O que é molde hdpe e moldagem por injeção hdpe: (guia de moldagem hdpe 2020)

O que é molde hdpe e moldagem por injeção hdpe : (guia de moldagem hdpe 2020)

Moldagem por injeção: futuro das indústrias

Hoje você pode ver os produtos que criaram usando materiais HDPE. Basicamente, todos os nossos artigos domésticos foram criados com a ajuda de materiais HDPE. Molde HDPE e moldagem por injeção HDPE se tornaram o processo de fabricação mais popular do mundo.

You can even see its most versatile production in your daily life accessories. Furthermore, HDPE has excellent properties that you can generally use it after recycling. Manufacturers are rapidly using with extreme versatility to produce your household objects. Such as, pipes, food containers, milk and water, auto parts and many, many more.

Moreover, the products which have created by HDPE are all around us but we never notice them. They are all the results of molding or injection molding. In fact, John Wesley was the person who introduced the molding technology in 1868.

He made billiard balls by requesting one of his dearest friends. Later 1n 1872 John and his brother Isaiah Hyatt patented their first injection molding machine. So, molding technology had actually introduced since 1800’s. But it has made growth from its beginnings to since now.

At first it only produced very small and simple objects. But today all products relating to,

- Industrial

- Médico

- Consumer

- Residential and

- Aerospace are manufacturing with the help of molding.

Hence, injection molding now has become our essential need. And we cannot even imagine producing any plastic or metal product without it.

So, in this guide, you will read about molding, injection molding and HDPE mold and HDPE injection molding in brief.

What is molding?

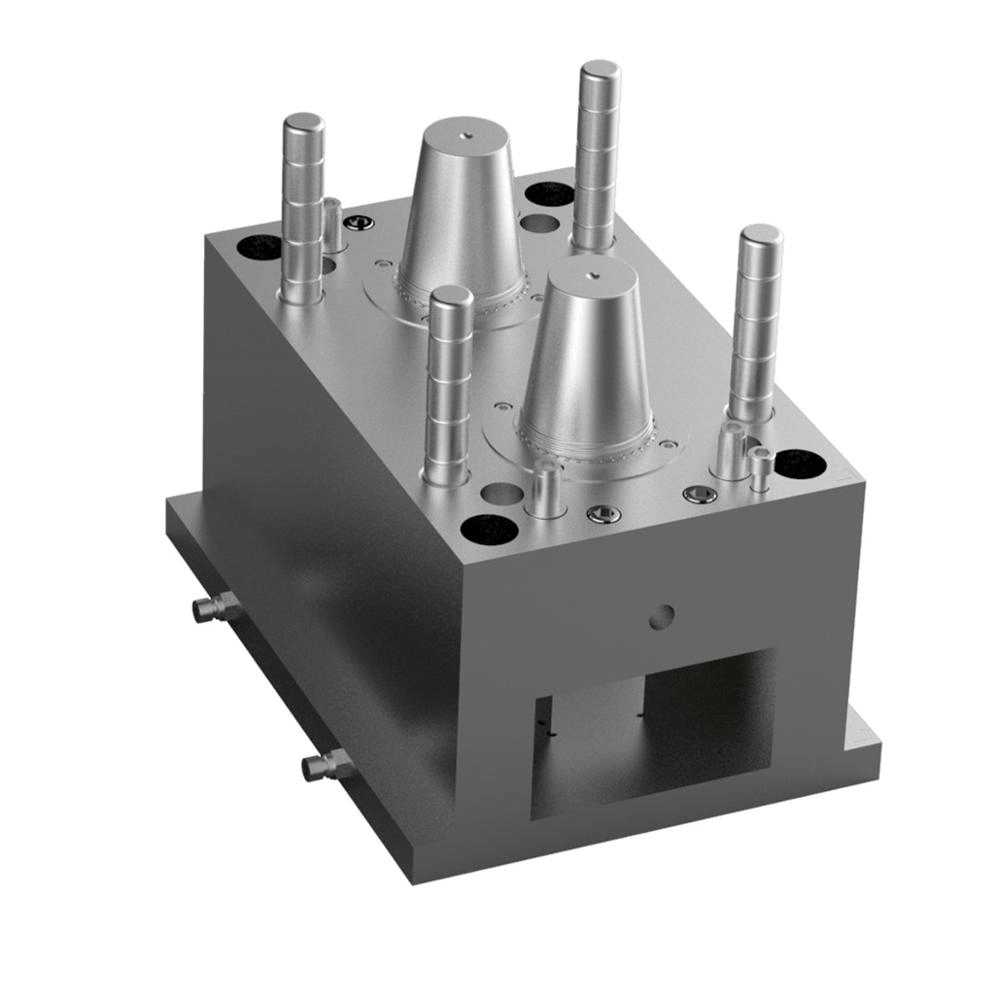

The process of shaping pliable or liquid materials into a specific shape with the help of a special rigid frame has known as molding. Furthermore, a mold actually is a hollowed-out block.

