Khuôn hdpe và khuôn ép hdpe là gì: (Hướng dẫn đúc hdpe 2020)

Nhà Khuôn hdpe và khuôn ép hdpe: (Hướng dẫn đúc hdpe 2020)

Injection Molding: Future of Industries

Ngày nay bạn có thể thấy các sản phẩm được tạo ra bằng cách sử dụng vật liệu HDPE. Về cơ bản, tất cả các bài viết của ngôi nhà của chúng tôi đều được tạo ra với sự trợ giúp của vật liệu HDPE. Khuôn HDPE và khuôn ép HDPE đã trở thành quy trình sản xuất phổ biến nhất thế giới.

You can even see its most versatile production in your daily life accessories. Furthermore, HDPE has excellent properties that you can generally use it after recycling. Manufacturers are rapidly using with extreme versatility to produce your household objects. Such as, pipes, food containers, milk and water, auto parts and many, many more.

Moreover, the products which have created by HDPE are all around us but we never notice them. They are all the results of molding or injection molding. In fact, John Wesley was the person who introduced the molding technology in 1868.

He made billiard balls by requesting one of his dearest friends. Later 1n 1872 John and his brother Isaiah Hyatt patented their first injection molding machine. So, molding technology had actually introduced since 1800’s. But it has made growth from its beginnings to since now.

At first it only produced very small and simple objects. But today all products relating to,

- Industrial

- Y tế

- Consumer

- Residential and

- Aerospace are manufacturing with the help of molding.

Hence, injection molding now has become our essential need. And we cannot even imagine producing any plastic or metal product without it.

So, in this guide, you will read about molding, injection molding and HDPE mold and HDPE injection molding in brief.

What is molding?

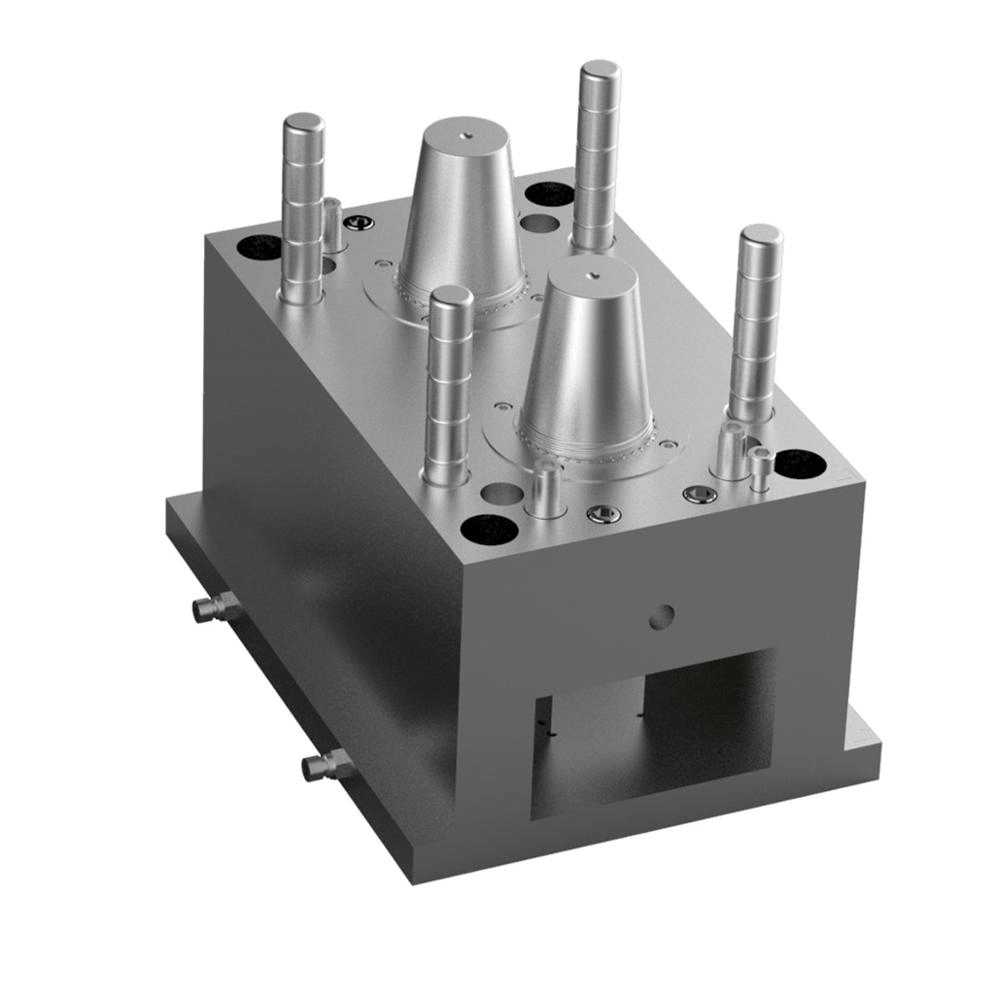

The process of shaping pliable or liquid materials into a specific shape with the help of a special rigid frame has known as molding. Furthermore, a mold actually is a hollowed-out block.

