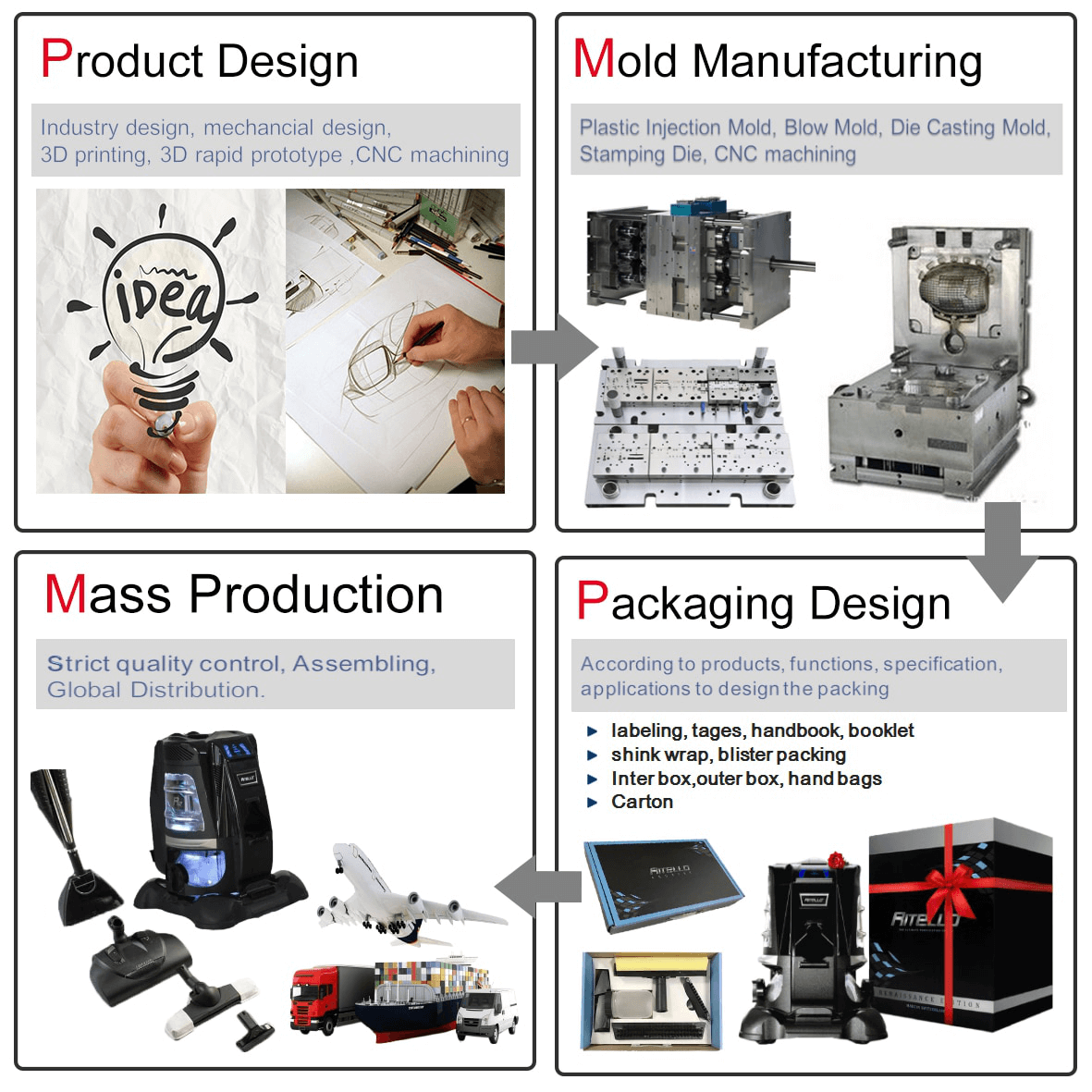

Injection Moulding Suppliers: Choose the Right Injection Molding Tools To create high-quality plastic parts injection moulding suppliers need to choose the right tools. After all, these tools play a vital role in ensuring the success of plastic parts. The suppliers have a wide range of option especially when it comes to injection tools. However, to […]