And you can easily create mold objects in this hollowed-out block. However, you can also use several raw materials to manufacture different products. These materials are:

- plastic

- metal

- glass

- Ceramic, etc.

What is the process of molding different objects?

In the process of molding, manufacturers put the liquid into the mold machine. This liquid has ability to set inside the mold machine and hence it adopts the required shape of your product. So, it is really simple process, just take an object which you want to make.

First you will create its impression with the help of another material which has known as a mold. Furthermore, you need a soft material for creating the shape of a mold. Additionally, in the next step pour or spread this soft material around the model. It usually takes time to become hard and this time has technically known as the “set time”.

Moreover, the process of making the mold cab is different because it totally depends on the material and shape of the model. For complex or very tiny model you will have to use two-part silicone mold. It has capability to cast complicated and smaller miniscule art easily.

Additionally, all the complex and miniscule molds consist several pieces which make a complete mold by joining together. Although they are expensive but really essential for creating the shapes

What are the different types of molding?

Molding has several different types. Moreover, it totally depends on the requirements and demands of your clients to select among these different kinds of molding. All the kinds are important and have special importance according to your needs. These kinds are:

- Powder metallurgy molding

- Compression and blow

- Extrusions molding

- Moldagem por injeção

- Matrix molding

- Transfer molding

- Thermoforming molding

What is injection molding?

In injection molding, you can manufacture many different parts with the help of injecting molten material into a mold. As you know that it is actually an important kind of molding. Today it is one of the most common used manufacturing methods for several advantageous reasons.

In the injection molding machines, you can simply heat the material and convert it into a liquid form. Later it will transfer into the shape of a mold or shape which you require. It is very valuable for consumer product development sectors because it is a best HDPE mold and HDPE moldagem por injeção.

Furthermore, the HDPE products are all around us. We are rapidly making use of these products as our household items. As it has the great resemblance to the method of injecting the hot liquid by making use of a syringe. So, this is the reason why it has assigned the name of injection molding.

What are the applications of injection molding?

Manufacturers are making use of injection molding for several years. But now they have got that generally injection molding is extremely cost-effective.

However, you can actually use it for high-volume manufacturing operations. In addition, it is also applicable for complex and small parts. These complex parts actually need,

- high performance

- força elevada

- Cost efficiency.

Você pode criar facilmente grandes peças de máquinas automotivas com a ajuda de grandes máquinas de moldagem. E máquinas menores são melhores para criar peças especiais e precisas para uso em aplicações cirúrgicas.

Assim, os fabricantes usam principalmente moldagem por injeção para criar várias peças para,

- aparelhos eletronicos

- telecomunicações

- indústrias de autopeças e assim por diante.

Quantos tipos de máquinas de moldagem por injeção existem?

Na verdade, a moldagem por injeção é realmente eficaz e econômica para a criação de vários milhares de peças por ano. Além disso, o processo de usinagem geralmente leva de 12 a 16 semanas ou mais para fins de grande produção. Mas depende totalmente do tipo de máquina que você está usando para a produção dos produtos.

Qual material é usado na moldagem por injeção?

Além disso, na moldagem por injeção você pode usar muitos materiais diferentes. Esses materiais são:

- óculos

- metais

- confeitos

- elastomers, etc.

But the most important and common materials are:

- thermosetting polymers

Mostly injection molding has used the material of plastic. Because plastic is synthetic or artificial material. And manufacturers use different injection molding machines to make several simple or complex objects.

Top ten extremely popular injection molding materials of today are:

- High-Density Polyethylene (HDPE)

- Nylon (Polyamide)

- Polycarbonate

- Polyoxymethylene (POM)

- Polypropylene (PP)

- Acrylic

- Thermoplastic Polyurethane (TPU)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyethylene (PE)

- Polystyrene (PS)

What is hdpe?

HDPE stands for High-density polyethylene resins. Basically, manufacturers are widely using HDPE for its great benefits. This material is generally best for the following molding techniques:

- moldagem por injeção

- moldagem por sopro

- rotational molding.

However, you can also get its great advantages in extrusion film applications for example:

- garbage

- deep-freezer bags

- grocery, etc.

