Cos'è lo stampo hdpe e lo stampaggio a iniezione hdpe: (guida allo stampaggio hdpe 2020)

Che cos'è il stampo hdpe e lo stampaggio a iniezione hdpe : (guida allo stampaggio hdpe 2020)

Stampaggio a iniezione: il futuro delle industrie

Oggi puoi vedere i prodotti che hanno creato utilizzando materiali HDPE. Fondamentalmente, tutti i nostri articoli per la casa sono stati creati con l'aiuto di materiali HDPE. Stampo in HDPE e stampaggio a iniezione in HDPE sono diventati il processo di produzione più popolare al mondo.

You can even see its most versatile production in your daily life accessories. Furthermore, HDPE has excellent properties that you can generally use it after recycling. Manufacturers are rapidly using with extreme versatility to produce your household objects. Such as, pipes, food containers, milk and water, auto parts and many, many more.

Moreover, the products which have created by HDPE are all around us but we never notice them. They are all the results of molding or injection molding. In fact, John Wesley was the person who introduced the molding technology in 1868.

He made billiard balls by requesting one of his dearest friends. Later 1n 1872 John and his brother Isaiah Hyatt patented their first injection molding machine. So, molding technology had actually introduced since 1800’s. But it has made growth from its beginnings to since now.

At first it only produced very small and simple objects. But today all products relating to,

- Industrial

- Medico

- Consumer

- Residential and

- Aerospace are manufacturing with the help of molding.

Hence, injection molding now has become our essential need. And we cannot even imagine producing any plastic or metal product without it.

So, in this guide, you will read about molding, injection molding and HDPE mold and HDPE injection molding in brief.

What is molding?

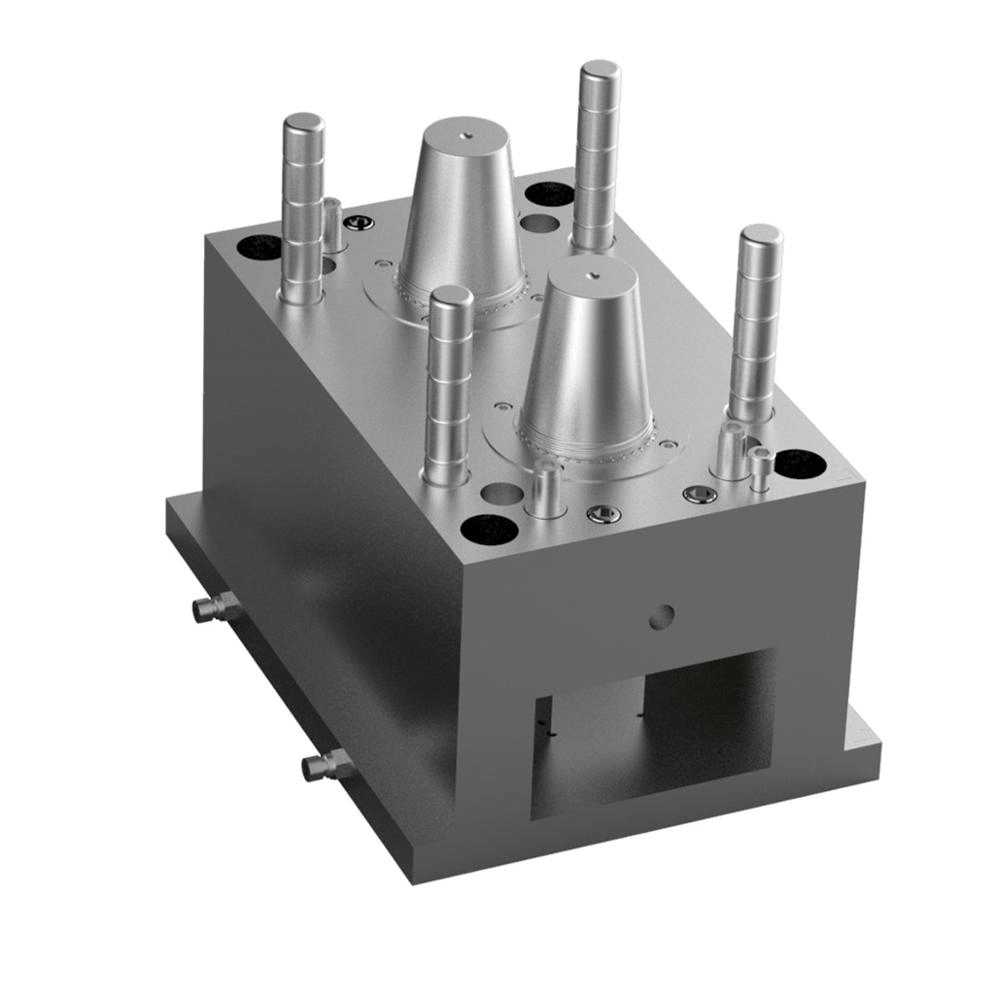

The process of shaping pliable or liquid materials into a specific shape with the help of a special rigid frame has known as molding. Furthermore, a mold actually is a hollowed-out block.

