Сколько стоит обработка автомобильных запчастей с ЧПУ? (станок с чпу для автомобильной промышленности)

Сколько стоят автозапчасти с ЧПУ? (Станок с ЧПУ для автомобильной промышленности)

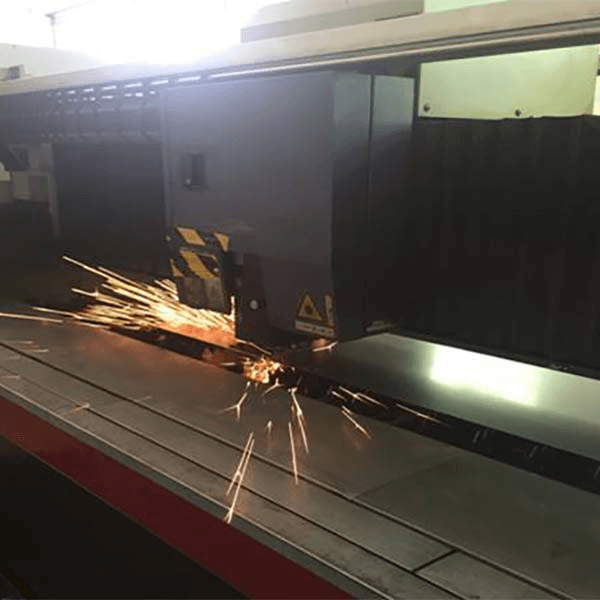

Производство деталей автомобилей с ЧПУ из металла

При изготовлении Обработка автомобильных запчастей с ЧПУ с ЧПУ с помощью фрезерования станки с ЧПУ помогут получить детали высокого качества. И это значительно снижает их стоимость. Изготовление запчастей из металла на инновационном оборудовании позволяет получать геометрически идеальные детали. Фрезерование на станках с ЧПУ может заменить даже шлифовку изделий.

Работа с металлом методом фрезерования становится незаменимым элементом во многих сферах деятельности человека. Таким образом, обработка металла на станках с ЧПУ позволяет нам выполнять заказы для рекламной индустрии, в частности, для изготовления наружной рекламы. Так, изготовление запчастей, клише или штампов, гравировка на различных поверхностях идет с высокой точностью изображения на высокой скорости.

В случае изготовления запчастей из металла размер партии значения не имеет. Следовательно, автоматизация может легко обрабатывать любое количество деталей.

Что важно для обработки автомобильных деталей с ЧПУ?

Что немаловажно - фрезерная или токарная Обработка автомобильных запчастей с ЧПУ с ЧПУ на станках с ЧПУ позволяет снизить процент бракованных деталей до минимума. Положительным моментом является то, что техника способна работать днем и ночью без усталости и болезней.

Процесс производства автомобильных запчастей с ЧПУ

- Изучение параметров и особенностей изготавливаемой детали.

- Подбор подходящего инструмента и заготовки.

- Составление программы по чертежу заказчика. Причем с учетом особенностей обработки под конкретную марку металла и специфики детали.

- Программирование и запись преобразованных данных на носитель машины.

- Manufacturing of products in an automated mode. Similarly, we transmit special commands are to electronic controllers. The control system, using sensors monitors the execution of each command from the beginning to the end of the manufacturing process.

To write control programs, first create a 3D model in a CAD editor following cad programs are popular:

- AutoCAD

- CorelDRAW

- Rhinoceros 3D

- SolidWorks, etc.

Then import it into a CAM editor, where the control programs itself. The machine without human intervention accurately performs the following tasks:

- adjusts the number of revolutions;

- adjusts the amount of feed;

- Controls all parameters to obtain the specified shape and size of the part.

Thanks to this, the Cnc Machining Car Parts manufacturing process go by:

- low labor intensity

- высокая производительность

- максимальная точность и соответствие готовых деталей требованиям без дефектов

- оптимальная повторяемость при массовом производстве продукции

- низкая стоимость деталей для крупносерийного производства

- исключая человеческую ошибку

ОБОРУДОВАНИЕ С ЧПУ ДЛЯ ИЗГОТОВЛЕНИЯ ДЕТАЛЕЙ НА ЗАКАЗ

Для производства деталей на ЧПУ очень распространено импортное оборудование с числовым программным управлением. Кайтом иметь все необходимые мощности и возможности, необходимые для выполнения небольших заказов и крупносерийного производства. Кроме того, наша производственная площадка может поставлять высококачественные металлические детали по лучшей цене. И весь процесс возможен в кратчайшие сроки.

