La importancia, las ventajas y los tipos de técnicas de fabricación de prototipos rápidos

¿Qué es la fabricación de prototipos rápidos? Tipos, méritos y aplicación

La fabricación rápida de prototipos es una forma excelente de desarrollar modelos utilizando CAD 3D. En caso de que no esté familiarizado con CAD, significa diseño asistido por computadora. Los fabricantes pueden fabricar modelos, piezas físicas y ensamblar sin problemas.

Utilizará la fabricación aditiva para completar la creación del modelo, las piezas y el ensamblaje. La gente generalmente se refiere a la fabricación aditiva como la impresión 3D. Hay diferentes tipos de prototipos. La alta fidelidad es cuando el prototipo se asemeja mucho al producto terminado.

En caso de que el prototipo no coincida con el producto final, es de Baja fidelidad. Hay varios otros tipos de creación rápida de prototipos. En este artículo, cubriremos la creación rápida de prototipos en detalle. Discutiremos su proceso de trabajo, importancia y aplicaciones.

Creación rápida de prototipos: un análisis en profundidad

La creación rápida de prototipos no se limita a un cierto tipo de tecnología de fabricación. Por el contrario, utiliza una amplia variedad de estas tecnologías. Sin embargo, la creación rápida de prototipos y la fabricación aditiva van de la mano.

Several RP technologies use a series of other techniques. For instance, they use moulding, casting and high-speed machining. Additive manufacturing is the manufacturer’s top priority. However, there are several other technologies available for the creation of the prototypes.

Below, we have listed the most conventional processes for creating prototypes.

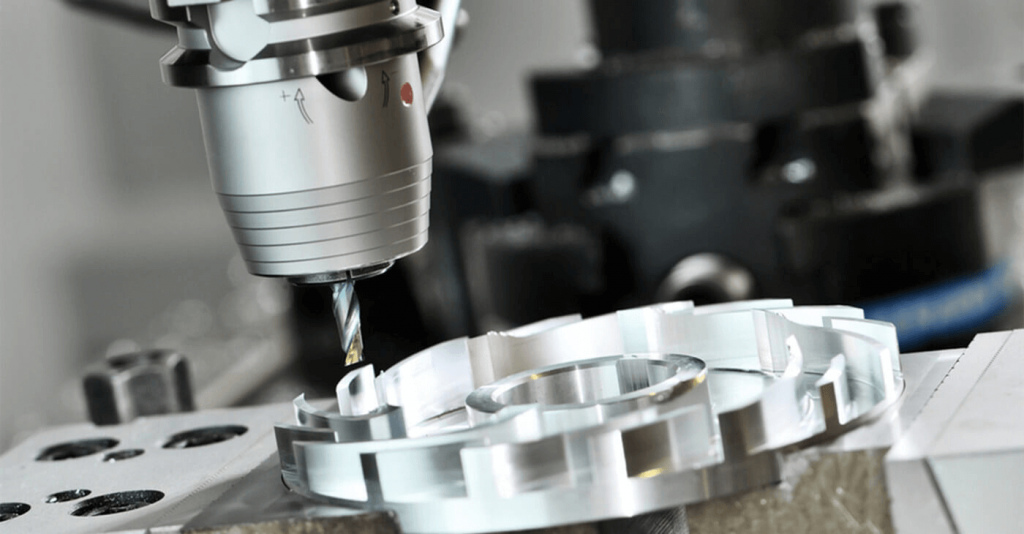

Subtractive: The technology uses turning, grinding and milling to produce the desired shape. It works on a block of material and carves it according to the requirements.

Compressive: This technique uses moulding, casting and compressive sintering. Instead of working on solid blocks and craving into shapes, it uses a different technique. It uses a liquid or semi-solid material. The technique forces the material into the respective shape. It then solidifies it.

