¿Qué es el molde de HDPE y el moldeo por inyección de HDPE? (Guía de moldeo de HDPE 2020)

¿Qué es el molde de HDPE y el moldeo por inyección de HDPE ? (Guía de moldeo de HDPE 2020)

Moldeo por inyección: el futuro de las industrias

Hoy puede ver los productos que se han creado utilizando materiales HDPE. Básicamente, todos nuestros artículos domésticos se han creado con la ayuda de materiales HDPE. Molde de HDPE y moldeo por inyección de HDPE han convertido en el proceso de fabricación más popular del mundo.

You can even see its most versatile production in your daily life accessories. Furthermore, HDPE has excellent properties that you can generally use it after recycling. Manufacturers are rapidly using with extreme versatility to produce your household objects. Such as, pipes, food containers, milk and water, auto parts and many, many more.

Moreover, the products which have created by HDPE are all around us but we never notice them. They are all the results of molding or injection molding. In fact, John Wesley was the person who introduced the molding technology in 1868.

He made billiard balls by requesting one of his dearest friends. Later 1n 1872 John and his brother Isaiah Hyatt patented their first injection molding machine. So, molding technology had actually introduced since 1800’s. But it has made growth from its beginnings to since now.

At first it only produced very small and simple objects. But today all products relating to,

- Industrial

- Médico

- Consumer

- Residential and

- Aerospace are manufacturing with the help of molding.

Hence, injection molding now has become our essential need. And we cannot even imagine producing any plastic or metal product without it.

So, in this guide, you will read about molding, injection molding and HDPE mold and HDPE injection molding in brief.

What is molding?

