Expert Rapid prototyping services and manufacturers review in 5 Minutes

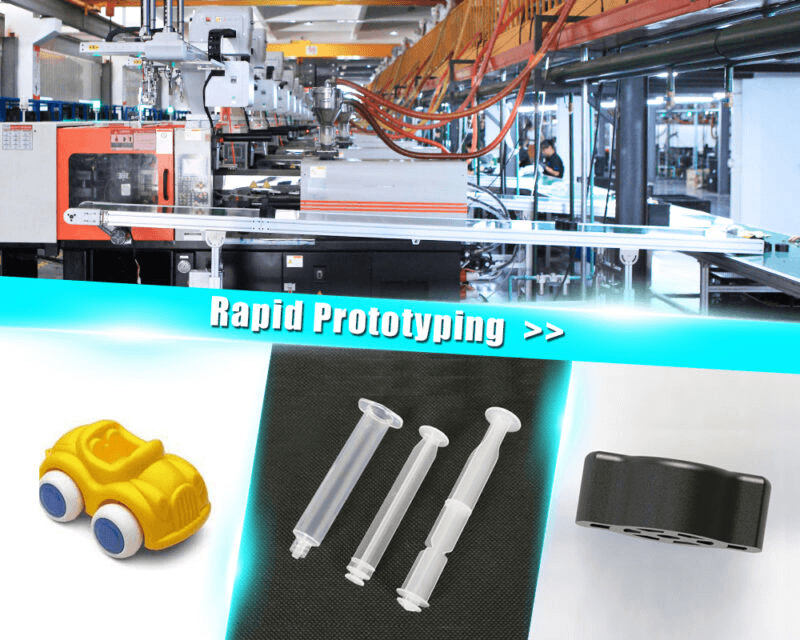

An Introduction to rapid prototyping and manufacturing companies

Why Rapid prototyping services and manufacturers

Rapid prototyping services and manufacturers world is changing faster and faster. What used to take years to evolve today takes months or even weeks. And to keep up with the times it is essential to adapt to these rhythms.

For this reason, it is important to exploit the most modern technologies and skills of professionals. Therefore, it is very important to significantly reduce the planning and time of the finished object.

The Rapid Prototyping is not just the result of reverse engineering. But it is a substantial part of subsequent development.

Rapid prototyping with 3D printing

The rapid prototyping with 3D printing is revolutionizing the mode of production. The flexibility it provides brings great opportunities. Its process is simple and easy. Moreover, it reduces cost. Therefore, rapid prototyping services and manufacturers find it easy to maintain product flow.

Rapid prototyping services and manufacturers with decades of experience are serving this industry. These are precious ally for all those companies and designers who want to make a prototype and test its efficiency.

Today the main challenge for companies is to speed up the production process. Having a realistic prototype in a short time becomes strategically relevant. Because it allows you to glimpse and eliminate design errors.

It would otherwise emerge only after the start of production. The 3D printed prototype can be tested and modified without serious waste of time and money.

But in reality, what is 3D rapid prototyping manufacturing?

We can define rapid 3D prototyping as the set of technologies. That makes it possible to build a prototype in a few hours. It comes with extreme ease, also reducing construction costs.

The rapid prototyping techniques vary with the rapid prototyping services and manufacturers.

Thanks to the support of 3D printers and industrial engineers can perform multiple revisions of the prototype in less time. They can perform more in-depth tests and reduce time to market.

Furthermore, the physical models are able to facilitate the communication of the concept. Similarly, they allow to obtain detailed feedback from customers and distributors.

A realistic prototype therefore becomes an extremely effective marketing tool. The possibility of obtaining a real object through rapid 3D prototyping offers the company numerous tools.

These tools improve product development, with low costs. Each department, of rapid prototyping services and manufacturers can have the real object in their hands. This all can be possible at the moment when the product is ready.

What can rapid prototyping services and manufacturers do for you?

3D printing is a rapidly evolving technology. To use it you need a lot of experience, as well as patience. In fact, with the current solutions available we are still far from obtaining results quickly.

Furthermore, printing errors are very difficult to avoid. Especially, if you do not have experience in choosing the design and process parameters. The printers are slow. They can take tens of hours to complete the production of a single piece of a few centimeters in size.

Rapid prototyping services and manufacturers techniques

The 3D printing has greatly increased the ability to realize. Even the most complex prototypes,

substantially giving maximum freedom to the achievable forms. On one hand the 3D printing allows to obtain a high reliability of the piece compared to the design. It provides a perfect production.