Diferentes tipos de creación rápida de prototipos

Aunque la fabricación aditiva está ganando terreno, puede utilizar varios otros tipos. La implementación de la máquina de creación de prototipos depende de varios factores. Por ejemplo, el material que utiliza para la creación de prototipos juega un papel vital en la elección del método correcto.

Del mismo modo, también debe centrarse en el tipo de fabricación de prototipos rápidos . Estos 2, junto con otros factores, lo ayudarán a elegir el tipo correcto.

Fotopolimerización de tina (SLA)

La primera técnica exitosa para la impresión 3D comercial fue la fotopolimerización en tina. Fue eficiente y eficaz. Sigue siendo una opción popular entre los fabricantes. La buena noticia es que se encuentra entre las técnicas más asequibles.

The technique involves computer-controlled Ultra Violet light and photosensitive liquid. The UV light solidifies that liquid layer by layer.

Selective Laser Sintering

Selective Laser Sintering (SLS) is an effective technique. Manufacturers use it for both plastic and metal prototyping. The technique involves a laser and powdered material, sinter. SLS uses a laser to heat the material.

The prototype builds one layer at one time. However, the technique does not offer satisfying results. The final product’s surface is often rough and it requires additional work. In addition, the prototype lacks strength. It is weak in comparison to the ones you have using SLA.

Fused Deposition Modeling

FDM or more commonly referred, as the Material Jetting is another rapid prototype manufacturing technique. The technique is popular due to its affordability factor. You will find it mostly in non-industrial desktop printers.

The technique uses a spool of thermoplastic filament. Instead of craving the material, it first melts it within the printing nozzle barrel. The liquid plastic is then shaped layer by layer to attain the desired results.

The shaping takes place in accordance with a computer deposition program. Initially, the technique generated unsatisfying results. However, with time, it has become efficient and sophisticated. It no longer produces weak prototypes with poor resolution.

On the contrary, today you see more refined and robust prototypes. Despite offering better results, the process is still inexpensive. It is perhaps one of the most affordable rapid prototyping methods. Thus, it is perfect for product development.

Selective Laser Melting

The informal and more common name of Selective Laser Melting is Powder Bed Fusion. It is an excellent rapid prototyping technique. Manufacturers have been using this technique for a long time now. It is famous because it produces complex and robust prototypes.

It is perfect for making parts that are complex. In addition, these parts need high-strength. SLM is commonly seen in automotive, aerospace, medical industries, and defense. Thus, you can understand the type of services it caters to.

The technique uses a high electron beam or a high-powered laser. The laser or the beam melts a fine metal powder. It then uses the liquid power to build the product or the part layer by layer. You can use a number of materials as primary SLM material. Some of these materials include cobalt chrome alloys and stainless steel.

Likewise, you can also use aluminum and titanium. Aluminum is common mainly because it is affordable and readily available.

Laminated Object Manufacturing

Sheet Lamination is the common name. The process is very common among low-budget manufacturers. Although, it lacks SLS and SLM sophistication, but it does generate adequate results. In addition, it is cheaper than both of these techniques.

The process uses a series of thin laminates. A laser beam cuts these laminates according to specifications. Then, a CAD pattern design comes into action. This machine creates the prototype. The cutting devices form the prototype layer by layer.

The machine places every layer on top of the previous one. It securely bonds every layer to each other.

Digital Lighting Processing

DLP is similar to the SLA technique. However, it uses a more conventional light source. It uses polymerization of resins. The light source cures these resins. Although DLP is cheaper and faster in comparison to SLA, it requires additional support.

The DLP needs post building curing and it requires support structures.

Continuous Liquid Interface Production

CLIP is an alternative version of DLP. The technique does not use layers. It continuously pulls from the vat. In order to make the required cross-sectional pattern on plastic, the machine separates a part from the vat. It then makes the part cross a light barrier.

This barrier is responsible for changing the configuration. Thus, you acquire the desired shape.