In fact, the best suited technique for HDPE material is Molde HDPE e moldagem por injeção HDPE.

HDPE has also known as PEHD. Furthermore, PEHD stands for polyethylene high-density. Actually, polyethylene thermoplastic has created from petroleum. It provides you the wide versatility in manufacturing several products. In addition, it has extremely high strength-to-density composition.

Moreover, all these special features have made HDPE most popular plastic. HDPE is a kind of special plastic that you all have in their homes as many household items.

O que é Molde HDPE e moldagem por injeção HDPE ?

Basically, the molding process in HDPE injection molding is injection molding. And its main process is as under

First of all, you have to melt the material which you are going to mold. Then pour it into the mold. In the mold it becomes harden. In this way the products have taken out and we get the final design. With the help of HDPE injection molding we can shape even complicated and small shapes more quickly.

Additionally, with the help of this process we can manufacture our mass production very easily and more rapidly. Therefore, nowadays almost all industries depend on HPDE mold and HDPE injection molding to manufacture all their products.

Advantages of HDPE in Molde HDPE e moldagem por injeção HDPE

HDPE has splendid qualities as well as it is cost efficient. It totally suits your budget whether it is low or high. Furthermore, HDPE has extremely economical material selection for your next products demand or for mass production purposes.

In addition, its 6 most beneficial advantages are:

- Light-weight

- Hygienic

- FDA-approved

- Weather-resistance

- Recyclable

- Malleability

What are the various uses of HDPE?

Today, manufacturers are using HDPE in almost all our daily using products. You can see its uses from industrial to residential items.

HDPE gives its best benefits when we mold it using molding. You can convert it according to your needs in many different,

- styles

- sizes

It has particular optimal strength and linear structure. So, it is best in several extreme environmental stresses.

The special properties of HDPE in Molde HDPE e moldagem por injeção HDPE

Generally, HPDE and HDPE injection molding has countless positive features because it is a,

- strong

- durable

- low density plastic.

And it has special capability to resist in high temperatures. Moreover, its exceptional HDPE properties are:

- Tough

- versatile

- perfect chemical resistance

- Leve

- extremely low gravity

- medical and FDA also available.

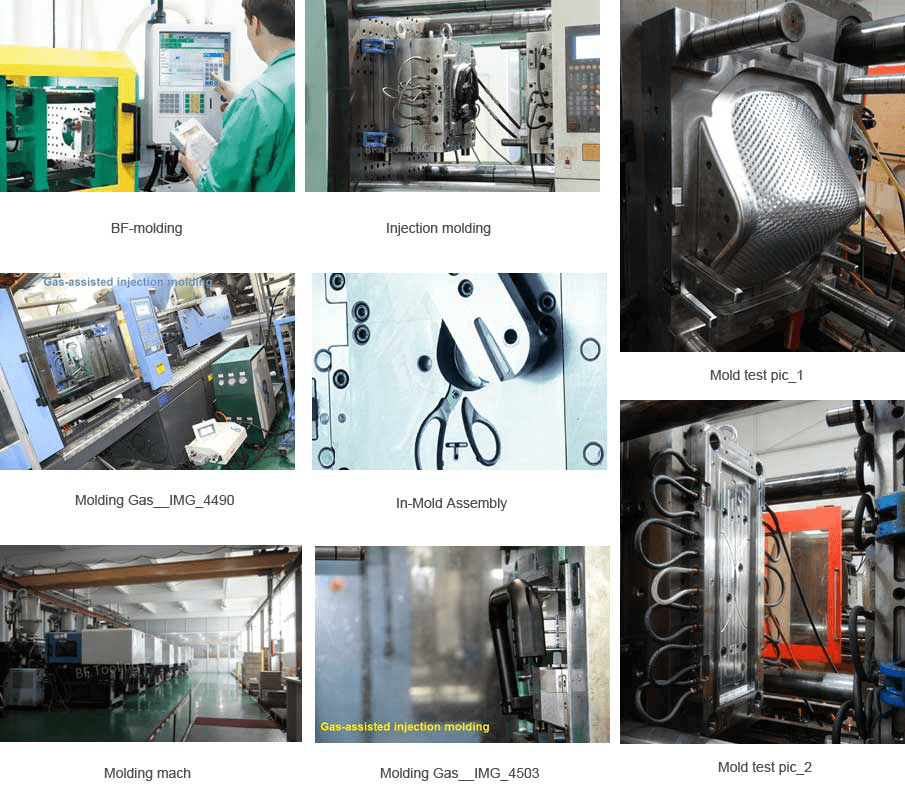

6 different kinds of Molde HDPE e moldagem por injeção HDPE technologies

Here are some most popular technologies of modern age. Furthermore, by using these molding techniques you can actually create your products with high precision and a rapid speed. In addition, these technologies are:

- Thin Wall Molding

- Liquid Silicone Injection Molding

- Metal Injection Molding

- Gas-assisted Injection Molding

- impressao 3D

- Unique Material Formulations.