And you can easily create mold objects in this hollowed-out block. However, you can also use several raw materials to manufacture different products. These materials are:

- plastic

- metal

- bicchiere

- Ceramica, ecc.

Qual è il processo di stampaggio di oggetti diversi?

Nel processo di stampaggio, i produttori mettono il liquido nella macchina stampo. Questo liquido ha la capacità di fissarsi all'interno della macchina stampo e quindi adotta la forma richiesta del prodotto. Quindi, è un processo davvero semplice, basta prendere un oggetto che si desidera creare.

Per prima cosa creerai la sua impressione con l'aiuto di un altro materiale che ha conosciuto come uno stampo. Inoltre, è necessario un materiale morbido per creare la forma di uno stampo. Inoltre, nel passaggio successivo versare o distribuire questo materiale morbido attorno al modello. Di solito ci vuole tempo per diventare difficile e questo tempo è tecnicamente noto come "tempo impostato".

Moreover, the process of making the mold cab is different because it totally depends on the material and shape of the model. For complex or very tiny model you will have to use two-part silicone mold. It has capability to cast complicated and smaller miniscule art easily.

Additionally, all the complex and miniscule molds consist several pieces which make a complete mold by joining together. Although they are expensive but really essential for creating the shapes

What are the different types of molding?

Molding has several different types. Moreover, it totally depends on the requirements and demands of your clients to select among these different kinds of molding. All the kinds are important and have special importance according to your needs. These kinds are:

- Powder metallurgy molding

- Compression and blow

- Extrusions molding

- Stampaggio a iniezione

- Matrix molding

- Transfer molding

- Thermoforming molding

What is injection molding?

In injection molding, you can manufacture many different parts with the help of injecting molten material into a mold. As you know that it is actually an important kind of molding. Today it is one of the most common used manufacturing methods for several advantageous reasons.

In the injection molding machines, you can simply heat the material and convert it into a liquid form. Later it will transfer into the shape of a mold or shape which you require. It is very valuable for consumer product development sectors because it is a best HDPE mold and HDPE stampaggio a iniezione.

Furthermore, the HDPE products are all around us. We are rapidly making use of these products as our household items. As it has the great resemblance to the method of injecting the hot liquid by making use of a syringe. So, this is the reason why it has assigned the name of injection molding.

What are the applications of injection molding?

Manufacturers are making use of injection molding for several years. But now they have got that generally injection molding is extremely cost-effective.

However, you can actually use it for high-volume manufacturing operations. In addition, it is also applicable for complex and small parts. These complex parts actually need,

- high performance

- high strength

- Cost efficiency.

You can easily create large parts of auto machines with the help of large molding machines. And smaller machines are best to create special and precise parts for the use of surgical applications.

So, manufacturers mostly use injection molding to create several parts for,

- electronic appliances

- telecommunications

- auto parts industries and so on.

How many types of injection molding machines are?

In fact, injection molding is really effective and economical for creating several thousand parts per year. Moreover, the tooling process generally takes 12-16 or more weeks for large production purposes. But it totally depends on the type of machine which you are using for the production of products.

Which material is used in injection molding?

Furthermore, in injection molding you can use many different materials. These materials are:

- glasses

- metals

- confections

- elastomers, etc.

But the most important and common materials are:

- thermosetting polymers

Mostly injection molding has used the material of plastic. Because plastic is synthetic or artificial material. And manufacturers use different injection molding machines to make several simple or complex objects.

Top ten extremely popular injection molding materials of today are:

- High-Density Polyethylene (HDPE)

- Nylon (Polyamide)

- Polycarbonate

- Polyoxymethylene (POM)

- Polypropylene (PP)

- Acrylic

- Thermoplastic Polyurethane (TPU)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyethylene (PE)

- Polystyrene (PS)

What is hdpe?

HDPE stands for High-density polyethylene resins. Basically, manufacturers are widely using HDPE for its great benefits. This material is generally best for the following molding techniques:

- stampaggio a iniezione

- blow molding

- rotational molding.

However, you can also get its great advantages in extrusion film applications for example:

- garbage

- deep-freezer bags

- grocery, etc.

