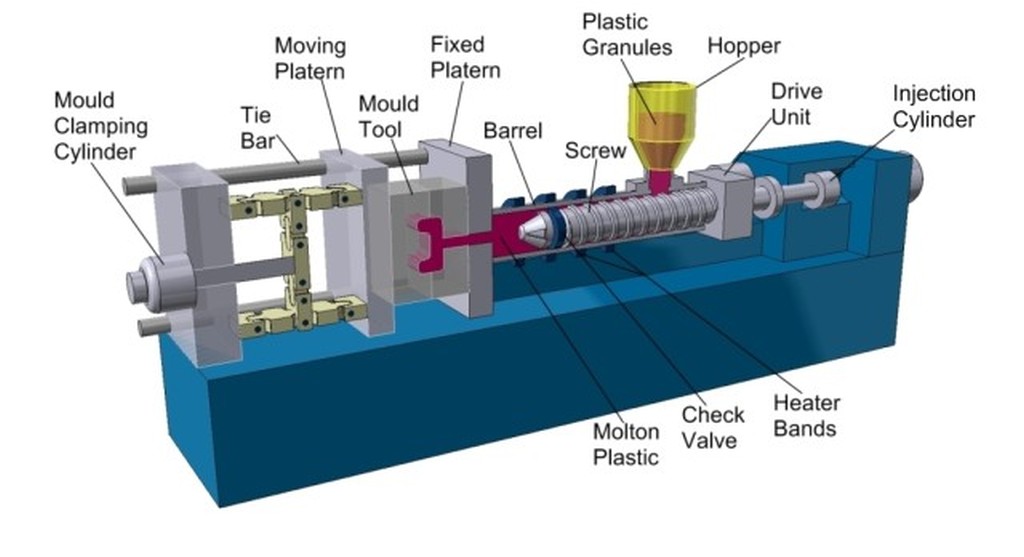

The mechanics of Injection Moulding Die Manufacturer Industries around the globe engaging injection moulding die manufacturer for mass production processes. After all, injection moulding is a reliable and efficient manufacturing process. It is excellent for the production of parts from the thermosetting plastic and thermoplastic materials. There has been an increase of 0.9% in the […]

Tips on Choosing the Right Injection moulding products manufacturers The injection moulding process is among the first choice for producing plastic parts. Due to advance features, durability and enhanced efficiency it is easy to make a decision. There are several manufacturing techniques. Thus, offering your versatility. Once you finalize your injection moulding technique, next comes […]

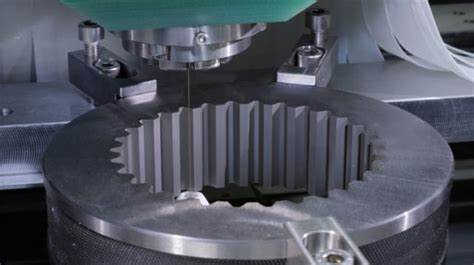

Precision hardware can be opened according to production needs. After that, some small parts can be cut by gongs or CNC processing. However, precision hardware must be opened for punching, and then welded, then sanded and sprayed. It’s done. It should be noted that the small parts also need to be plated or oil sprayed […]

1. Mold Steel Steel is the decisive factor in the quality of injection molds, and choose the right steel is the top priority. The standard for choosing steel is ①Injection molding material requirements Different plastics should use different steels, such as high polishing requirements, corrosion resistance requirements, etc. ②Price Steel can be used as well, not the […]

The definition of precision injection molds is determined according to two indicators, one is the precision of the processing equipment, and the other is the error caused by the mold processing. The comprehensive level of an injection molding machine is determined by the weight error of the injection molding machine. The error is less than 0.5% for […]

Polyetherimide (PEI) is valuable in the medical, electronics and other fields that demand exceptional strength and rigidity in high-heat applications. The amber, high performance polymer offers excellent dimensional stability, combined with broad chemical resistance. PEI is ideal for hot air and water environments and is very hydrolitaclly stable with excellent property retention. With high-performance electrical […]