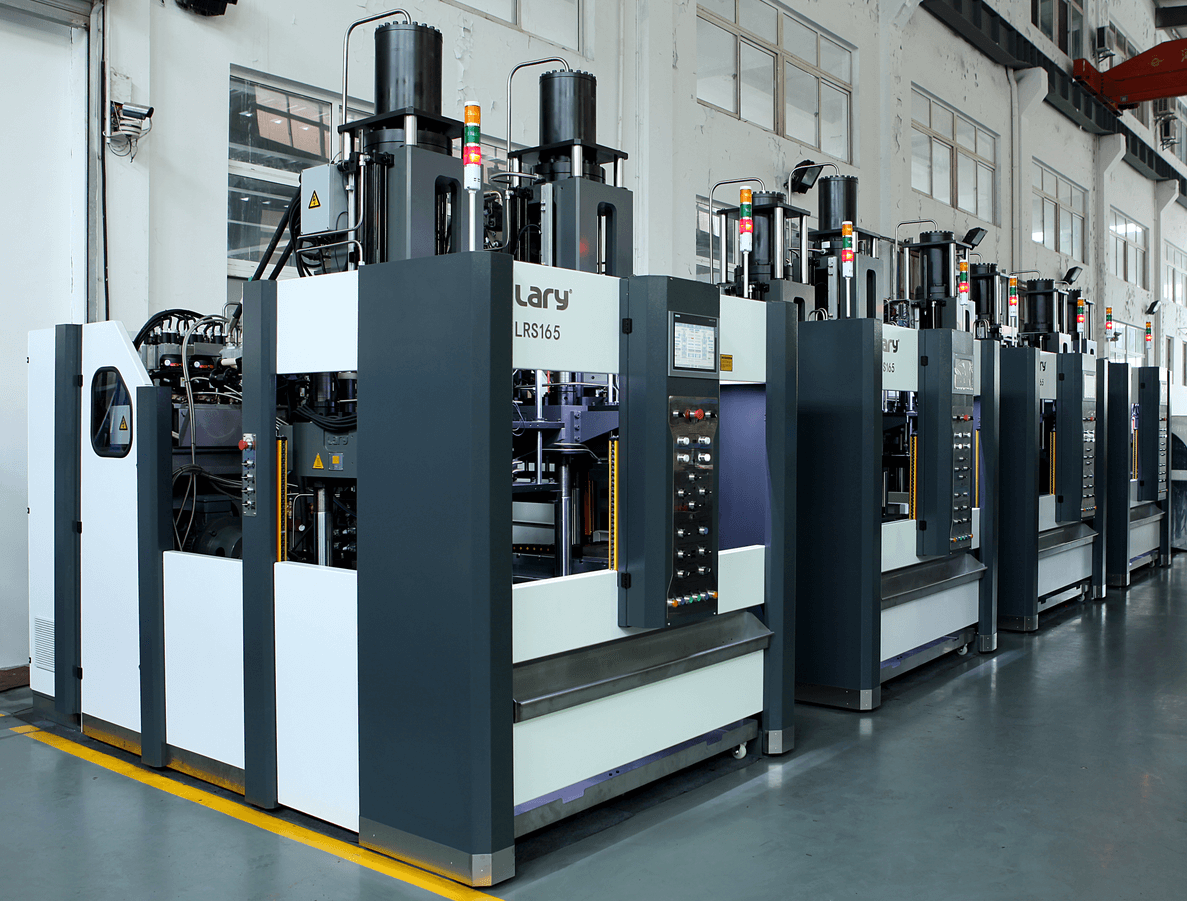

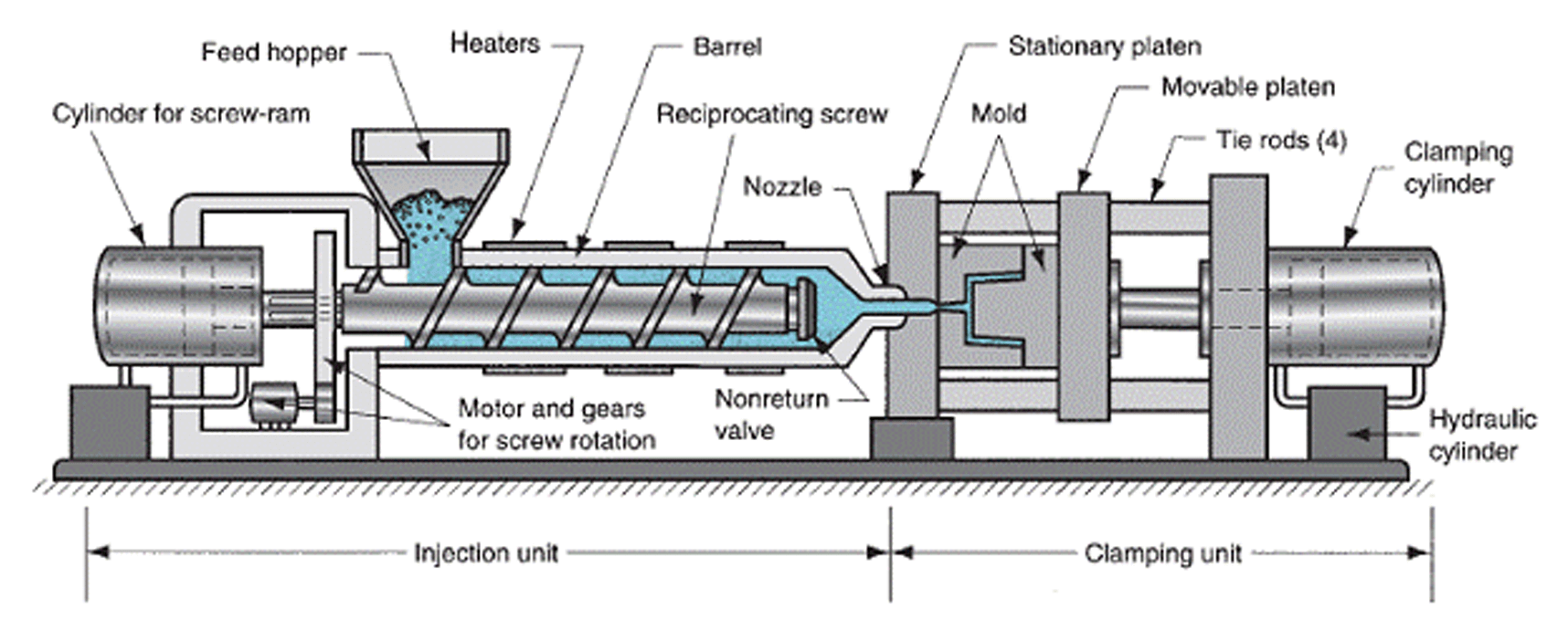

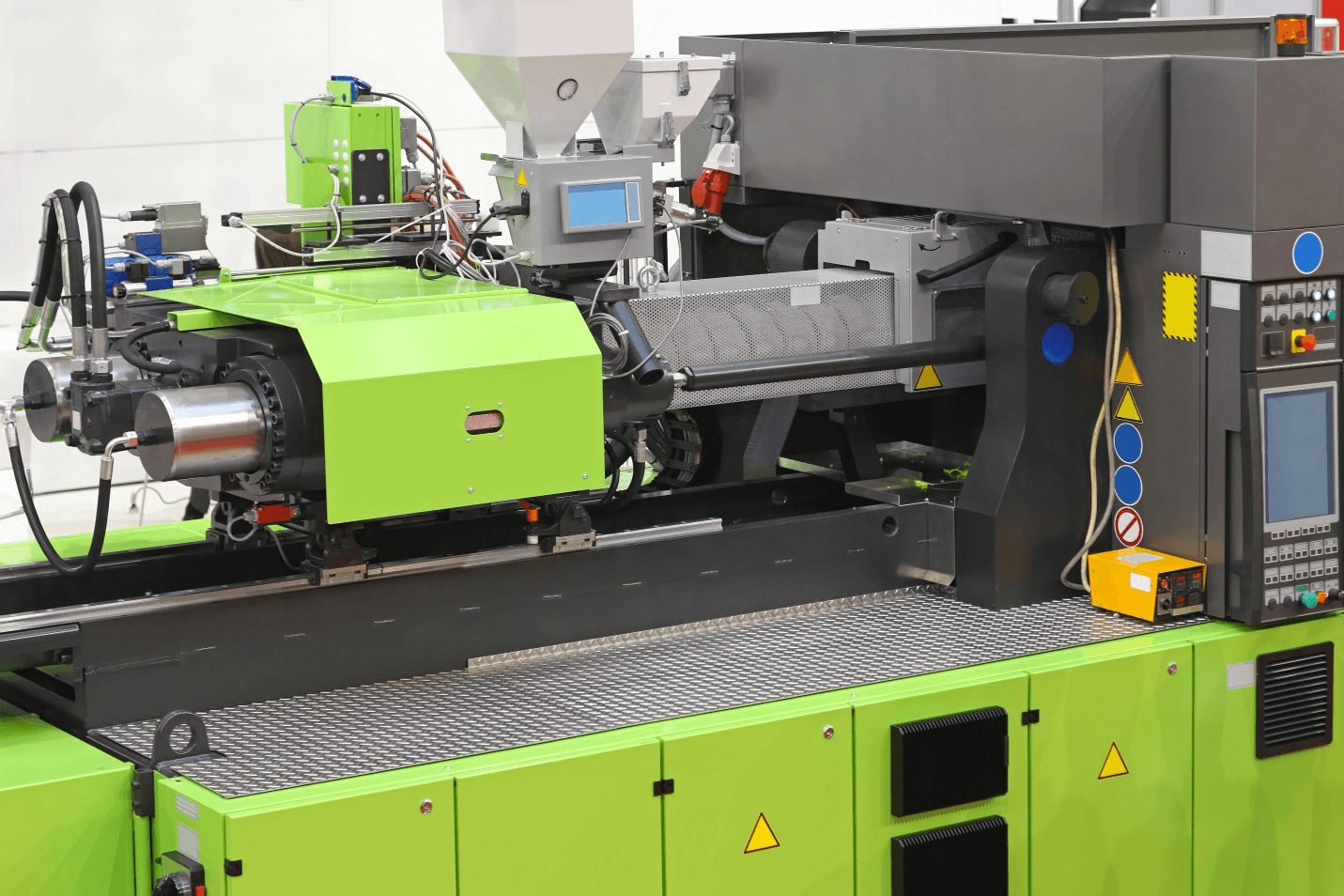

A Guide to Molding Machine for Plastic Molded Parts Manufacturer To ensure the right machinery size Plastic Molded Parts Manufacturer often turns towards Plastic injection molders. These injection molders have the experience and the expertise to determine the perfect machine size. After all, it is their objective to find the optimal size of the machine […]

