Quanto Cnc Machining Car Parts Cost Custo? (máquina cnc para indústria automotiva)

Quanto Cnc Machining Car Parts Cost custam? (Máquina CNC para Indústria Automotiva)

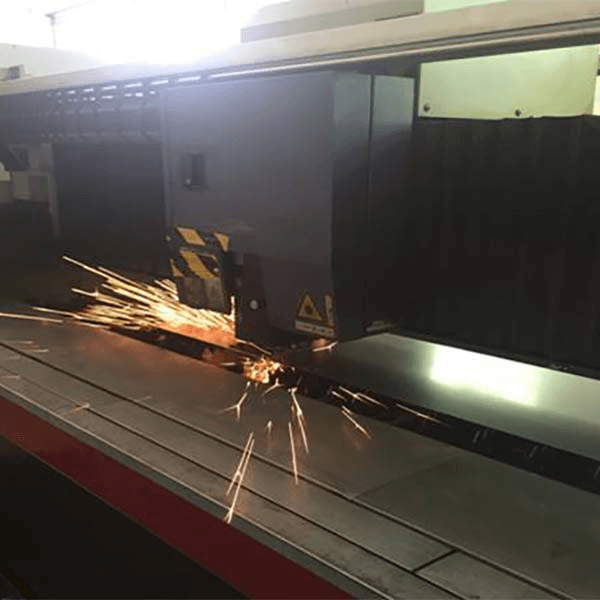

Fabricação de peças automotivas de usinagem Cnc de metal

Ao fabricar peças de carros de usinagem CNC usando fresamento, as máquinas CNC ajudam a obter peças de alta qualidade. E isso reduz significativamente seu custo. A fabricação de peças de reposição em metal em equipamentos inovadores permite obter peças geometricamente perfeitas. A fresagem em máquinas CNC pode até substituir a rectificação de produtos.

Working with metal using milling is becoming an indispensable element in many areas of human activity. Thus, metalworking using CNC machines allows us to fulfill orders for the advertising industry, in particular, the production of outdoor advertising. So, the production of spare parts, clichés or stamps, engraving on various surfaces come with a high level of image accuracy at high speed.

No caso da fabricação de peças de reposição em metal, o tamanho do lote não importa. Portanto, a automação pode lidar com qualquer número de peças com facilidade.

O que é importante para Cnc Machining Car Parts?

O que é importante - fresar ou tornear peças de carros de em máquinas CNC permite que você reduza a porcentagem de peças defeituosas ao mínimo. O ponto positivo é que o equipamento é capaz de funcionar dia e noite sem fadiga e doenças.

O processo de fabricação de peças automotivas de usinagem Cnc

- Estudo dos parâmetros e características da peça fabricada.

- Seleção da ferramenta e da peça de trabalho adequadas.

- Elaboração de um programa de acordo com o desenho do cliente. Além disso, levando em consideração as características de processamento para um tipo específico de metal e as especificações da peça.

- Programming and writing the converted data to the medium of the machine.

- Manufacturing of products in an automated mode. Similarly, we transmit special commands are to electronic controllers. The control system, using sensors monitors the execution of each command from the beginning to the end of the manufacturing process.

To write control programs, first create a 3D model in a CAD editor following cad programs are popular:

- AutoCAD

- CorelDRAW

- Rhinoceros 3D

- SolidWorks, etc.

Then import it into a CAM editor, where the control programs itself. The machine without human intervention accurately performs the following tasks:

- adjusts the number of revolutions;

- adjusts the amount of feed;

- Controls all parameters to obtain the specified shape and size of the part.

Thanks to this, the Cnc Machining Car Parts manufacturing process go by:

- low labor intensity

- alta produtividade

- maximum accuracy and compliance of finished parts with requirements without defects

- optimal repeatability in mass production of products

- low cost of parts for large-scale production

- excluding human error

CNC EQUIPMENT FOR MAKING CUSTOM PARTS

For the production of parts on CNC, imported equipment with numerical control is very common. Kaitom have all the necessary capacities and capabilities necessary for the implementation of small orders and large-scale production. Moreover, our manufacturing platform can supply high quality metal parts at the best price. And the whole process can be possible in the shortest possible time.

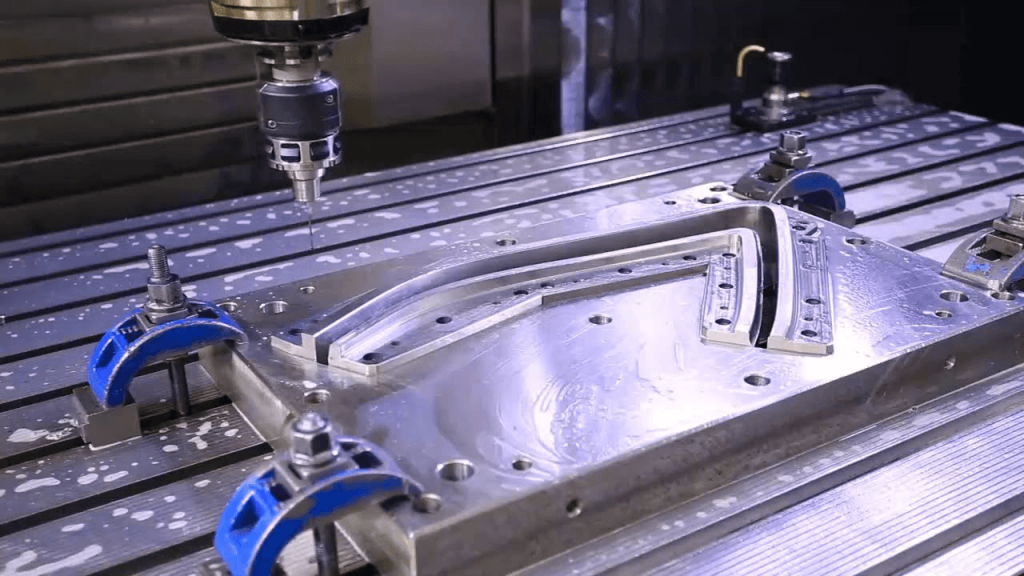

HORIZONTAL CONSOLE-TYPE MILLING MACHINE WITH CNC XK6040

Used to process:

- complex surfaces;

- matrices;

- molds;

- Parts for the engineering industry.