And you can easily create mold objects in this hollowed-out block. However, you can also use several raw materials to manufacture different products. These materials are:

- plastic

- metal

- glass

- Ceramic, etc.

What is the process of molding different objects?

In the process of molding, manufacturers put the liquid into the mold machine. This liquid has ability to set inside the mold machine and hence it adopts the required shape of your product. So, it is really simple process, just take an object which you want to make.

First you will create its impression with the help of another material which has known as a mold. Furthermore, you need a soft material for creating the shape of a mold. Additionally, in the next step pour or spread this soft material around the model. It usually takes time to become hard and this time has technically known as the “set time”.

Moreover, the process of making the mold cab is different because it totally depends on the material and shape of the model. For complex or very tiny model you will have to use two-part silicone mold. It has capability to cast complicated and smaller miniscule art easily.

Additionally, all the complex and miniscule molds consist several pieces which make a complete mold by joining together. Although they are expensive but really essential for creating the shapes

What are the different types of molding?

Molding has several different types. Moreover, it totally depends on the requirements and demands of your clients to select among these different kinds of molding. All the kinds are important and have special importance according to your needs. These kinds are:

- Powder metallurgy molding

- Compression and blow

- Extrusions molding

- Ép phun

- Matrix molding

- Transfer molding

- Thermoforming molding

What is injection molding?

In injection molding, you can manufacture many different parts with the help of injecting molten material into a mold. As you know that it is actually an important kind of molding. Today it is one of the most common used manufacturing methods for several advantageous reasons.

In the injection molding machines, you can simply heat the material and convert it into a liquid form. Later it will transfer into the shape of a mold or shape which you require. It is very valuable for consumer product development sectors because it is a best HDPE mold and HDPE ép phun.

Furthermore, the HDPE products are all around us. We are rapidly making use of these products as our household items. As it has the great resemblance to the method of injecting the hot liquid by making use of a syringe. So, this is the reason why it has assigned the name of injection molding.

What are the applications of injection molding?

Manufacturers are making use of injection molding for several years. But now they have got that generally injection molding is extremely cost-effective.

However, you can actually use it for high-volume manufacturing operations. In addition, it is also applicable for complex and small parts. These complex parts actually need,

- high performance

- high strength

- Cost efficiency.

You can easily create large parts of auto machines with the help of large molding machines. And smaller machines are best to create special and precise parts for the use of surgical applications.

So, manufacturers mostly use injection molding to create several parts for,

- electronic appliances

- telecommunications

- auto parts industries and so on.

How many types of injection molding machines are?

In fact, injection molding is really effective and economical for creating several thousand parts per year. Moreover, the tooling process generally takes 12-16 or more weeks for large production purposes. But it totally depends on the type of machine which you are using for the production of products.

Which material is used in injection molding?

Furthermore, in injection molding you can use many different materials. These materials are:

- glasses

- metals

- confections

- elastomers, etc.

But the most important and common materials are:

- thermosetting polymers

Mostly injection molding has used the material of plastic. Because plastic is synthetic or artificial material. And manufacturers use different injection molding machines to make several simple or complex objects.

Top ten extremely popular injection molding materials of today are:

- High-Density Polyethylene (HDPE)

- Nylon (Polyamide)

- Polycarbonate

- Polyoxymethylene (POM)

- Polypropylene (PP)

- Acrylic

- Thermoplastic Polyurethane (TPU)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyetylen (PE)

- Polystyrene (PS)

What is hdpe?

HDPE stands for High-density polyethylene resins. Basically, manufacturers are widely using HDPE for its great benefits. This material is generally best for the following molding techniques:

- ép phun

- thổi đúc

- rotational molding.

However, you can also get its great advantages in extrusion film applications for example:

- garbage

- deep-freezer bags

- grocery, etc.

In fact, the best suited technique for HDPE material is Khuôn HDPE và khuôn ép HDPE.

HDPE has also known as PEHD. Furthermore, PEHD stands for polyethylene high-density. Actually, polyethylene thermoplastic has created from petroleum. It provides you the wide versatility in manufacturing several products. In addition, it has extremely high strength-to-density composition.

Moreover, all these special features have made HDPE most popular plastic. HDPE is a kind of special plastic that you all have in their homes as many household items.

Nhà Khuôn HDPE và khuôn ép HDPEgì?

