time. Rapid […]

An introduction to die casting process steps What is Die casting aluminum? Die casting aluminum is one of best economical procedure. And it is also one of rapid process of forming. One major advantage of this procedure of production is it has the ability to produce thousands of castings. Furthermore, this procedure can produce castings more […]

An Introduction to rapid prototyping and manufacturing companies Why Rapid prototyping services and manufacturers Rapid prototyping services and manufacturers world is changing faster and faster. What used to take years to evolve today takes months or even weeks. And to keep up with the times it is essential to adapt to these rhythms. For this reason, […]

Aluminium Die Casting Manufacturer and Rapid Prototyping The low melting point of aluminum die casting manufacturer & rapid prototyping allows the use of a permanent mold. Similarly, we use this steel to make foundry parts. In die casting, an injection piston pushes the liquid aluminum into the mold cavity. Later, it compresses the part during solidification. Typically, […]

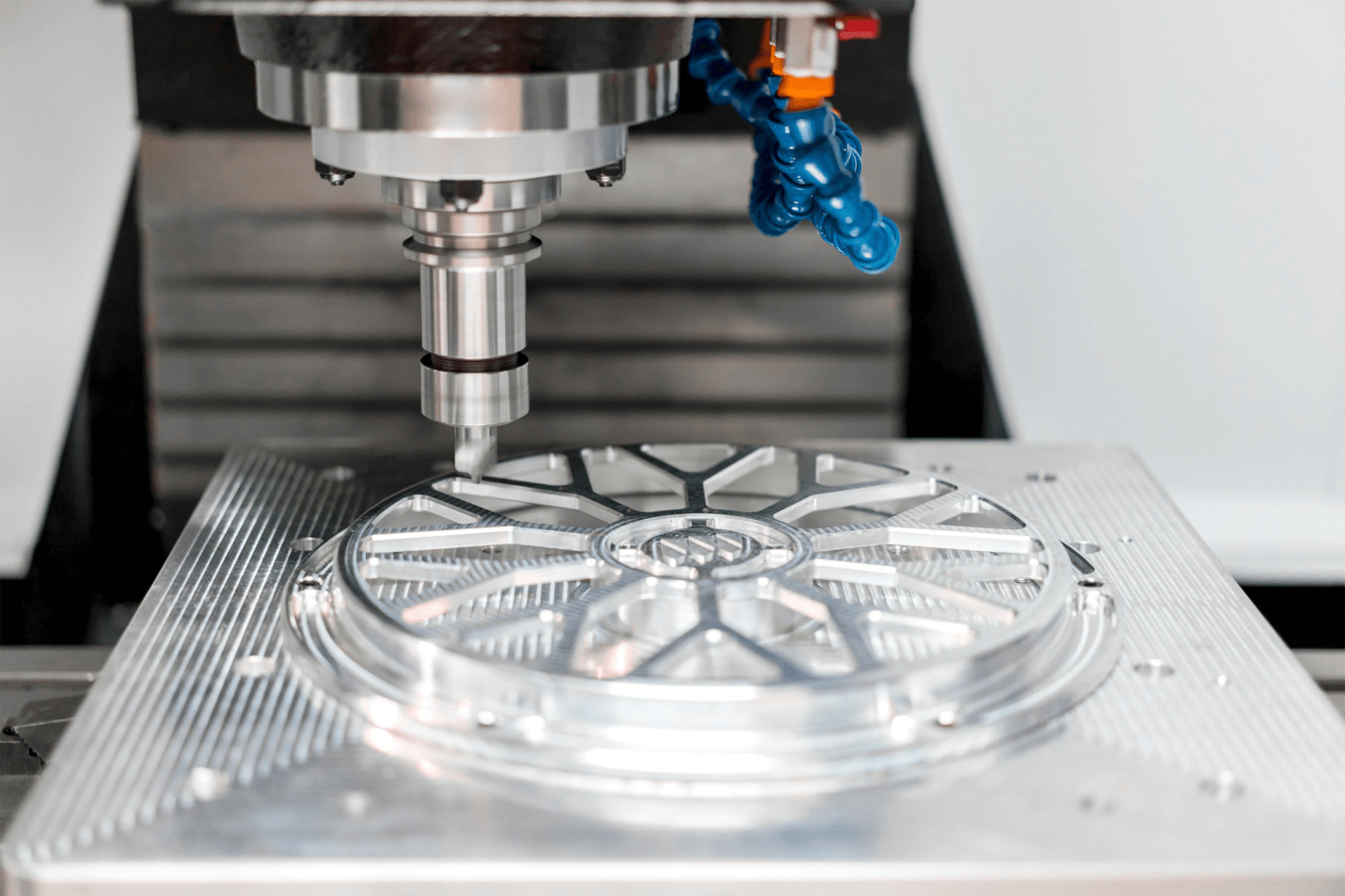

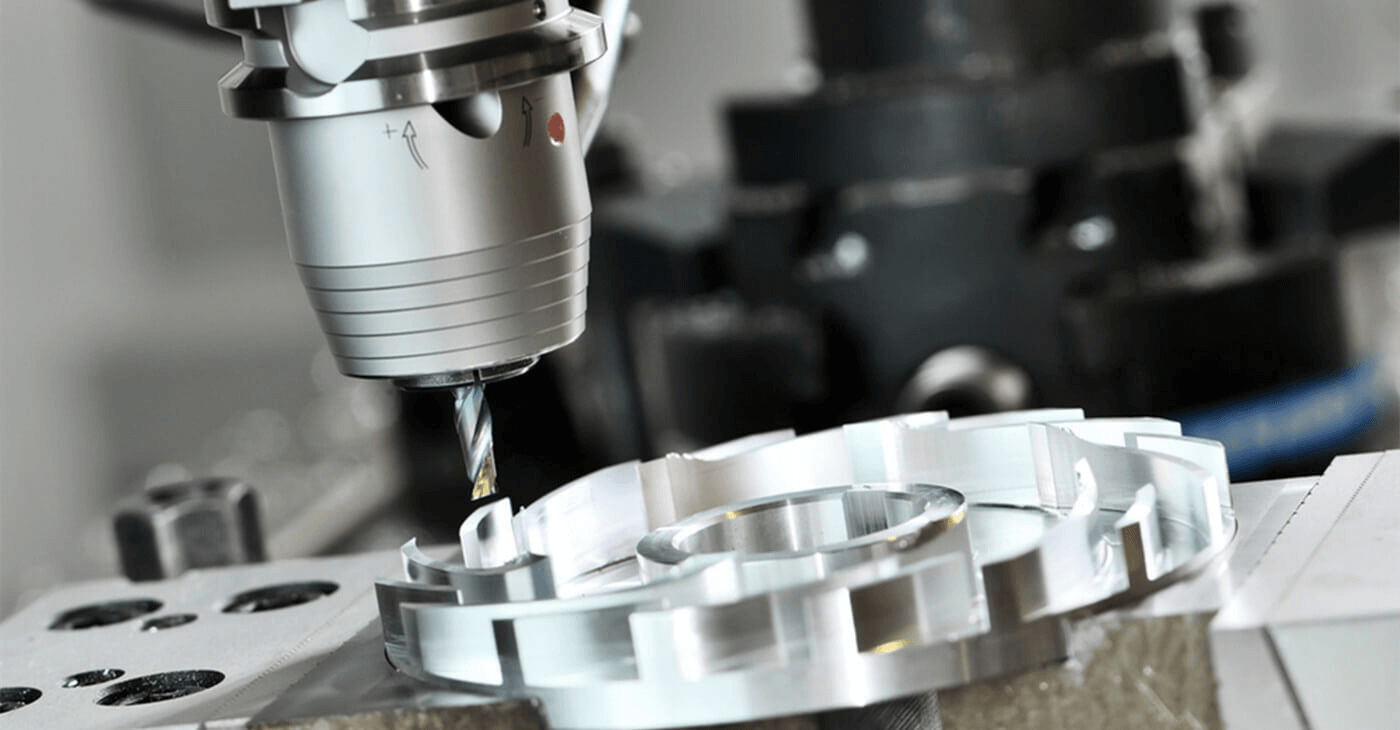

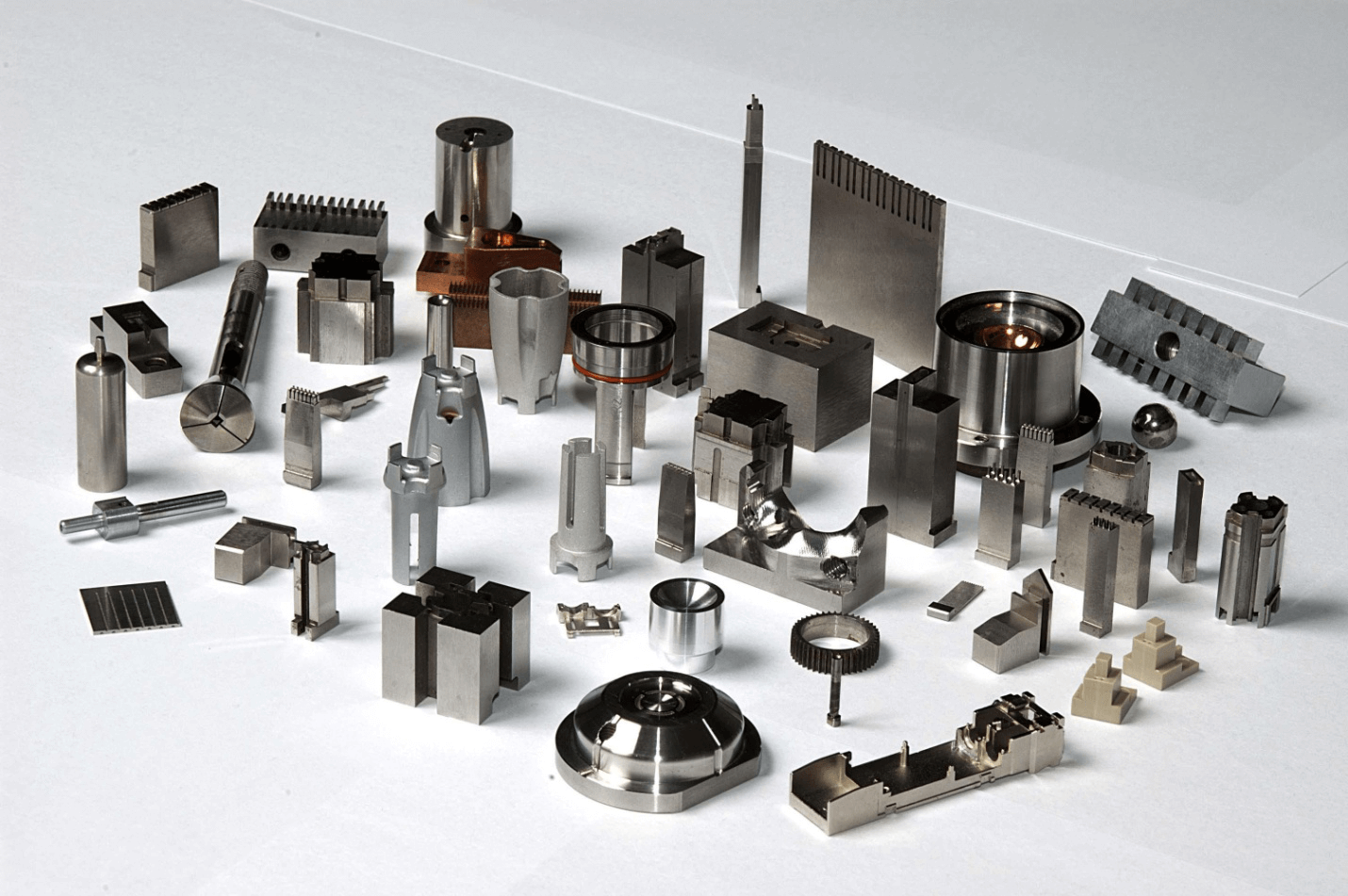

CNC machined parts are so simple to understand An introduction to CNC parts rapid prototype Today the use of CNC parts rapid prototype has become incredibly important for modern technologies. And CNC parts and rapid prototyping is in fact the innovative form of prototyping.Today successful businesses are making use of new and advanced methodologies in the progress […]

Rapid 3D prototyping: what it is, how it works and what it is used for? What is 3d prototype manufacturer & 3d rapid prototype? By now we often hear about 3d prototype manufacturer & 3d rapid prototype. Many are those who do it by trade. Similarly, many others would like to approach this technique to improve […]

