Combien coûtent les pièces de voiture d'usinage CNC? (machine cnc pour l'industrie automobile)

Combien coûtent les pièces d'usinage CNC? (Machine CNC pour l'industrie automobile)

Fabrication de pièces de voiture d'usinage CNC à partir de métal

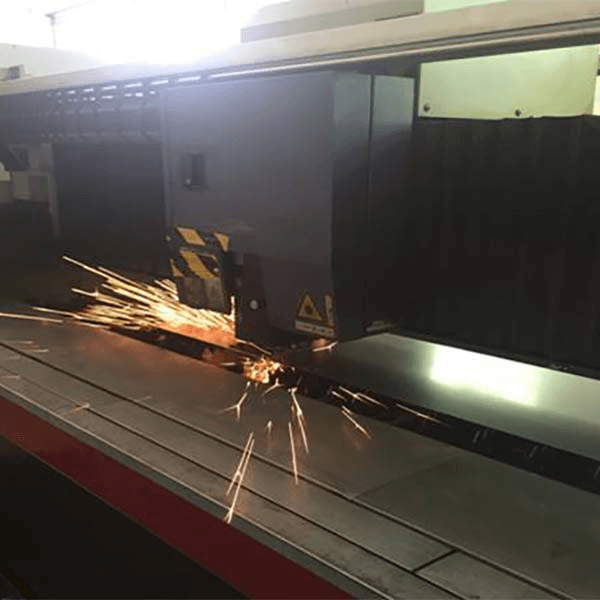

Lors de la fabrication de Pièces de voiture d'usinage CNC usinage CNC en utilisant le fraisage, les machines CNC aideront à obtenir des pièces de haute qualité. Et cela réduit considérablement leur coût. La fabrication de pièces de rechange en métal sur des équipements innovants vous permet d'obtenir des pièces géométriquement parfaites. Le fraisage sur des machines CNC peut même remplacer le meulage de produits.

Working with metal using milling is becoming an indispensable element in many areas of human activity. Thus, metalworking using CNC machines allows us to fulfill orders for the advertising industry, in particular, the production of outdoor advertising. So, the production of spare parts, clichés or stamps, engraving on various surfaces come with a high level of image accuracy at high speed.

In the case of the manufacture of spare parts from metal, the batch size does not matter. Hence, automation can handle any number of parts with ease.

What is important for Cnc Machining Car Parts?

What is important – milling or turning Pièces de voiture d'usinage CNC on CNC machines allows you to reduce the percentage of defective parts to a minimum. The positive point is that the equipment is capable of working day and night without fatigue and sickness.

The process of manufacturing Cnc Machining Car Parts

- Study of the parameters and features of the manufactured part.

- Selection of the appropriate tool and workpiece.

- Drawing up a program according to the customer’s drawing. Moreover, taking into account the processing features for a specific metal grade and the specifics of the part.

- Programming and writing the converted data to the medium of the machine.

- Manufacturing of products in an automated mode. Similarly, we transmit special commands are to electronic controllers. The control system, using sensors monitors the execution of each command from the beginning to the end of the manufacturing process.

To write control programs, first create a 3D model in a CAD editor following cad programs are popular:

- AutoCAD

- CorelDRAW

- Rhinoceros 3D

- SolidWorks, etc.

Then import it into a CAM editor, where the control programs itself. The machine without human intervention accurately performs the following tasks:

- adjusts the number of revolutions;

- adjusts the amount of feed;

- Controls all parameters to obtain the specified shape and size of the part.

Thanks to this, the Cnc Machining Car Parts manufacturing process go by:

- low labor intensity

- high productivity

- maximum accuracy and compliance of finished parts with requirements without defects

- optimal repeatability in mass production of products

- low cost of parts for large-scale production

- excluding human error

CNC EQUIPMENT FOR MAKING CUSTOM PARTS

For the production of parts on CNC, imported equipment with numerical control is very common. Kaitomould have all the necessary capacities and capabilities necessary for the implementation of small orders and large-scale production. Moreover, our manufacturing platform can supply high quality metal parts at the best price. And the whole process can be possible in the shortest possible time.