On the other hand the high speed and cost-effectiveness of the parts guarantee the

maximum customization. It gives an absolute uniqueness to each prototype made.

In both cases the huge advantage of 3D printing lies in the fidelity of the piece.

With rapid prototyping services and manufacturers, you can get functional prototypes quickly. Moreover, it provides low costs starting from a simple CAD model.

Rapid prototyping services and manufacturers for your business

Using rapid prototyping to test final parts allows you to launch your product on the market before the competition. Such as, with 3D printing it is easier and faster to make changes to the:

- Design

- change materials

- Shapes

- colors and

- experiment with factors

Such as the strength and feasibility of a product while reducing costs.

Thanks to the use rapid prototyping services and manufacturers, it is possible to create any type of three-dimensional model. Similarly, special software plays an important role in the whole process.

With these special printers, it is possible to save well over 35% on labor and material costs. It also saves energy between 41% and 64%.

3D rapid prototyping services in major industries

Now we hear more and more often about rapid 3D prototyping. And there are more and more companies that would like to approach this technique. They do this to improve and speed up their production processes.

To be clearer, rapid prototyping means using three-dimensional CAD modelers. We use it from desktop to convert 3D files into STL format and create prototypes in a short time.

All this therefore consists in the application of a series of industrial techniques. It allows prototypes to be created. That is nothing more than the initial elements of a production series.

Why do rapid prototyping services and manufacturers prefer 3D printing?

With 3D printing it is possible to create prototypes. Rapid prototyping services and manufacturers experiment in a simpler and decidedly cheaper way.

3D printing is today the best prototyping and design technique. This is because; it allows the independent creation of the various pieces. That makes up an object. And they get assembling later. It happens without having to create the single piece.

But what are the best 3D printers around?

Rapid prototyping services and manufacturers can offer you some of the best models of 3D printers. You can choose a number of designs as well. But it depends whether you choose an expert or not.

The best method is to check qualification of such company. You may ask previous projects too.

The prototype is the first element of a future series. Its purpose is to provide data for the evaluation of costs. It maintains functionality and market responses.

Rapid prototyping is a set of processes that allow the creation of a prototype.

The possible fields of application are infinite. It ranges from architecture to engineering. Moreover, it goes from industrial design to the creation of gadgets, from jewelry to medical.

The materials that can be used are many and with different physical characteristics.

The advantages of Rapid prototyping services and manufacturers

- Reduction of prototyping costs:

- Print prototypes in a few hours

- get feedback

- finish projects and

- repeat the cycle until the models are perfect

- The costs for creating clichés for injection printing are cut

Shorter design times: compress the design cycles by printing directly in 3D in the workplace.

Rapid prototyping services and manufacturers improve communication and increase interactivity. They create a realistic 3D model. It can be touched transfers much more information than a project displayed on paper.

The critical points are immediately perceived.

Reduce development costs: It reduces prototyping and tooling costs. Similarly, it promptly identifies any errors. Systems are capable of generating prototypes in a matter of hours.

Prototyping times vary according to the:

- printing technologies used

- the size and the number of prototypes

Rapid prototyping services and manufacturers Technology

Prototypes are essential in every phase of development of a new product. For this reason 3D prototype is the solution.

Through the laser sintering process, it is possible to create prototypes and experiment easily. It is economical, creating components and materials suitable for visual and functional tests. Furthermore, it is one of the most precise, versatile and most used 3D printing technology.

3D printing is a rapid prototyping technique. It allows you to create prototypes and components. It provides:

- high strength

- stability and

- precision in a short time and at low costs

This technique makes use of thermoplastic materials. They are capable of giving particular and specific mechanical properties to the molded object. It is ideal for following the phases of a project during its development. It gives a proper time before final production.

Rapid prototyping services and manufacturers allow you to fully reproduce an object. It gives you following areas to study:

- produce study models

- perform dimensional tests

- redesign mechanical parts

- printing solid reproductions in various sizes

- reductions,

- enlargements

How does rapid prototype 3D printing work?