Hence, you have a huge choice in selecting the HDPE molding technologies which suits your products demands.

What are the typical applications of Molde HDPE e moldagem por injeção HDPE ?

The typical uses of products which manufacturers create by using HDPE mold and HDPE injection molding are:

- storage vessels

- seal caps

- for containers in refrigeration units

- household goods

- kitchen items

- bases for PET bottles.

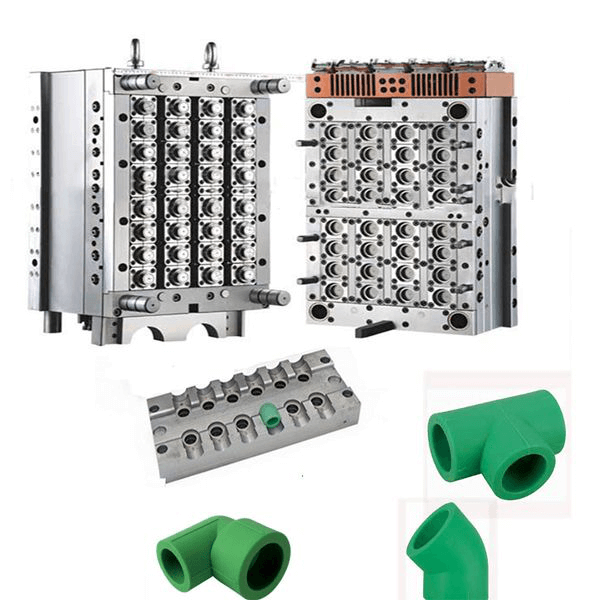

What are the industrial applications of Molde HDPE e moldagem por injeção HDPE ?

HDPE is more reliable for industrial products and manufacturers are rapidly using it in their items. Moreover, HDPE has more flexibility so it is an ideal choice for manufacturing products which are related to industrial products. so, these items are,

- Construction relating products

- Pipe thread protectors

- Hardware

- Medical application.

What are the consumer applications of HDPE mold and HDPE injection molding?

High Density Polyethylene plastic is extremely flexible and reliable and can be molded in any shape. So, it is also the first choice of the manufacturers of consumer products.

Hence, its consumer products are:

- Storage containers

- Appliances

- Brinquedos

- Milk crates

- Sporting goods.

Furthermore, it also has FDA grades and hence ideal for food storage products and infants’ toys. Medical industry is also relying on HDPE products because of its FDA grades and highly precision qualities.

Por que Molde HDPE e moldagem por injeção HDPE is ideal for everyday uses?

HDPE (High Density Polyethylene) items that have created by HDPE mold and HDPE injection molding technology are perfect for your every single day. People have realized its exceptional properties. Moreover, HDPE is also a special resin for assembly and packaging.

Essas características vantajosas o tornaram um dos plásticos mais usados. Indústrias de manufatura de todo o mundo agora dependem e contam com produtos HDPE. Possui grande versatilidade e você pode criar itens esplêndidos, mesmo para a sua produção em massa.

Conseqüentemente, os produtos de plástico HDPE são melhores não apenas para usos industriais, mas também dependem disso para nossos requisitos e necessidades diários. Além disso, seus usos diários são os seguintes:

- Materiais para piscina

- Tubos de plástico

- Capacetes

- Garrafas plásticas

- Cadeiras e mesas dobráveis

- Artigos de cozinha

- Acessórios de decoração e muito mais.

Conclusão:

Conseqüentemente, os produtos de plástico HDPE feitos com a ajuda de Molde HDPE e moldagem por injeção HDPE são altamente benéficos para todos os tipos de nossas necessidades. Hoje, confiamos totalmente e dependemos do material HDPE. Porque eles são,

- altamente eficiente

- mais durável

- econômico e extremamente resistente.

Basicamente, o HDPE foi introduzido no Reino Unido em 1930. No início, ele foi usado para cabos de radar durante a Segunda Guerra Mundial. Mais tarde, nos Estados Unidos, foi apresentado comercialmente e assim começa a ação. Além disso, sua popularidade começa desde então. E sua era de desenvolvimento começou a subir cada vez mais alto que na verdade nunca terá fim.