Binder Jetting

Another famous rapid prototyping manufacturing technique is Binder Jetting. It is possible to print several parts at one time. Thus, the technique is efficient. The parallel printing feature increase efficiency. However, at the same time, it leads to a decrease in robustness.

The parts are weak in comparison to the ones produced using SLS. To make a part’s layer, Binder jetting uses nozzles spray and a powder bed. The nozzle let go of micro-fine droplets on the powder bed. These droplets help in bonding the powder particles to create a part’s layer.

Next is the compaction of every layer. It uses a roller for this purpose. For the next layer, it first lays the powder and then repeats the process. After the parts are ready, they might require oven treatment. After all, it is important to fuse the powder of the required parts and to burn off the binding agent.

Additive Manufacturing

A process builds products or parts using the deposition material and digital 3D design data. Due to its efficiency and effectiveness, the process is extremely popular.

The Impact of Rapid Prototyping on the Manufacturing Process

The above prototyping methods have the capacity to create an accurate model of products. Thus, the manufacturers, designers, and engineers would have a similar product to analyze. They would be able to access different aspects of the product.

They would be able to identify potential errors. Once, they are fully satisfied only then will they will go into the full production phase. There are several reasons manufacturers use prototyping. It is extremely helpful in evaluating a product’s aesthetic appeal, ergonomics, and manufacturing capability.

Different prototyping methods offer different benefits. For instance, the SLA printing technique is useful for testing precision parts. It can help identify potential errors and problems. If the manufacturer uses a photopolymer layer of 01.mm, it can produce accurate parts. These parts would effective take the place of the original product in tests.

It is possible to put the prototype through a load tolerance test, aerodynamic performance, stress tolerance test, and tension test. With the help of rapid prototyping manufacturing techniques, manufacturers save time.

It now takes less time to go from the designing phase to the production phase. It is possible to create an accurate prototype in no time. In addition, manufacturers do not have to pay a lot of money. The cost-efficiency is extremely profitable for the manufacturers.

Dado que es posible producir un prototipo en solo dos días, aumenta la eficiencia de fabricación del producto. Después de aprobar el prototipo, los fabricantes pueden pasar al proceso de producción.

Ahora pueden centrarse en configurar las herramientas y el proceso de fabricación en fábrica. Por lo tanto, disminuye el costo total de fabricación.

Beneficios de la fabricación rápida de prototipos para clientes y proveedores

No se puede negar el impacto de la creación rápida de prototipos en el proceso de fabricación. También hay varios beneficios. Hablaremos de estos beneficios más adelante. Sin embargo, por ahora, nos centraremos en cómo la creación rápida de prototipos es beneficiosa para proveedores y clientes.

Los proveedores pueden estimar mejor la producción y el tiempo de costo utilizando estos prototipos. Si un determinado prototipo tarda unos 2 días, podrían calcular el tiempo exacto necesario para crear el producto original.

Además, los proveedores pueden crear fundición de metal utilizando los prototipos SLA. También pueden usarlos como patrones maestros. Por lo tanto, el tiempo necesario para establecer una fábrica y su herramienta disminuye significativamente.

Por otro lado, ofrece una serie de beneficios a los consumidores. El cliente puede ver físicamente y sostener su producto final. Les darían una mejor idea de cómo se vería y se sentiría el producto.

Además, aumentaría su confianza. En caso de que haya algún problema, con el prototipo, pueden señalarlo. Esto ayudará a eliminar el problema en la fase de producción final. Asimismo, les ayudará a ahorrar en el proceso de diseño y fabricación.

Beneficios de la creación rápida de prototipos en el desarrollo y la fabricación de productos

La creación rápida de prototipos ofrece una serie de beneficios. A continuación, enumeramos algunos de estos beneficios.

Rentable

Simplemente no podemos negar el hecho de que la creación rápida de prototipos es rentable. Además, también es más rápido en comparación con la construcción de un modelo a gran escala. Los fabricantes pueden crear prototipos de alta precisión utilizando técnicas modernas de creación de prototipos.