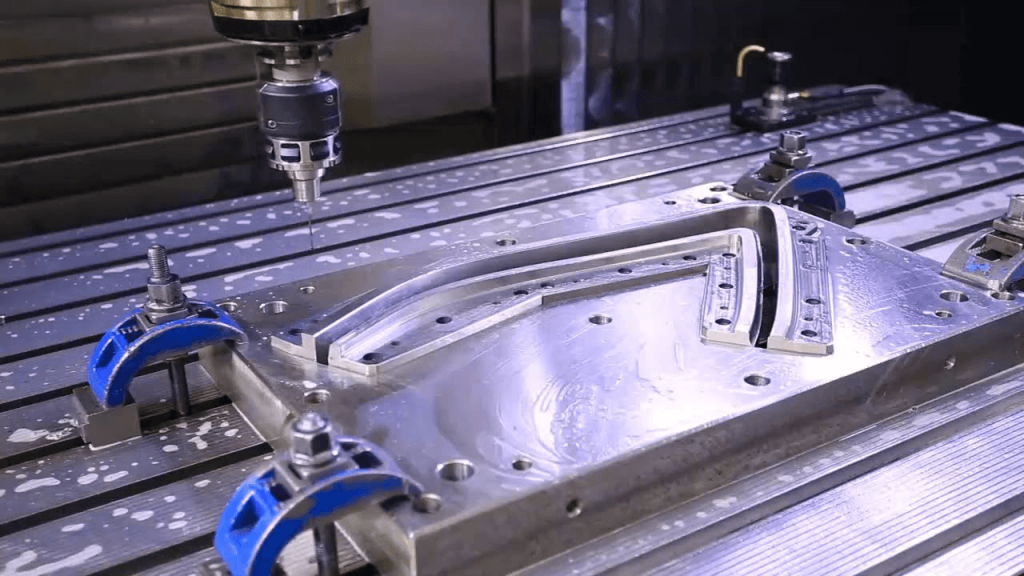

HORIZONTAL CONSOLE-TYPE MILLING MACHINE WITH CNC XK6040

Used to process:

- complex surfaces;

- matrices;

- molds;

- Parts for the engineering industry.

Similarly, it can perform the following types of work:

- fraisage

- forage

- ennuyeuse

En raison du mouvement accéléré de la table de travail dans toutes les directions, le traitement des produits se produit avec une productivité élevée. Convient pour le fraisage de pièces en acier, fonte et métaux non ferreux.

Pourquoi l'usinage CNC est-il si populaire?

Récemment, les tours à commande numérique se sont généralisés. Souvent, lorsque le profil de travail change ou que de nouveaux produits apparaissent dans le processus de production, il est nécessaire de modifier les programmes pour les tours. Si votre entreprise ne dispose pas d'un spécialiste capable de faire face à une telle tâche, nous sommes heureux de vous proposer les services de nos partenaires pour le développement de programmes pour tours CNC.

Manufacturing Pièces de voiture d'usinage CNC is very common everywhere. In addition, you can order this service from our company. New equipment periodically comes to production and labor methods are constantly improving. Even such a delicate matter as turning is increasingly moving towards automation.

At the moment, at enterprises whose functions include the manufacture of spare parts, machine tools with program control are widely famous. Innovative technologies can significantly save time and guarantee material processing accuracy and high quality.

A huge advantage of CNC machines is their reprogramming capability. Subsequently, it does not take much time and allows for custom-made spare parts.

Spare parts with a multi-stage or curved surface are more expedient to produce on CNC lathes. Such technologies make it possible to produce a large number of high quality spare parts in a short time.

Recently, there has been a tendency to introduce an end-to-end production process, which will fully automate all stages of parts manufacturing. With the use of CNC machine tools, metalworking is accelerated at least twice.