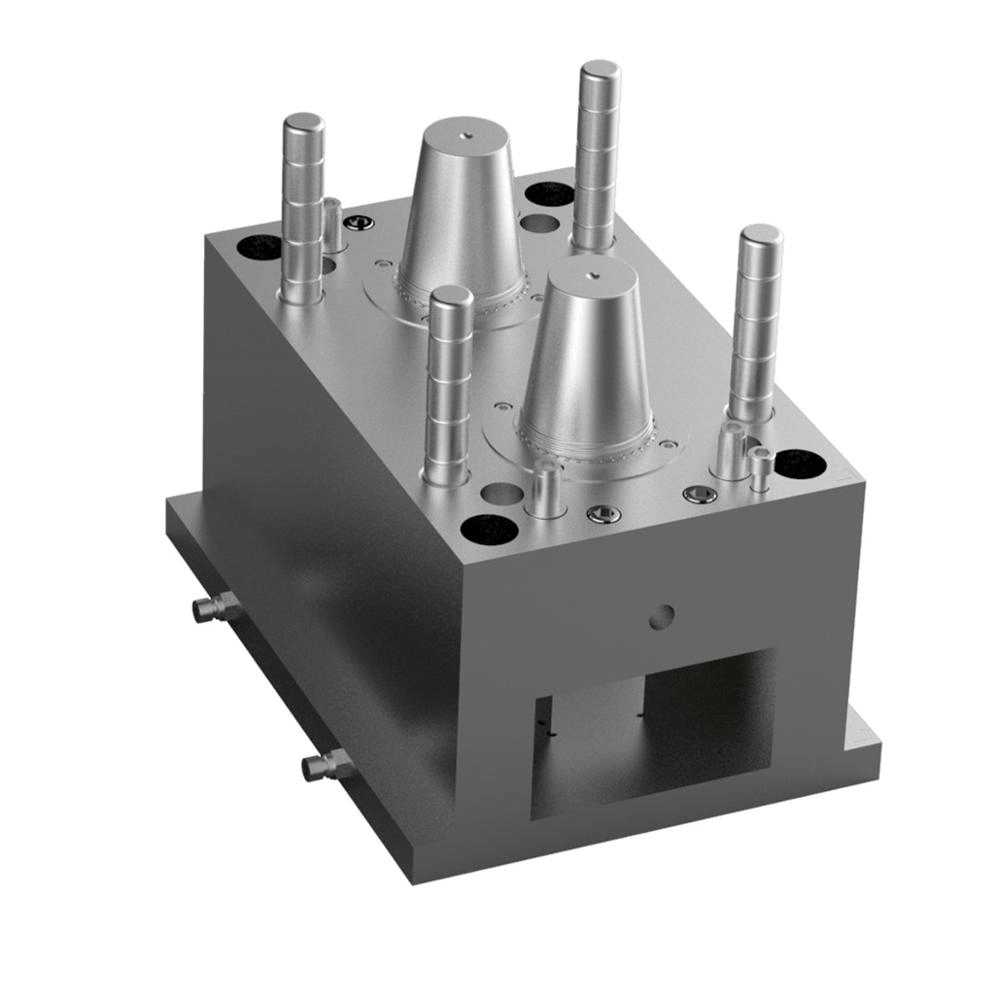

The process of shaping pliable or liquid materials into a specific shape with the help of a special rigid frame has known as molding. Furthermore, a mold actually is a hollowed-out block.

And you can easily create mold objects in this hollowed-out block. However, you can also use several raw materials to manufacture different products. These materials are:

- plastic

- metal

- glass

- Ceramic, etc.

What is the process of molding different objects?

In the process of molding, manufacturers put the liquid into the mold machine. This liquid has ability to set inside the mold machine and hence it adopts the required shape of your product. So, it is really simple process, just take an object which you want to make.

First you will create its impression with the help of another material which has known as a mold. Furthermore, you need a soft material for creating the shape of a mold. Additionally, in the next step pour or spread this soft material around the model. It usually takes time to become hard and this time has technically known as the “set time”.

Moreover, the process of making the mold cab is different because it totally depends on the material and shape of the model. For complex or very tiny model you will have to use two-part silicone mold. It has capability to cast complicated and smaller miniscule art easily.

Additionally, all the complex and miniscule molds consist several pieces which make a complete mold by joining together. Although they are expensive but really essential for creating the shapes

What are the different types of molding?

Molding has several different types. Moreover, it totally depends on the requirements and demands of your clients to select among these different kinds of molding. All the kinds are important and have special importance according to your needs. These kinds are:

- Powder metallurgy molding

- Compression and blow

- Extrusions molding

- Moldeo por inyección

- Matrix molding

- Transfer molding

- Thermoforming molding

What is injection molding?

In injection molding, you can manufacture many different parts with the help of injecting molten material into a mold. As you know that it is actually an important kind of molding. Today it is one of the most common used manufacturing methods for several advantageous reasons.

In the injection molding machines, you can simply heat the material and convert it into a liquid form. Later it will transfer into the shape of a mold or shape which you require. It is very valuable for consumer product development sectors because it is a best HDPE mold and HDPE moldeo por inyección .

Furthermore, the HDPE products are all around us. We are rapidly making use of these products as our household items. As it has the great resemblance to the method of injecting the hot liquid by making use of a syringe. So, this is the reason why it has assigned the name of injection molding.

What are the applications of injection molding?

Manufacturers are making use of injection molding for several years. But now they have got that generally injection molding is extremely cost-effective.

However, you can actually use it for high-volume manufacturing operations. In addition, it is also applicable for complex and small parts. These complex parts actually need,

- high performance

- high strength

- Cost efficiency.

Puede crear fácilmente piezas grandes de máquinas automotrices con la ayuda de grandes máquinas de moldeo. Y las máquinas más pequeñas son las mejores para crear piezas especiales y precisas para el uso de aplicaciones quirúrgicas.

Por lo tanto, los fabricantes utilizan principalmente el moldeo por inyección para crear varias piezas para,

- aparatos electrónicos

- telecomunicaciones

- industrias de autopartes y así sucesivamente.

¿Cuántos tipos de máquinas de moldeo por inyección hay?