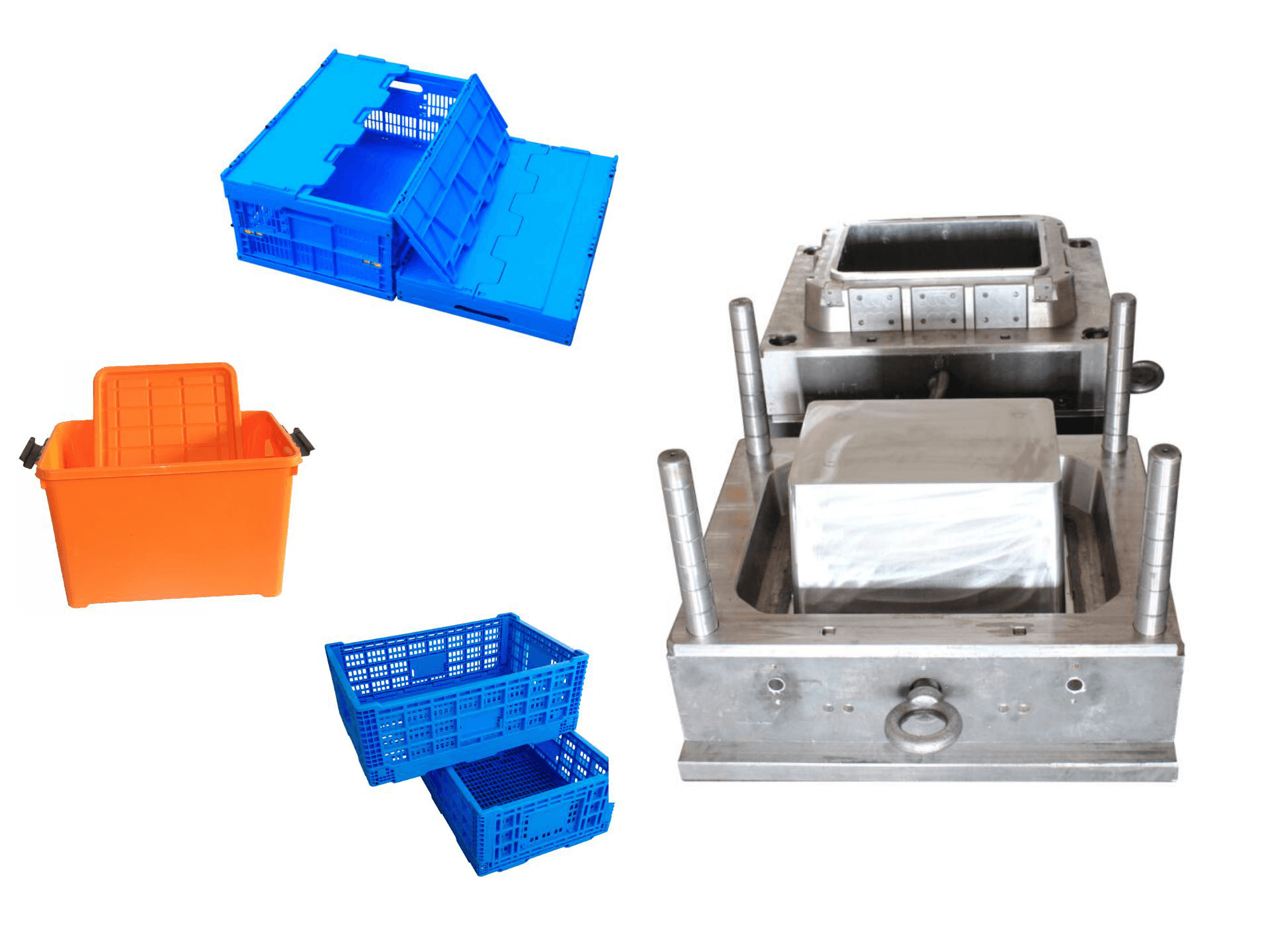

Custom Plastic Parts Manufacturers: How It’s Done? Regardless of your reason for reaching out to custom plastic parts manufacturers, it is also important to have a basic understanding of how the manufacturing process is conducted. In addition, you need to know about the modern and sophisticated model building techniques. In this blog post, we will […]