Similarly, it can perform the following types of work:

- milling

- drilling

- boring

Due to the accelerated movement of the working table in all directions, the processing of products occurs with high productivity. Suitable for milling workpieces made of steel, cast iron and non-ferrous metals.

Why cnc machining is so popular?

Recently, numerically controlled lathes have become widespread. Often, when the work profile changes or new products appear in the production process, it is necessary to change the programs for lathes. If your company does not have a specialist who can cope with such a task, we are pleased to offer you the services of our partners for the development of programs for CNC lathes.

Manufacturing peças de carros de is very common everywhere. In addition, you can order this service from our company. New equipment periodically comes to production and labor methods are constantly improving. Even such a delicate matter as turning is increasingly moving towards automation.

At the moment, at enterprises whose functions include the manufacture of spare parts, machine tools with program control are widely famous. Innovative technologies can significantly save time and guarantee material processing accuracy and high quality.

A huge advantage of CNC machines is their reprogramming capability. Subsequently, it does not take much time and allows for custom-made spare parts.

Spare parts with a multi-stage or curved surface are more expedient to produce on CNC lathes. Such technologies make it possible to produce a large number of high quality spare parts in a short time.

Recently, there has been a tendency to introduce an end-to-end production process, which will fully automate all stages of parts manufacturing. With the use of CNC machine tools, metalworking is accelerated at least twice.

Manufacturing of spare parts according to drawings

As mentioned above, CNC machines can produce peças de carros de even on an individual order, regardless of the amount of work. In order to order the manufacture of spare parts according to drawings, you must provide the company with a drawing of the required part.

Furthermore, a drawing in any production is the main document for accepting an order. The drawing should contain all the details of the order – the material, its physical characteristics and various specific nuances.

If it is necessary to produce an exclusive spare part, the part comes under testing to meet all the requirements stated in the order. In case of inaccuracies, the drawings are corrected and the production should be perfect.

The choice of production method depends on the:

- type

- tamanho e

- configuration of the part

The manufacture of spare parts requires compliance with all stages of production. So, the next step is to draw up a plan according to which the part requires development.

Deve-se ter em mente que é mais lucrativo fabricar grandes quantidades de peças de carros de . Ao produzir peças de reposição em máquinas CNC, você pode contar com a identidade de todas as peças de qualquer lote entre si.

Qual é o custo da Cnc Machining Car Parts?

O custo total e o tempo de fabricação de peças sob encomenda usando máquinas CNC vêm depois de levar em consideração os seguintes custos:

- material (marca, espessura, etc.) necessário para o trabalho;

- Complexidade e dimensões do produto, das quais dependem a criação de programas de controle e o ajuste de máquinas CNC;

- O número total de unidades do produto no pedido;

- A necessidade de acabamentos adicionais de acordo com a especificação (lixamento, revestimento, polimento, etc.).

Fresagem na indústria automotiva

The modern automotive industry uses the latest technologies and materials for peças de carros de. Hence, it includes metals and alloys, ceramics, composites and plastics.

With increasing competition, the requirements for nodes and car parts are going high. An increasing proportion of car parts are developing using technologies that were previously available only to the aircraft and space industries.

For example, many parts of a car or truck have a complex volumetric shape. But at the same time they must be accurate. Moreover, they should have minimal errors and high quality surface treatment.

Various mechanical methods are used to process these parts and assemblies, including milling. Moreover, some parts cannot go with CNC machines without a milling operation.

Why Cnc Machining Car Parts for your car?

Generally, the heart of any car is its engine. In addition, the performance, resource and reliability of the car depend on how accurately. And it also depends on with high quality the heart of the car.

For example, without milling, it is impossible to make such important parts of a machine engine as the head and cylinder block. It is easy and simple to make these parts by milling on a computer numerical control (CNC) machine.

Processing of materials by cutting, with some varieties of which you are familiar with (turning, drilling, milling, planning, etc.), is uneconomical. Because it carries by significant waste of materials in the form of chips. In addition, many modern materials with high hardness are difficult to cut. There are also limitations on machining accuracy.

The widespread use of peças de carros de has become possible due to the mass, serial and single-piece production. Subsequently, there are many reasons for this.

Conclusão

The main feature of C Cnc Machining Car Parts equipment is that information about a given law of motion of its controlled elements.

The use of CNC machines makes it possible to qualitatively change technological processes in mechanical engineering. Moreover, it improves the culture of production, reduce production areas, and eliminate the influence of subjective factors on product quality. In addition, it reduces production time, use a production strategy “just in time” and, as a result, achieve a large economic effect.

Se você estiver procurando por empresa de usinagem cnc profissional na China, podemos ajudá-lo. Fabricamos materiais perfeitos para peças automotivas.