In fact, the best suited technique for HDPE material is Stampo in HDPE e stampaggio a iniezione in HDPE.

HDPE has also known as PEHD. Furthermore, PEHD stands for polyethylene high-density. Actually, polyethylene thermoplastic has created from petroleum. It provides you the wide versatility in manufacturing several products. In addition, it has extremely high strength-to-density composition.

Moreover, all these special features have made HDPE most popular plastic. HDPE is a kind of special plastic that you all have in their homes as many household items.

Che cos'è il Stampo in HDPE e stampaggio a iniezione in HDPE?

Basically, the molding process in HDPE injection molding is injection molding. And its main process is as under

First of all, you have to melt the material which you are going to mold. Then pour it into the mold. In the mold it becomes harden. In this way the products have taken out and we get the final design. With the help of HDPE injection molding we can shape even complicated and small shapes more quickly.

Additionally, with the help of this process we can manufacture our mass production very easily and more rapidly. Therefore, nowadays almost all industries depend on HPDE mold and HDPE injection molding to manufacture all their products.

Advantages of HDPE in Stampo in HDPE e stampaggio a iniezione in HDPE

L'HDPE ha ottime qualità ed è conveniente. Si adatta perfettamente al tuo budget, sia basso che alto. Inoltre, l'HDPE ha una selezione di materiali estremamente economica per la tua prossima domanda di prodotti o per scopi di produzione di massa.

Inoltre, i suoi 6 vantaggi più vantaggiosi sono:

- Leggero

- Igienico

- Approvato dalla FDA

- Resistenza agli agenti atmosferici

- Riciclabile

- Malleabilità

Quali sono i vari usi dell'HDPE?

Oggi i produttori utilizzano l'HDPE in quasi tutti i nostri prodotti di uso quotidiano. Puoi vedere i suoi usi dagli elementi industriali a quelli residenziali.

L'HDPE offre i suoi migliori vantaggi quando lo stampiamo utilizzando lo stampaggio. Puoi convertirlo in base alle tue esigenze in molti diversi,

- stili

- dimensioni

Ha una particolare robustezza ottimale e struttura lineare. Quindi, è meglio in diversi stress ambientali estremi.

The special properties of HDPE in Stampo in HDPE e stampaggio a iniezione in HDPE

Generally, HPDE and HDPE injection molding has countless positive features because it is a,

- strong

- durable

- low density plastic.

And it has special capability to resist in high temperatures. Moreover, its exceptional HDPE properties are:

- Tough

- versatile

- perfect chemical resistance

- Lightweight

- extremely low gravity

- medical and FDA also available.

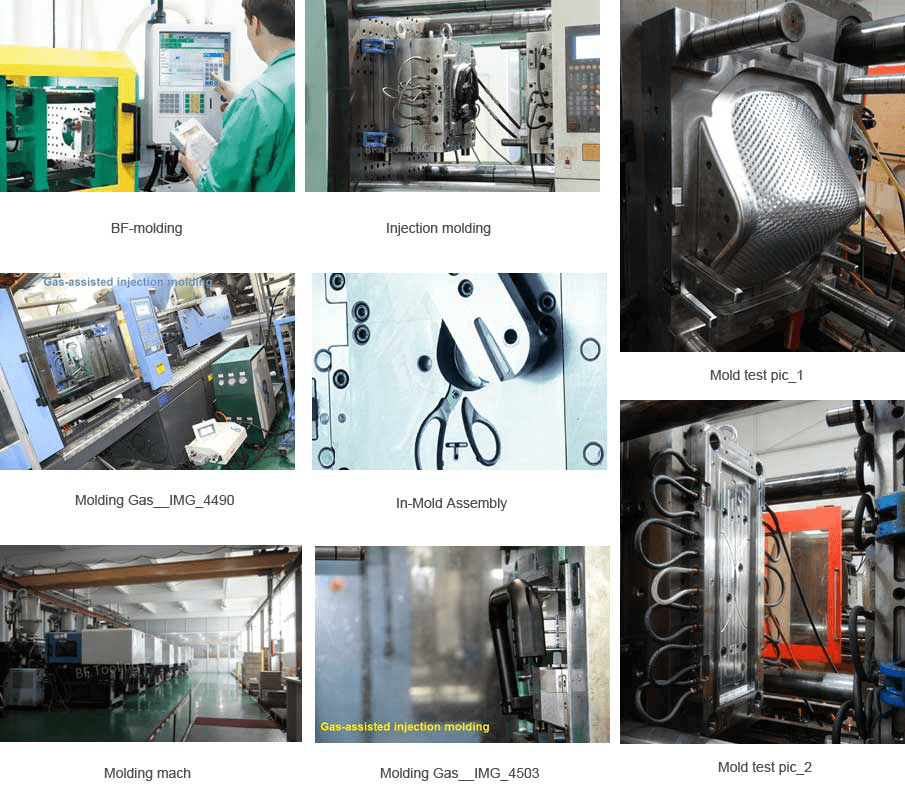

6 different kinds of Stampo in HDPE e stampaggio a iniezione in HDPE technologies

