Hersteller von Kunststoffformteilen: Unterschied zwischen Tiefziehen und Extrudieren

Hersteller von Kunststoffformteilen: Extrusionsformen gegen Thermoformen

Ein Hersteller von Kunststoffformteilen bietet Vielfalt in Bezug auf Formtechniken. Neben den gängigen Formmethoden wie Spritzguss und Rotation. Es gibt zwei effektivere Formtechniken, nämlich Thermoformen und Extrusionsformen.

Both of these techniques offer a number of benefits. They come with their advantages and disadvantages. Although, both techniques offer to end up moulding plastic, but the way they go about it is different. In this article, we are going to talk about the difference between these two techniques.

What a Plastic Molded Parts Manufacturer has to say about these techniques?

Having a basic understanding of both these techniques would help you make a better decision when it comes to choosing a plastic moulding method for your custom plastic parts.

Extrusion Molding

The process of extrusion molding is similar to that of injection molding. However, there is a slight difference, it tends to produce a long continuous shape. In addition, extrusion molding does not use a mold, on the contrary, it uses a die.

To make the parts, the technique squeezes hot raw material via a custom die. To make it easier for you to understand, we can say that it is like squeezing play Doh via a shaped hole. Unlike other molding techniques that put resins into a mould, extrusion puts it directly into the die shape.

So, here the die instead of the mold determines the shape of the desired product.

The Step by Step Process

Step 1: Raw plastic material including powder, pellets, granules are put into a hopper, later the material is shifted into an extruder. It is a hot long cylindrical chamber. To move the material through the chamber, it uses a revolving screw.

There are some extruders more than one revolving screw.

Step 2: There is a spinning screw operating, the raw material flows from the hoppers onto this spinning screw. For the operation of the spinning screw, it uses a horizontal barrel.

Step 3: Since every material has different properties, therefore the heating for every raw material is different. The temperature requirement of a certain material is taken into account. To form the desired shape, the molten plastic is passed through the die.

It is the small opening present at the end of the heated chamber.

Step 4: For the cooling purposes, the plastic extruded from the die is placed onto a conveyor belt. A plastic molded parts manufacturer can use either air or water for the cooling down purpose.

The process is similar to that of the injection molding. However, instead of the mould, here you would be using a die.

Step 5: It is important to design the die for every individual plastic profile. This would ensure the smooth flow of plastic from the cylindrical profile to the extruder. Thus, taking the final shape.

To ensure that the end product offers integrity, consistency in the flow is imperative.

Extrusion Moulding Common Use

If you want the parts to have a cross-sectional profile, use the extrusion moulding technique. For instance, PVC piping, hoses, and the straws. There is no need for the parts to be round. However, it is vital for them to have the same shape along the part’s length.

When you compare the cost of extrusion molding to other moulding process, you will realize that it is cost-efficient. Mainly because of the die and the machine are simple. They lack the complexity that is innate in molds and machines of other moulding processes.

Since it lacks complexity, thus it has its limitation. You can create only a number of products via this particular technique.

Best Uses of Extrusion Molding

You can design and manufacture parts that are simple and have a fixed cross-sectional profile. For instance, products are either have a circle shape and square.