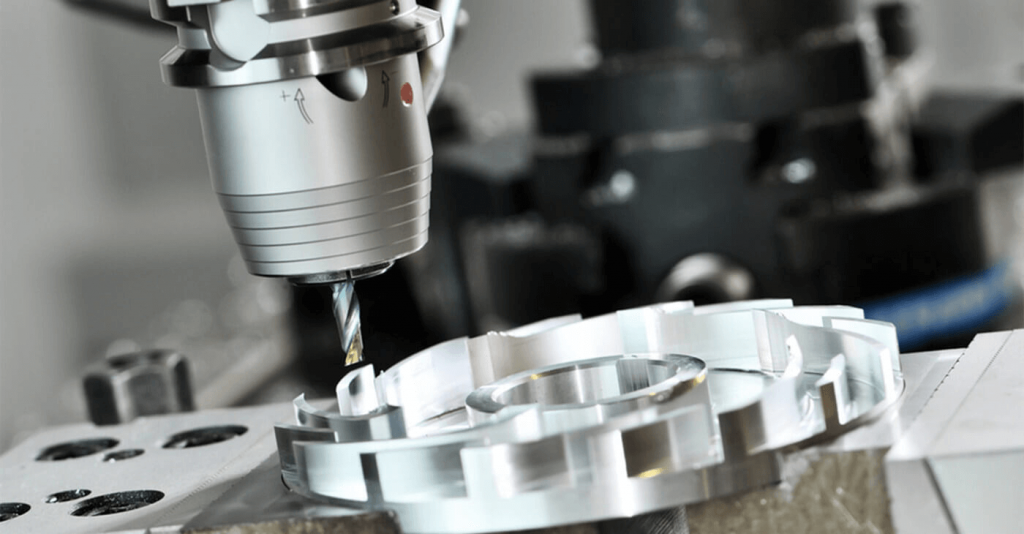

Mostly, rapid prototyping services and manufacturers use a deposition printer. It allows you to print objects up to 70 cm in height. Thus it produces large high-definition prints. A UV laser printer that works with resins photo reactive.

It is able to reach a very high resolution. It gives completely smooth surfaces and models. They are resistant to friction, bending and ironing. Similarly, they remain stick to the original dimensions of the CAD projects.

We can evaluate together the best use of this technology. Rapid prototyping services and manufacturers‘ professionalism can make the best of it. You can adhere with making the most of the potential of 3D printing.

It starts from the optimization of the design up to the post-production. And, it ends with processing of the printed object.

3D printing is used as a prototyping method. It addresses 360 ° to all sectors. That needs a demonstration model for following sectors:

- from mechanicsto marketing

- design

- from industry to medical

- from jewelryto dental to teaching

Rapid prototyping services and manufacturers for everyone

3D printing is one of the most debated topics in recent years. But often on the media it seems like a science-fiction technology. Similarly, it seems out of reach. But instead it is here; ready to be used in the most diverse sectors.

Let’s try to briefly explain what Rapid prototyping services and manufacturers can do to you? And what it can serve you?

Generally, 3D printing is part of a family of technologies. It goes under the classification of ‘ rapid prototyping techniques ‘. The rapid is not so much to indicate the time of realization of an object.

Since obtaining a solid by depositing very thin layers cannot necessarily be very rapid. But it indicates the advantage of not needing expensive pre-production phases. The clear example is mold making.

It also has the advantage of allowing rapid prototyping services and manufacturers to deposit the material. It has vast options to remove the part that is not needed. Furthermore, we can see this in milling.

Generally, it is sufficient to create a model with a 3D CAD. After a few post-production phases it is possible to ‘print’ the real and functional object.

In addition to this, the type of object creation process makes it possible to create shapes and geometries. Those are impossible with traditional methods of molding.

The impact of rapid prototyping services and manufacturers on global industries

Today rapid prototyping services and manufacturers are about to change production practices. It is especially for small and medium-sized companies.

There have been three pivotal events. They can testify to this passage. In 2000, a Belgian company specializing in software related to 3D printing and rapid prototyping services, collaborated with the Swiss hearing aid manufacturer.

It was Phonak to develop the first process of hearing aid-produced 3D molding devices. It demonstrated that high volume production is also sustainable via 3D printers.

In detail, 75% of the car was made by additive manufacturing. Furthermore, it used a material made of 80% ABS and 20% nylon. In short, it proved that even complex objects of large dimensions can be produced by printing them.

The third event dates back to January 2016 when a team from the University of Northwestern, Illinois developed low-cost technology. It was for printing with metallic materials.

This new process involves the use of:

- an ink composed of metallic powder

- a solvent and

- a binder

It is sprayed through a nozzle. It is common with the classic inkjet printers. Instead of resorting to the use of laser, it is sufficient to pass the model in a furnace.

Rapid prototyping services and manufacturers conclusion

In conclusion we can note that today a small company can have several tools and technologies available. They require lower investments than the start-up of a classic industrial production. And above all, they provide greater flexibility. In whole process, rapid prototyping services and manufacturers help you a lot.

It is evident that the large industrial groups have resources and market segments. They guarantee them to maintain their leadership. But niches and sectors in which it is possible to insert themselves as production model.