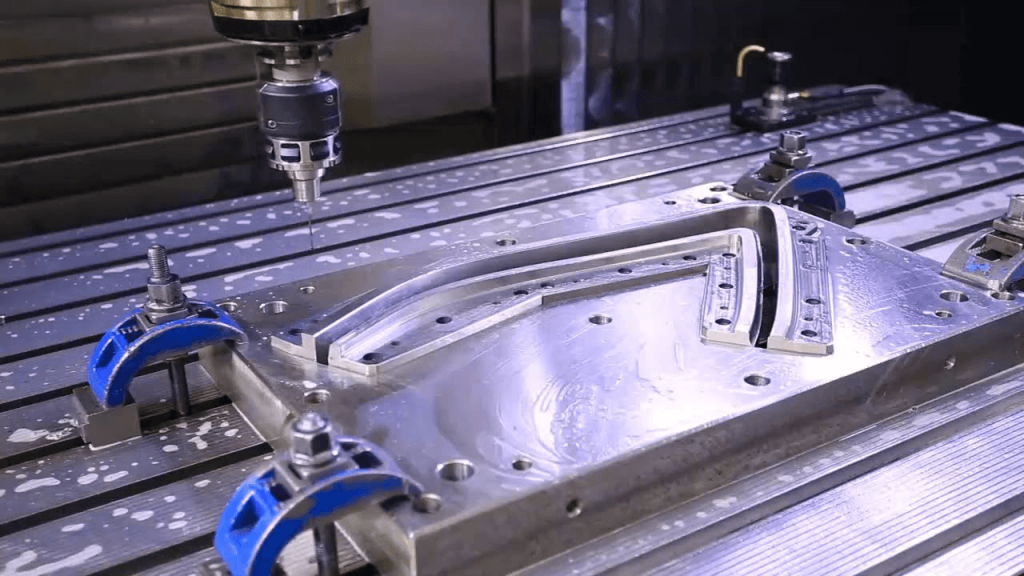

ГОРИЗОНТАЛЬНЫЙ КОНСОЛЬНЫЙ ФРЕЗЕРНЫЙ СТАНОК С ЧПУ XK6040

Используется для обработки:

- сложные поверхности;

- матрицы;

- формы;

- Запчасти для машиностроения.

Аналогичным образом он может выполнять следующие виды работ:

- milling

- drilling

- boring

Due to the accelerated movement of the working table in all directions, the processing of products occurs with high productivity. Suitable for milling workpieces made of steel, cast iron and non-ferrous metals.

Why cnc machining is so popular?

Recently, numerically controlled lathes have become widespread. Often, when the work profile changes or new products appear in the production process, it is necessary to change the programs for lathes. If your company does not have a specialist who can cope with such a task, we are pleased to offer you the services of our partners for the development of programs for CNC lathes.

Производство Обработка автомобильных запчастей с ЧПУ is very common everywhere. In addition, you can order this service from our company. New equipment periodically comes to production and labor methods are constantly improving. Even such a delicate matter as turning is increasingly moving towards automation.

At the moment, at enterprises whose functions include the manufacture of spare parts, machine tools with program control are widely famous. Innovative technologies can significantly save time and guarantee material processing accuracy and high quality.

A huge advantage of CNC machines is their reprogramming capability. Subsequently, it does not take much time and allows for custom-made spare parts.

Spare parts with a multi-stage or curved surface are more expedient to produce on CNC lathes. Such technologies make it possible to produce a large number of high quality spare parts in a short time.

Recently, there has been a tendency to introduce an end-to-end production process, which will fully automate all stages of parts manufacturing. With the use of CNC machine tools, metalworking is accelerated at least twice.

Manufacturing of spare parts according to drawings

As mentioned above, CNC machines can produce Обработка автомобильных запчастей с ЧПУ even on an individual order, regardless of the amount of work. In order to order the manufacture of spare parts according to drawings, you must provide the company with a drawing of the required part.

Furthermore, a drawing in any production is the main document for accepting an order. The drawing should contain all the details of the order – the material, its physical characteristics and various specific nuances.

If it is necessary to produce an exclusive spare part, the part comes under testing to meet all the requirements stated in the order. In case of inaccuracies, the drawings are corrected and the production should be perfect.

The choice of production method depends on the:

- type

- размер и

- configuration of the part

The manufacture of spare parts requires compliance with all stages of production. So, the next step is to draw up a plan according to which the part requires development.

It should be in mind that it is more profitable to manufacture large quantities of Обработка автомобильных запчастей с ЧПУ. When producing spare parts on CNC machines, you can count on the identity of all parts of any batch to each other.

What is the cost of Cnc Machining Car Parts?

The total cost and time of manufacturing parts to order using CNC machines come after taking into account the following costs:

- material (brand, thickness, etc.) required for work;

- Complexity and dimensions of the product, on which the creation of control programs and the adjustment of CNC machines depend;

- The total number of product units in the order;

- The need for additional finishing according to the specification (sanding, coating, polishing, etc.).

Milling in the automotive industry

The modern automotive industry uses the latest technologies and materials for Обработка автомобильных запчастей с ЧПУ. Hence, it includes metals and alloys, ceramics, composites and plastics.

With increasing competition, the requirements for nodes and car parts are going high. An increasing proportion of car parts are developing using technologies that were previously available only to the aircraft and space industries.

For example, many parts of a car or truck have a complex volumetric shape. But at the same time they must be accurate. Moreover, they should have minimal errors and high quality surface treatment.

Various mechanical methods are used to process these parts and assemblies, including milling. Moreover, some parts cannot go with CNC machines without a milling operation.

Why Cnc Machining Car Parts for your car?

Generally, the heart of any car is its engine. In addition, the performance, resource and reliability of the car depend on how accurately. And it also depends on with high quality the heart of the car.

For example, without milling, it is impossible to make such important parts of a machine engine as the head and cylinder block. It is easy and simple to make these parts by milling on a computer numerical control (CNC) machine.

Processing of materials by cutting, with some varieties of which you are familiar with (turning, drilling, milling, planning, etc.), is uneconomical. Because it carries by significant waste of materials in the form of chips. In addition, many modern materials with high hardness are difficult to cut. There are also limitations on machining accuracy.

The widespread use of Обработка автомобильных запчастей с ЧПУ has become possible due to the mass, serial and single-piece production. Subsequently, there are many reasons for this.

Заключение

The main feature of C Cnc Machining Car Parts equipment is that information about a given law of motion of its controlled elements.

The use of CNC machines makes it possible to qualitatively change technological processes in mechanical engineering. Moreover, it improves the culture of production, reduce production areas, and eliminate the influence of subjective factors on product quality. In addition, it reduces production time, use a production strategy “just in time” and, as a result, achieve a large economic effect.

Если вы ищете профессиональную компанию по обработке с ЧПУ в Китае, мы можем вам помочь. Мы производим идеальные материалы для автомобильных деталей.