Basically, the molding process in HDPE injection molding is injection molding. And its main process is as under

First of all, you have to melt the material which you are going to mold. Then pour it into the mold. In the mold it becomes harden. In this way the products have taken out and we get the final design. With the help of HDPE injection molding we can shape even complicated and small shapes more quickly.

Additionally, with the help of this process we can manufacture our mass production very easily and more rapidly. Therefore, nowadays almost all industries depend on HPDE mold and HDPE injection molding to manufacture all their products.

Advantages of HDPE in Khuôn HDPE và khuôn ép HDPE

HDPE has splendid qualities as well as it is cost efficient. It totally suits your budget whether it is low or high. Furthermore, HDPE has extremely economical material selection for your next products demand or for mass production purposes.

In addition, its 6 most beneficial advantages are:

- Light-weight

- Hygienic

- FDA-approved

- Weather-resistance

- Recyclable

- Malleability

What are the various uses of HDPE?

Today, manufacturers are using HDPE in almost all our daily using products. You can see its uses from industrial to residential items.

HDPE gives its best benefits when we mold it using molding. You can convert it according to your needs in many different,

- styles

- sizes

It has particular optimal strength and linear structure. So, it is best in several extreme environmental stresses.

Các tính chất đặc biệt của HDPE trong Khuôn HDPE và khuôn ép HDPE

Nói chung, ép phun HPDE và HDPE có vô số tính năng tích cực bởi vì nó là

- mạnh

- bền chặt

- nhựa mật độ thấp.

Và nó có khả năng đặc biệt để chống lại nhiệt độ cao. Hơn nữa, các đặc tính đặc biệt của HDPE là:

- Khó khăn

- linh hoạt

- kháng hóa chất hoàn hảo

- Nhẹ

- trọng lực cực thấp

- y tế và FDA cũng có sẵn.

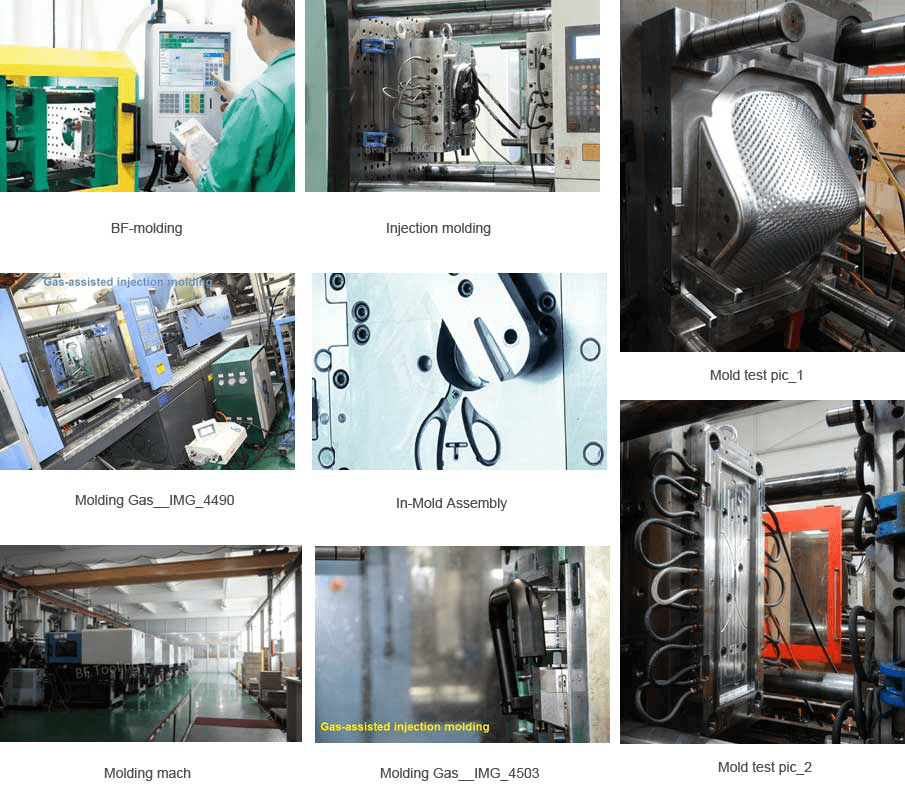

6 loại Khuôn HDPE và khuôn ép HDPE technologies

Dưới đây là một số công nghệ phổ biến nhất của thời đại hiện đại. Hơn nữa, bằng cách sử dụng các kỹ thuật đúc này, bạn thực sự có thể tạo ra các sản phẩm của mình với độ chính xác cao và tốc độ nhanh chóng. Ngoài ra, các công nghệ này là:

- Khuôn đúc tường mỏng

- Khuôn ép silicon lỏng

- Khuôn ép kim loại

- Gas-assisted Injection Molding

- in 3d

- Unique Material Formulations.