A polyester resin, thermoplastic polybutylene terephthalate (PBT) offers good electrical, mechanical and thermal properties with excellent chemical resistance to a variety of chemicals including aliphatic hydrocarbons, oil, grease, dilute acids and bases, and detergents : Excellent dielectric strength Superior electrical properties Chemical resistance Rigidity Toughness Resistance to solvents, grease, oil, chemicals and solvents Flame retardance […]

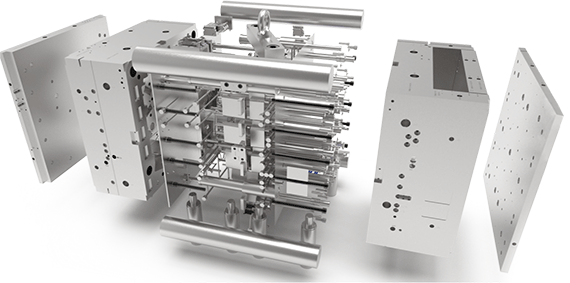

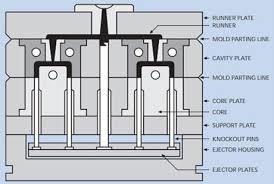

Low / High Cavitation Single cavity molds are designed to produce one part per cycle. They are a cost-effective approach when part volumes are low as they are less expensive to build. They also have a shorter lead time. The disadvantage is a higher piece part cost in molding production. Multi-cavity molds produce more parts […]