Manufacturing of spare parts according to drawings

As mentioned above, CNC machines can produce Pièces de voiture d'usinage CNC even on an individual order, regardless of the amount of work. In order to order the manufacture of spare parts according to drawings, you must provide the company with a drawing of the required part.

Furthermore, a drawing in any production is the main document for accepting an order. The drawing should contain all the details of the order – the material, its physical characteristics and various specific nuances.

If it is necessary to produce an exclusive spare part, the part comes under testing to meet all the requirements stated in the order. In case of inaccuracies, the drawings are corrected and the production should be perfect.

The choice of production method depends on the:

- type

- size and

- configuration of the part

The manufacture of spare parts requires compliance with all stages of production. So, the next step is to draw up a plan according to which the part requires development.

Il convient de garder à l'esprit qu'il est plus rentable de fabriquer de grandes quantités de Pièces de voiture d'usinage CNC . Lorsque vous produisez des pièces de rechange sur des machines CNC, vous pouvez compter sur l'identité de toutes les pièces d'un lot entre elles.

Quel est le coût des pièces de voiture d'usinage CNC?

Le coût total et le temps de fabrication des pièces sur commande à l'aide de machines à commande numérique viennent après prise en compte des coûts suivants:

- matériel (marque, épaisseur, etc.) requis pour le travail;

- Complexité et dimensions du produit, dont dépendent la création de programmes de contrôle et le réglage des machines CNC;

- Le nombre total d'unités de produit dans la commande;

- La nécessité d'une finition supplémentaire selon le cahier des charges (ponçage, revêtement, polissage, etc.).

Fraisage dans l'industrie automobile

L'industrie automobile moderne utilise les dernières technologies et matériaux pour l' Pièces de voiture d'usinage CNC . Par conséquent, il comprend les métaux et alliages, les céramiques, les composites et les plastiques.

Avec la concurrence croissante, les exigences en matière de nœuds et de pièces automobiles sont élevées. Une proportion croissante de pièces automobiles se développe en utilisant des technologies qui n'étaient auparavant disponibles que pour les industries aéronautique et spatiale.

Par exemple, de nombreuses pièces d'une voiture ou d'un camion ont une forme volumétrique complexe. Mais en même temps, ils doivent être précis. De plus, ils doivent présenter des erreurs minimales et un traitement de surface de haute qualité.

Diverses méthodes mécaniques sont utilisées pour traiter ces pièces et assemblages, y compris le fraisage. De plus, certaines pièces ne peuvent pas être utilisées avec des machines CNC sans fraisage.

Pourquoi des pièces de voiture d'usinage CNC pour votre voiture?

Generally, the heart of any car is its engine. In addition, the performance, resource and reliability of the car depend on how accurately. And it also depends on with high quality the heart of the car.

For example, without milling, it is impossible to make such important parts of a machine engine as the head and cylinder block. It is easy and simple to make these parts by milling on a computer numerical control (CNC) machine.

Processing of materials by cutting, with some varieties of which you are familiar with (turning, drilling, milling, planning, etc.), is uneconomical. Because it carries by significant waste of materials in the form of chips. In addition, many modern materials with high hardness are difficult to cut. There are also limitations on machining accuracy.

The widespread use of Pièces de voiture d'usinage CNC has become possible due to the mass, serial and single-piece production. Subsequently, there are many reasons for this.

Conclusion

The main feature of C Cnc Machining Car Parts equipment is that information about a given law of motion of its controlled elements.

The use of CNC machines makes it possible to qualitatively change technological processes in mechanical engineering. Moreover, it improves the culture of production, reduce production areas, and eliminate the influence of subjective factors on product quality. In addition, it reduces production time, use a production strategy “just in time” and, as a result, achieve a large economic effect.

If you are looking for professional cnc machining company in china, we can help you. We manufacture perfect materials for car parts.