Hence, you have a huge choice in selecting the HDPE molding technologies which suits your products demands.

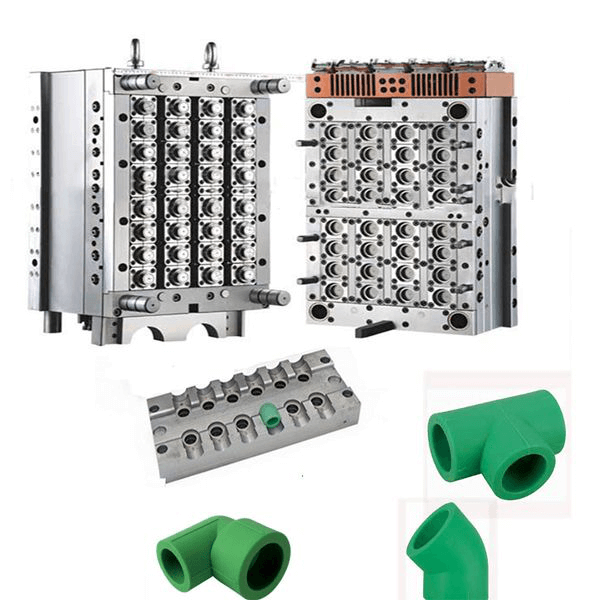

What are the typical applications of Khuôn HDPE và khuôn ép HDPEgì?

The typical uses of products which manufacturers create by using HDPE mold and HDPE injection molding are:

- storage vessels

- seal caps

- for containers in refrigeration units

- household goods

- kitchen items

- bases for PET bottles.

What are the industrial applications of Khuôn HDPE và khuôn ép HDPEgì?

HDPE is more reliable for industrial products and manufacturers are rapidly using it in their items. Moreover, HDPE has more flexibility so it is an ideal choice for manufacturing products which are related to industrial products. so, these items are,

- Construction relating products

- Pipe thread protectors

- Hardware

- Medical application.

What are the consumer applications of HDPE mold and HDPE injection molding?

High Density Polyethylene plastic is extremely flexible and reliable and can be molded in any shape. So, it is also the first choice of the manufacturers of consumer products.

Hence, its consumer products are:

- Storage containers

- Appliances

- Đồ chơi

- Milk crates

- Sporting goods.

Furthermore, it also has FDA grades and hence ideal for food storage products and infants’ toys. Medical industry is also relying on HDPE products because of its FDA grades and highly precision qualities.

Tại sao Khuôn HDPE và khuôn ép HDPE is ideal for everyday uses?

HDPE (High Density Polyethylene) items that have created by HDPE mold and HDPE injection molding technology are perfect for your every single day. People have realized its exceptional properties. Moreover, HDPE is also a special resin for assembly and packaging.

Những tính năng ưu việt này đã khiến nó trở thành một loại nhựa được sử dụng rộng rãi nhất. Các ngành sản xuất từ khắp nơi trên thế giới hiện đang phụ thuộc và dựa vào các sản phẩm HDPE. Nó có tính linh hoạt cao và bạn có thể tạo ra những món đồ lộng lẫy ngay cả khi sản xuất hàng loạt.

Do đó, các sản phẩm nhựa HDPE tốt nhất không chỉ sử dụng trong công nghiệp mà các yêu cầu và nhu cầu hàng ngày của chúng ta cũng tùy thuộc vào nó. Ngoài ra, cách sử dụng hàng ngày của nó như sau:

- Vật liệu bể bơi

- Ống nhựa

- Mũ cứng

- Chai nhựa

- Bàn ghế gấp

- Đồ nhà bếp

- Trang trí phụ kiện và nhiều hơn nữa.

Phần kết luận:

Do đó, các sản phẩm Nhựa HDPE được sản xuất với sự trợ giúp của Khuôn HDPE và khuôn ép HDPE rất có lợi cho mọi nhu cầu của chúng ta. Ngày nay, chúng tôi hoàn toàn tin tưởng và phụ thuộc vào vật liệu HDPE. Tại vi họ la,

- hiệu quả cao

- bền hơn

- tiết kiệm chi phí và cực kỳ chống chịu.

Về cơ bản, HDPE được giới thiệu ở Anh vào những năm 1930. Lúc đầu, nó được sử dụng cho cáp radar trong Thế chiến II. Sau đó, ở Mỹ, nó đã được giới thiệu thương mại và vì vậy hành động bắt đầu. Hơn nữa, sự phổ biến của nó bắt đầu kể từ đó. Và kỷ nguyên phát triển của nó bắt đầu tăng cao và thực sự sẽ không bao giờ kết thúc.