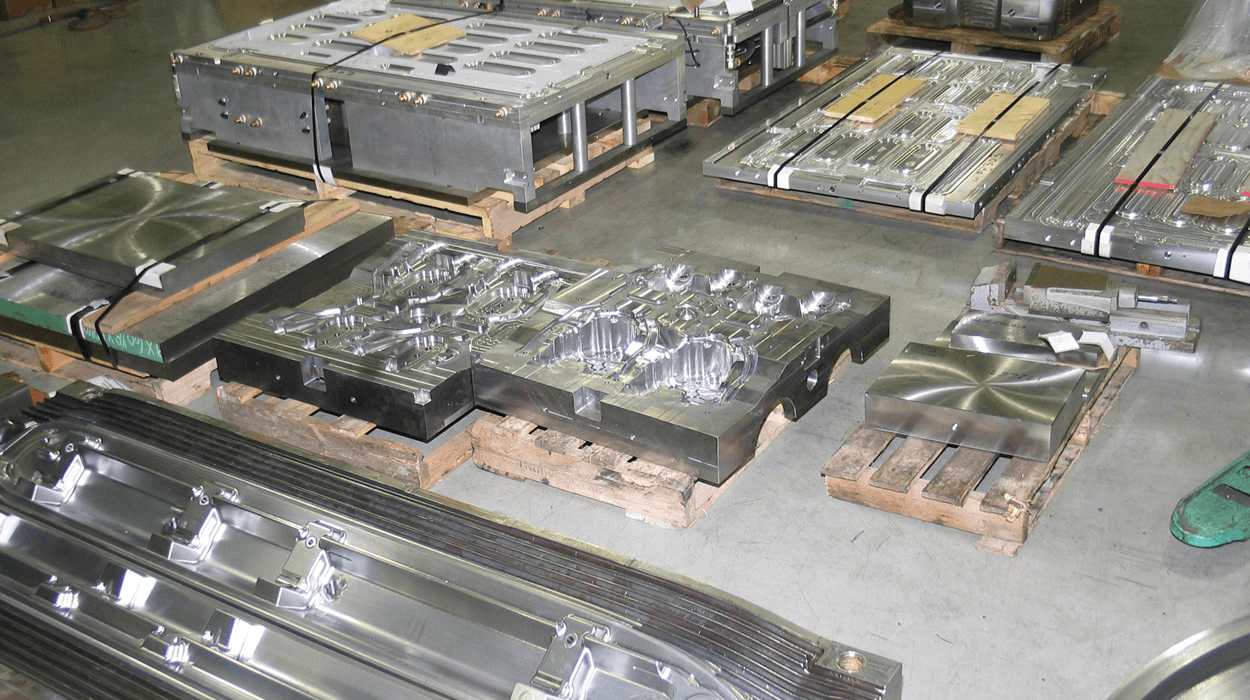

How do Custom Plastic Mold Manufacturers Make Molds? When it comes to manufacturing your custom parts, the most important thing is the mold. If you have an error-free mold, you can have error-free parts and components. Therefore, you need to understand the basics of how custom plastic mold manufacturers make molds. If you are aiming […]

Plastic Die Mould Manufacturer: The Types of Plastic Moulding The most obvious reason for reaching out to a plastic die mould manufacturer is; you are in need of either a custom plastic product or part. There are different ways of moulding a plastic, each having its benefits and demerits. If you have a basic understanding […]

Plastic Molded Parts Manufacturer: Extrusion Molding Vs Thermoforming A plastic molded parts manufacturer offers diversity when it comes to moulding techniques. In addition to the popular molding methods such as injection and rotational. There are two more effective moulding techniques namely Thermoforming and Extrusion Moulding. Both of these techniques offer a number of benefits. They come […]

What can ABS Plastic Molding Manufacturers Mold from ABS Plastic? Acrylonitrile butadiene styrene (ABS) is among the most common type of thermoplastic polymers that ABS plastic molding manufacturers use around the globe for numerous commercial, domestic, and industrial applications. ABS plastic offers a number of benefits, thus making it the first choice for moulding purpose. What […]