Common Products

- Plastic Gutters

- PVC pipe

- Plastic Decking

- Straws and Hoses

Thermoforming

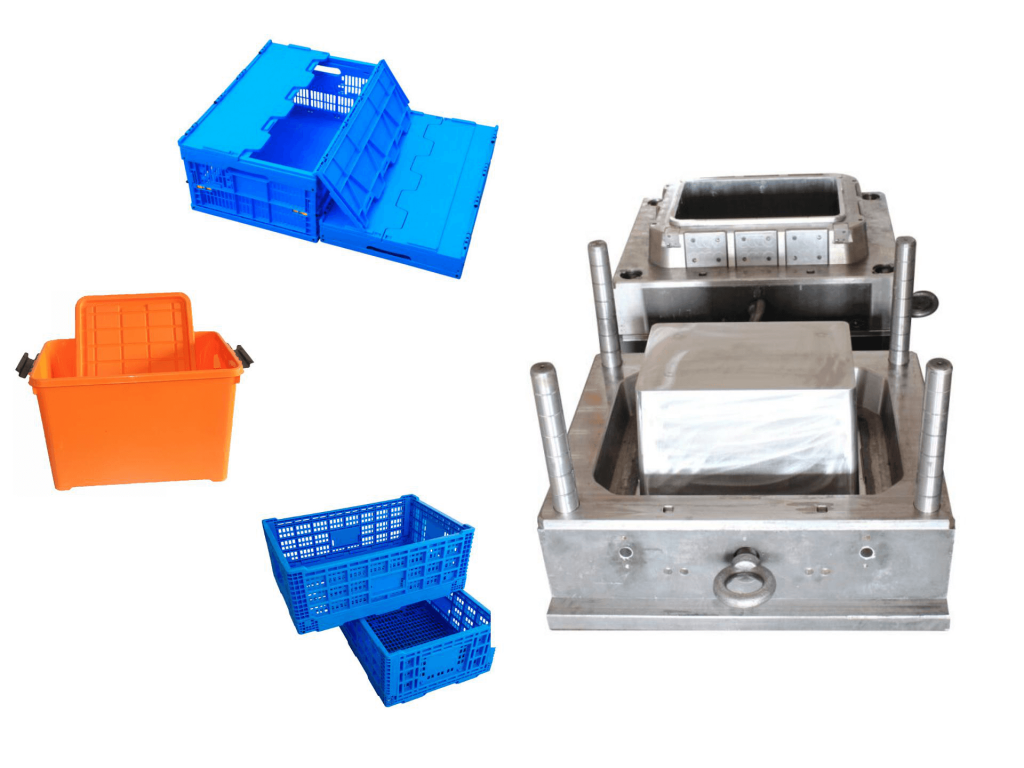

Thermoforming is an effective manufacturing process in which the sheet plastic – thermoplastic—is heated to forming temperature. The reason for doing so is to allow the sheet to form the specific shape in the mould.

It later is trimmed to create products. The great thing about thermoplastic sheets is that it comes in a wide range of materials, thickness, finishes, and colors.

To achieve the final product thermoforming does not reply to a certain type of process or a mould. On the contrary, it uses multiple molds along with the different processes to acquire the required shape. For 3D products, it is generally a single 3D mould.

Plastic Mould Parts Manufacturer uses aluminum for the creation of these 3D molds. Since the technique uses less pressure, therefore, it is possible to create parts or components at a lower rate.

Types of Thermoforming

There are two basic types of thermoforming: pressure forming and vacuum forming. Both techniques yield effective results, but there is a slight difference between the two.

Vacuum forming uses pressure and heat to draw the plastic into the respective shape. It first heats the sheet and then places it into the mould. To ensure that the plastic takes the final shape, it is manipulated using the vacuum.

Pressure forming, on the other hand, is similar to a vacuum. However, it has the additional benefit of pressure. With pressure, it is possible to achieve greater details and texture. Therefore, if you have to choose, between the two, pressure forming is the better choice.

Thermoforming Common Uses

Thermoforming, especially the tin-gauge is extremely popular for producing trays blisters, containers, disposable cups, clamshells, lids among other things. It is common among the food as we ass the general retail industry.

For something more sturdy and bigger, manufacturers go with the thick-gauge thermoforming. For instance, it is an effective technique for refrigerator liners, vehicle doors, utility vehicle beds, and dash panels.

Cost and Time of Production

The thermoforming may be an inexpensive plastic moulding technique; however, it does take time. On average, you would need around 8 weeks for the thermoform mold to be ready. After the mold is ready, production starts.

The manufacturing phase is faster. However, do bear in mind that the cost of the technique greatly depends upon the size of the part of the component. For instance, if you want to mold small size parts, it would cost you $20,000 a year.

Whereas, the same amount of parts with a bigger size would cost you $50,000 a year.

You can also check out our article on how to reduce cost per unit.

Plastic Molded Parts Manufacturer Offering the following benefits

Here are the benefits of both Thermoforming as well as the Extrusion molding technique.

Extrusion Molding Advantages

High speed, High Volume

Der Prozess ist kostengünstig, wenn Sie eine große Anzahl von Teilen oder Komponenten herstellen möchten. Es kann auch schnell Teile produzieren.

Kostengünstig

Wenn Sie das Extrusionsformen mit einer Reihe anderer Formtechniken wie Rotational vergleichen, werden Sie feststellen, dass es erschwinglich ist. Darüber hinaus kann die Anlage das übrig gebliebene Material wiederverwenden, wodurch nicht nur das Abfallergebnis, sondern auch die Kosten gesenkt werden.

Die Maschinerie ist robust, sie kann kontinuierlich arbeiten. Die Hersteller können eine Herstellungszeit von 24 Stunden am Tag genießen.

Flexibilität

Die Produkte haben einen gleichmäßigen Querschnitt; Es bietet jedoch erhebliche Flexibilität. Beim Extrusionsformen können Sie eine Reihe von Formen, Größen und Texturen genießen.

Vorteile des Tiefziehens

Anpassungsfähigkeit

Das Thermoformen bietet eine Reihe von Vorteilen, wobei die Anpassungsfähigkeit des Designs im Vordergrund steht. Die Technik bietet die Flexibilität, alle Anforderungen an das Verbraucherdesign zu berücksichtigen.

Schnelle Durchlaufzeit

Für die Vollproduktion dauert die Form natürlich einige Zeit. Im Fall des Prototyps kann er jedoch innerhalb kürzester Zeit effektive Ergebnisse liefern. Es bietet eine schnelle Bearbeitungszeit.

Materialoptimierung

Mit dem Thermoformen ist es möglich, Materialien zu optimieren, um niedrigere Werkzeugkosten sowie eine kostengünstige Herstellung sicherzustellen.

Darüber hinaus bietet die Technik eine Reihe weiterer Vorteile. Das Ergebnis ist eine sehr ästhetisch ansprechende Komponente oder ein Teil. Der Hersteller von Kunststoffformteilen bietet lackierbare Kunststoffe, farbige Kunststoffe sowie verschiedene andere Anpassungsmöglichkeiten an.