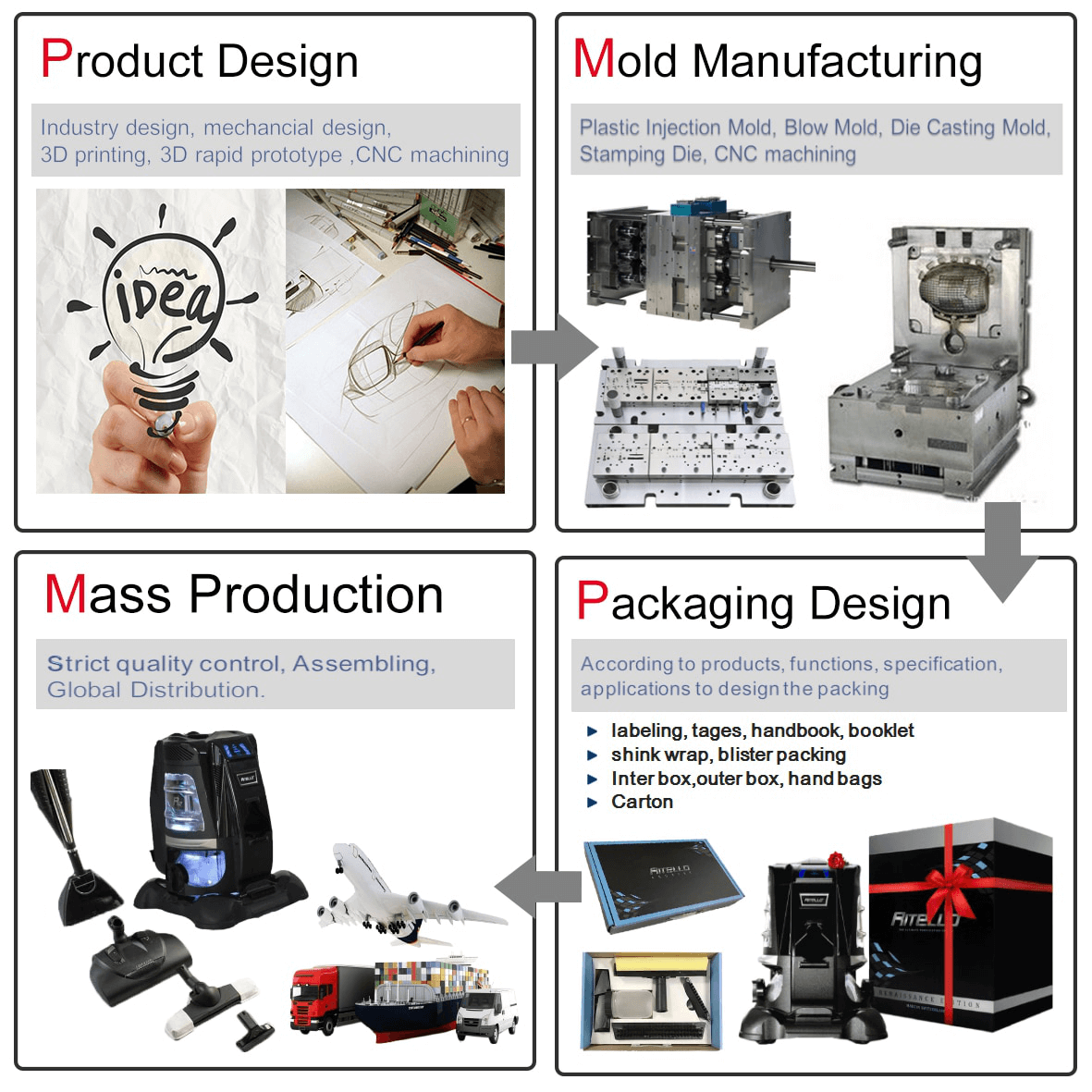

Accept the assignment The task of molding plastic parts is usually proposed by the designer of the part, and its content is as follows: 1. Drawings of conventionally produced parts that have been inspected and signed, and indicate the grade and transparency of the plastic. 2. Specifications or technical requirements of plastic parts. 3. Production […]

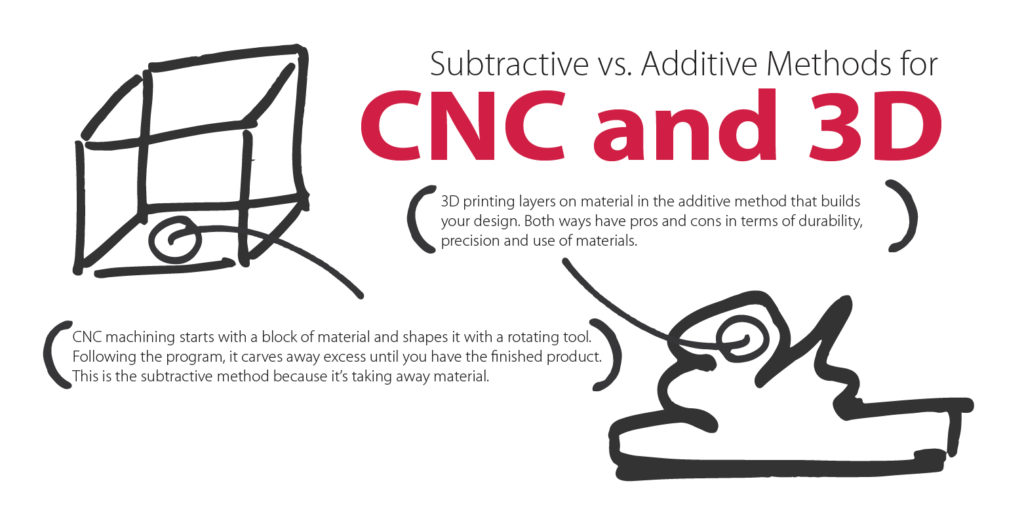

As technology advances and revolutionizes engineering and machinery, you want to know you’re using the best equipment and leading your business forward. Some of these advancements are in computer numeric control (CNC) machining and 3D printing. They both work with different materials. But which one is best for your needs? CNC machining and 3D printing […]

Electrical discharge machining (EDM) is a manufacturing process that implements electrical sparks to form a metal shape. Because of these sparks, EDM is also sometimes referred to as spark machining. In this process, the desired shape is cut from the metal when current discharges, or sparks, occur between two electrodes; where the sparking occurs, cuts […]

When a manufacturing business doesn’t have specific in-house CNC machining abilities, they’ll contract these tasks out to other companies to save money and time. Costs for in-house machining include expensive equipment, experienced workers, and space to house the new operation. In contrast, contract manufacturing can be done with the same level of quality and more […]