Por lo tanto, ahorran mucho, ya que los prototipos son extremadamente más baratos de crear que el producto original.

Tiempo eficiente

In addition to being cost-efficient, rapid prototyping is also very time efficient. It reduces the time manufacturers need to develop special tools and molds. The prototype will help you generate the right kind of tools and molds.

Minimizes Waste

Another great thing about rapid prototyping is that it has the ability to minimize waste. Unlike, creating a real testing product, prototypes require a minimal amount of raw material. You would use only that material that is required for prototyping.

Complex creating

The modern and sophisticated rapid prototyping technology can help you create marts of minuscule size. Similarly, it is possible to create prototypes of products that require complex geometries.

Three Dimensional Designs

A diferencia de la imagen 2-D en una computadora, la creación de prototipos ofrece un producto 3D. Los fabricantes y consumidores pueden tocar y sentir el producto. Pueden analizarlo a fondo antes de pasar a la fase de producción.

Error de identificación

La creación rápida de prototipos y la fabricación aditiva tienen mucho que ofrecer. Es posible identificar los posibles problemas y errores de un producto a través de un prototipo. El fabricante no tendría que asumir el costo total de producir un producto en caso de una falla en el producto final.

Personalización

Con la creación y fabricación de prototipos rápidos, la personalización se vuelve fácil. El cliente y el fabricante pueden realizar todos los cambios deseados. Hacen un cambio en el diseño sin pasar por la molestia de cambiar todo el proceso.

Pruebas más fáciles

Another advantage of prototyping is that it offers the ease of testing. The manufacturers no longer have to spend a great amount of testing. They need to focus on the prototype. After all, the properties of the prototype material are quite similar to that of the final product.

No need for Feedback

It is possible to make changes instantly. If there seems an error, the manufacturers can remove it. Thus, there is no need for them to wait for feedback before making any changes.

How to Choose a Prototyping technique?

Several factors contribute to making this decision. Below, we did list some of these factors.

Production of Volume

First and foremost, the manufacturer needs to understand the production volume. There are certain prototyping techniques that work well with smaller production volumes.

Speed of Production

Another factor that has a direct influence on the type of prototyping technique you choose is the speed of production. You need to know the amount of time you have before you deliver the final product. Some prototyping techniques require just 2 days to create a prototype.

On the other hand, certain techniques would require more time. In case, you can are in a hurry, you can go with techniques that require less time for creating an accurate prototype.

Financial Considerations

Of course, the amount of money you are willing to invest makes a lot of difference. Some techniques are expensive in comparison to others. For instance, Fused Deposition Modeling is less expensive than SLS.

Geometry of Parts

The complexity of the prototype has a great impact on the rapid prototyping technique. For example, Selective Laser Melting is the perfect technique to design and develop complex prototypes. It generates prototypes that are robust.

Intended use of Product or Parts

This is another important factor to consider. The manufacturer needs to pay heed to where the final products are to be used.

Rapid Prototyping and Manufacturing Services to Support your Product

Prototype development is an important factor that helps in determining the viability of the product or apart. However, it may not be a practical solution from an operational and coastal perspective. Fortunately, Katio Mould manufacturers offer state of the art technology.

They use technologies like CAD and CAM software to alleviate any concerns of their respective clients. In addition, they make it possible for clients to join hands with their experts. Thus, fulfilling the needs of single-unit production.

How much does it cost?

The cost of rápidos de creación de prototipos depends upon a number of factors including the size, shape, and volume of the parts. In addition, the material, the surface finish, and the amount of post-manufacturer processing contribute to the overall cost.

Nuestros servicios

Katio Mould is among the leading prototyping companies. It has world-leading expertise and experience in rapid prototyping manufacturing techniques and additive manufacturing processes. With our expert designers, the end-users will be able to enjoy an accurate prototype of their product.

Si podemos ayudarlo con su proyecto, llámenos al 0086-769-82821468 o envíe un .