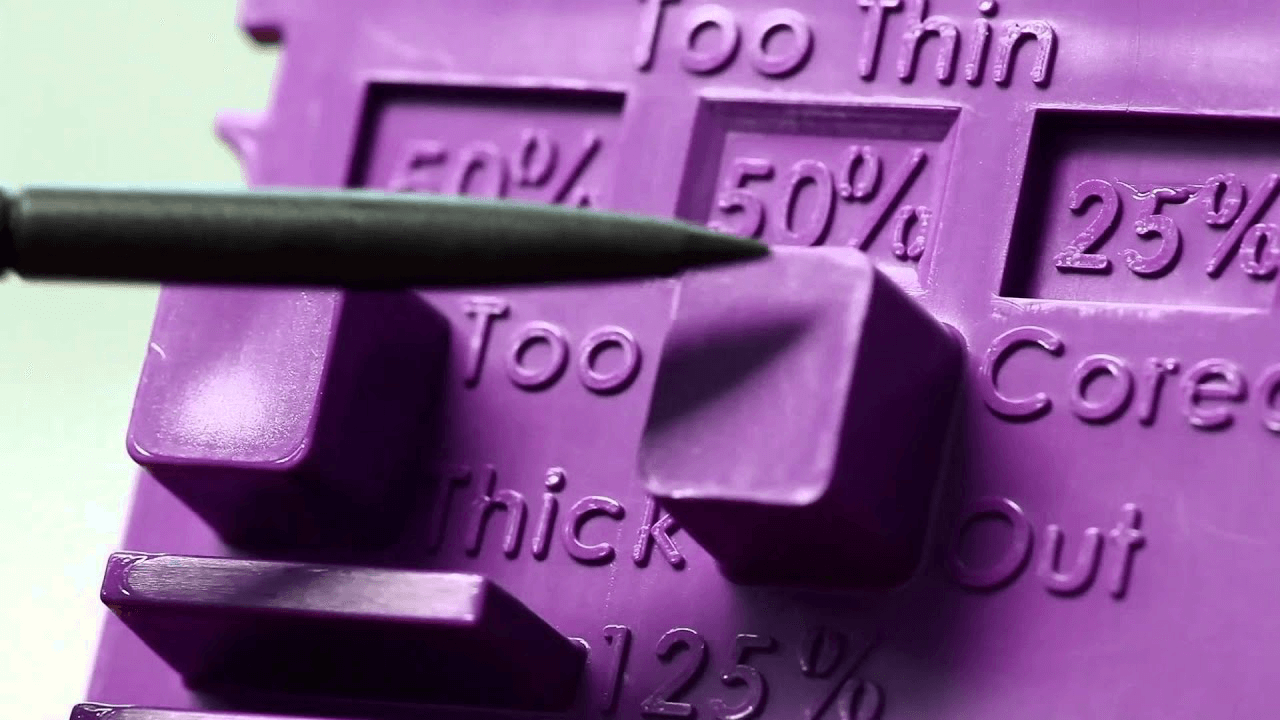

Top 10 Designing Tips for Plastic Injection Parts Manufacturer As a plastic injection parts manufacturer, you would have to primarily, focus on the design of parts and components. After all, the design plays a vital role in defining the success of the parts. The right design with the right execution would generate the right results. […]