Here are some most popular technologies of modern age. Furthermore, by using these molding techniques you can actually create your products with high precision and a rapid speed. In addition, these technologies are:

- Thin Wall Molding

- Liquid Silicone Injection Molding

- Metal Injection Molding

- Gas-assisted Injection Molding

- 3D Printing

- Unique Material Formulations.

Hence, you have a huge choice in selecting the HDPE molding technologies which suits your products demands.

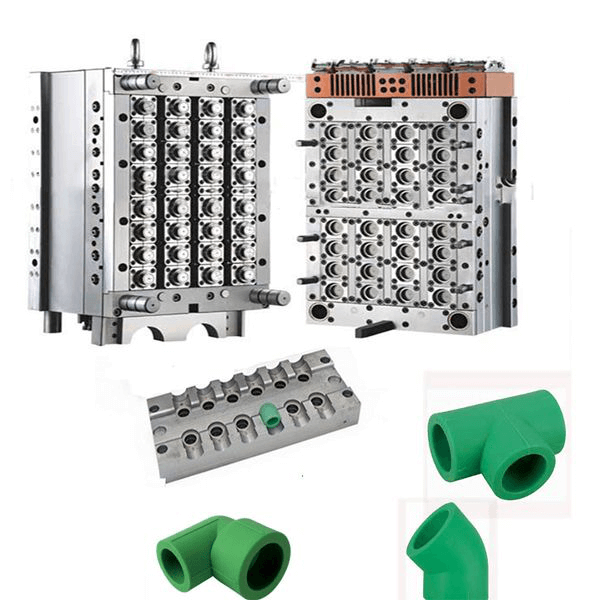

What are the typical applications of Stampo in HDPE e stampaggio a iniezione in HDPE?

The typical uses of products which manufacturers create by using HDPE mold and HDPE injection molding are:

- storage vessels

- seal caps

- for containers in refrigeration units

- household goods

- kitchen items

- bases for PET bottles.

What are the industrial applications of Stampo in HDPE e stampaggio a iniezione in HDPE?

HDPE is more reliable for industrial products and manufacturers are rapidly using it in their items. Moreover, HDPE has more flexibility so it is an ideal choice for manufacturing products which are related to industrial products. so, these items are,

- Construction relating products

- Pipe thread protectors

- Hardware

- Medical application.

What are the consumer applications of HDPE mold and HDPE injection molding?

High Density Polyethylene plastic is extremely flexible and reliable and can be molded in any shape. So, it is also the first choice of the manufacturers of consumer products.

Hence, its consumer products are:

- Storage containers

- Appliances

- Toys

- Milk crates

- Sporting goods.

Furthermore, it also has FDA grades and hence ideal for food storage products and infants’ toys. Medical industry is also relying on HDPE products because of its FDA grades and highly precision qualities.

Perché Stampo in HDPE e stampaggio a iniezione in HDPE is ideal for everyday uses?

HDPE (High Density Polyethylene) items that have created by HDPE mold and HDPE injection molding technology are perfect for your every single day. People have realized its exceptional properties. Moreover, HDPE is also a special resin for assembly and packaging.

These advantageous features have made it one the most widely used plastic. Manufacturing industries from all over the world are now depending and relying on HDPE products. It has great versatility and you can create splendid items even for your mass production.

Hence, HDPE plastic products are best not only for industrial uses but our everyday requirements and needs are also depending on it. In addition, its everyday uses are as follows:

- Swimming pool materials

- Plastic pipes

- Hard hats

- Plastic bottles

- Folding chairs and tables

- Kitchen items

- Decorating accessories and many more.

Conclusion:

Hence HDPE Plastic products which has made with the help of Stampo in HDPE e stampaggio a iniezione in HDPE are highly beneficial for all kinds of our needs. Today, we are totally trusting and depending on HDPE material. Because they are,

- highly efficient

- more durable

- cost effective and extremely resistant.

Basically, HDPE introduced in the UK in 1930s. At first it had used for radar cables during WWII. Later, in the US, it was commercially introduced and so the action begins. Furthermore, its popularity starts since then. And Its era of development began to rise high and high which will actually never end.