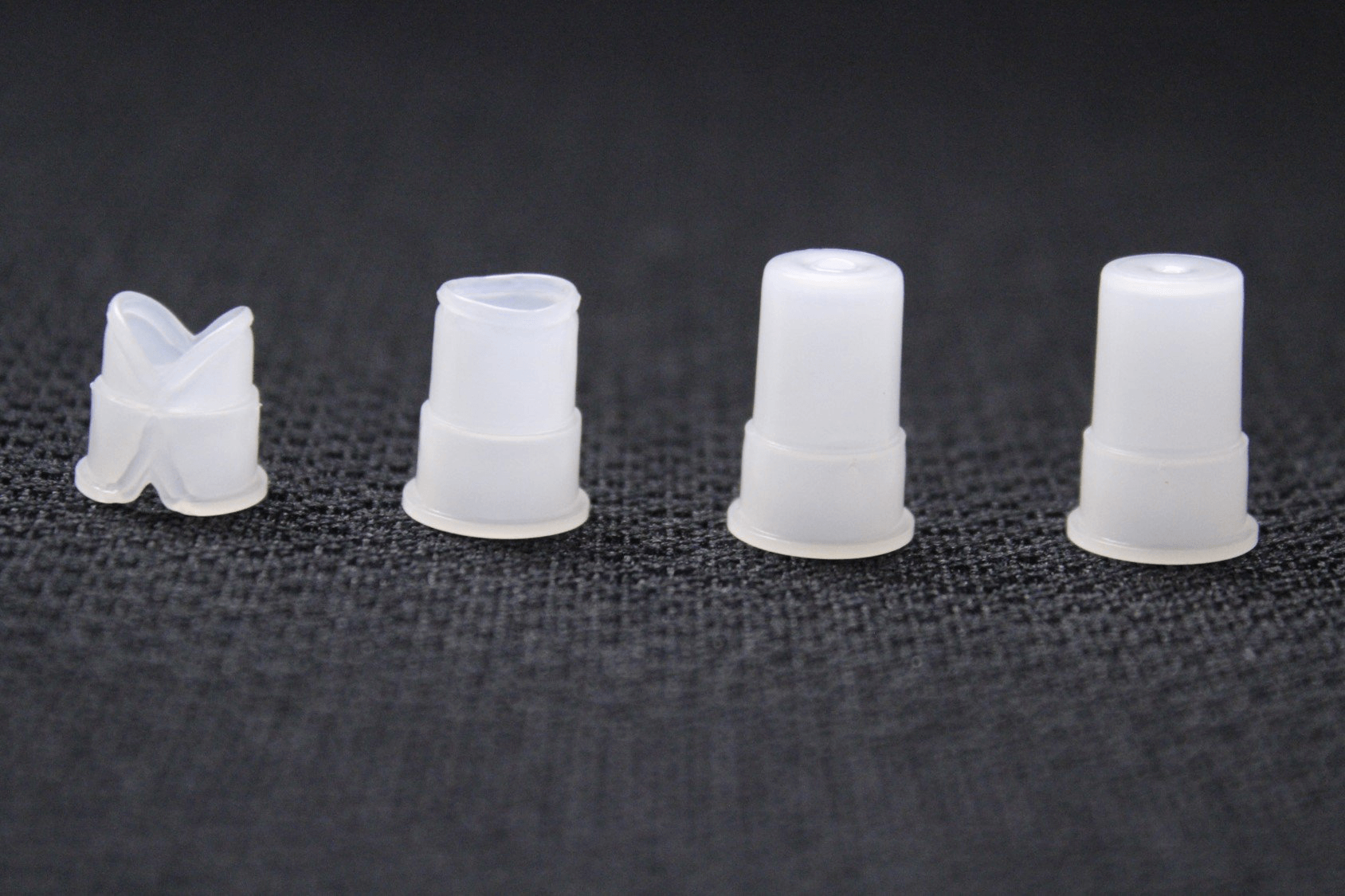

Plastic Injection Manufacturer: Injection Molding Defects and Causes Every plastic injection manufacturer aims to produce high quality, robust and reliable parts. After all, the quality of the product will have a direct impact on its brand name. To ensure high-quality products they use a series of techniques, implement the 5 M’s and spend time detecting […]

Plastic Die Mould Manufacturer: The 5 M’s – Part II We have already mentioned how the first two “Ms” – Mold and Man- have an impact on the productivity of a plastic die mould manufacturer. However, to excel the manufacturer needs to work on all the 5 M’s. It is important to understand that the […]

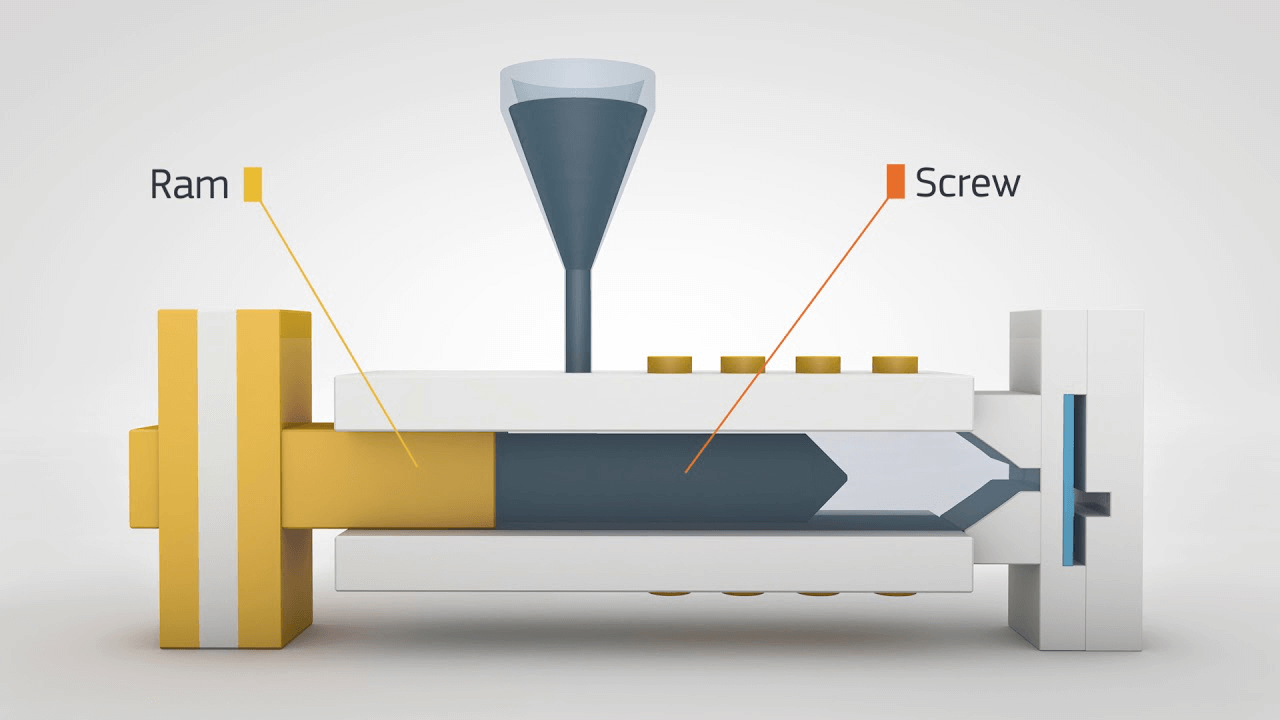

The 5 M’s of Injection Molding Manufacturers – Part I For smart injection molding manufacturers, the 5 Ms (Man, Material, Machines, Method & Metrics) carry great value. We understand many of you might not be familiar with these Ms. You might be thinking, how are they related to the molding industry. What do they refer […]

Injection Mold Manufacturers USA: Top 16 Benefits Injection Mold Manufacturers USA are benefiting from the continuous growth in the injection molding industry. The curve is going up and why should it not? After all, the industry offers endless benefits. Manufacturers and consumers around the globe are taking full advantage of injection molding techniques. They are […]

Injection Moulding Suppliers: The latest Market Trends Manufacturers have been reaching out to experienced and skilled Injection Moulding Suppliers to meet the rising demand for plastic parts. The injection moulding technique has been around for years. Technological advancement has led to advance and sophisticated injection moulding techniques. The Global market insight claims that industrial applications […]

What is Rapid Prototyping manufacturing? Types, Merits, and Application Rapid prototyping manufacturing is an excellent way to develop models using 3D CAD. In case, you are not familiar with CAD, it stands for computer-aided design. The manufacturers are able to fabricate models, physical parts and assembling seamlessly. You will use additive manufacturing to complete the […]

The mechanics of Injection Moulding Die Manufacturer Industries around the globe engaging injection moulding die manufacturer for mass production processes. After all, injection moulding is a reliable and efficient manufacturing process. It is excellent for the production of parts from the thermosetting plastic and thermoplastic materials. There has been an increase of 0.9% in the […]

Tips on Choosing the Right Injection moulding products manufacturers The injection moulding process is among the first choice for producing plastic parts. Due to advance features, durability and enhanced efficiency it is easy to make a decision. There are several manufacturing techniques. Thus, offering your versatility. Once you finalize your injection moulding technique, next comes […]

Precision hardware can be opened according to production needs. After that, some small parts can be cut by gongs or CNC processing. However, precision hardware must be opened for punching, and then welded, then sanded and sprayed. It’s done. It should be noted that the small parts also need to be plated or oil sprayed […]