De hecho, el moldeo por inyección es realmente efectivo y económico para crear varios miles de piezas por año. Además, el proceso de mecanizado suele tardar entre 12 y 16 semanas o más para grandes fines de producción. Pero depende totalmente del tipo de máquina que esté utilizando para la producción de productos.

¿Qué material se utiliza en el moldeo por inyección?

Además, en el moldeo por inyección se pueden utilizar muchos materiales diferentes. Estos materiales son:

- lentes

- rieles

- dulces

- elastomers, etc.

But the most important and common materials are:

- thermosetting polymers

Mostly injection molding has used the material of plastic. Because plastic is synthetic or artificial material. And manufacturers use different injection molding machines to make several simple or complex objects.

Top ten extremely popular injection molding materials of today are:

- High-Density Polyethylene (HDPE)

- Nylon (Polyamide)

- Polycarbonate

- Polioximetileno (POM)

- Polipropileno (PP)

- Acrílico

- Thermoplastic Polyurethane (TPU)

- Acrylonitrile Butadiene Styrene (ABS)

- Polietileno (PE)

- Poliestireno (PS)

What is hdpe?

HDPE stands for High-density polyethylene resins. Basically, manufacturers are widely using HDPE for its great benefits. This material is generally best for the following molding techniques:

- moldeo por inyección

- blow molding

- rotational molding.

However, you can also get its great advantages in extrusion film applications for example:

- garbage

- deep-freezer bags

- grocery, etc.

In fact, the best suited technique for HDPE material is Molde de HDPE y moldeo por inyección de HDPE.

HDPE has also known as PEHD. Furthermore, PEHD stands for polyethylene high-density. Actually, polyethylene thermoplastic has created from petroleum. It provides you the wide versatility in manufacturing several products. In addition, it has extremely high strength-to-density composition.

Moreover, all these special features have made HDPE most popular plastic. HDPE is a kind of special plastic that you all have in their homes as many household items.

¿Qué es el Molde de HDPE y moldeo por inyección de HDPE ?

Basically, the molding process in HDPE injection molding is injection molding. And its main process is as under

First of all, you have to melt the material which you are going to mold. Then pour it into the mold. In the mold it becomes harden. In this way the products have taken out and we get the final design. With the help of HDPE injection molding we can shape even complicated and small shapes more quickly.

Additionally, with the help of this process we can manufacture our mass production very easily and more rapidly. Therefore, nowadays almost all industries depend on HPDE mold and HDPE injection molding to manufacture all their products.

Advantages of HDPE in Molde de HDPE y moldeo por inyección de HDPE

El HDPE tiene cualidades espléndidas y es rentable. Se adapta totalmente a su presupuesto, ya sea bajo o alto. Además, HDPE tiene una selección de materiales extremadamente económica para su próxima demanda de productos o para fines de producción en masa.

Además, sus 6 ventajas más beneficiosas son:

- Ligero

- Higiénico

- Aprobado por la FDA

- Resistencia al clima

- Reciclable

- Maleabilidad

¿Cuáles son los diversos usos del HDPE?

Hoy en día, los fabricantes utilizan HDPE en casi todos nuestros productos de uso diario. Puede ver sus usos desde artículos industriales hasta residenciales.

El HDPE ofrece sus mejores beneficios cuando lo moldeamos mediante moldeo. Puede convertirlo según sus necesidades en muchos diferentes,

- estilos

- tamaños

Tiene una resistencia y una estructura lineal óptimas particulares. Por lo tanto, es mejor en varias situaciones de estrés ambiental extremo.

The special properties of HDPE in Molde de HDPE y moldeo por inyección de HDPE

Generally, HPDE and HDPE injection molding has countless positive features because it is a,

- strong

- durable

- low density plastic.

And it has special capability to resist in high temperatures. Moreover, its exceptional HDPE properties are:

- Tough

- versatile

- perfect chemical resistance

- Ligero

- extremely low gravity

- medical and FDA also available.

6 different kinds of Molde de HDPE y moldeo por inyección de HDPE technologies

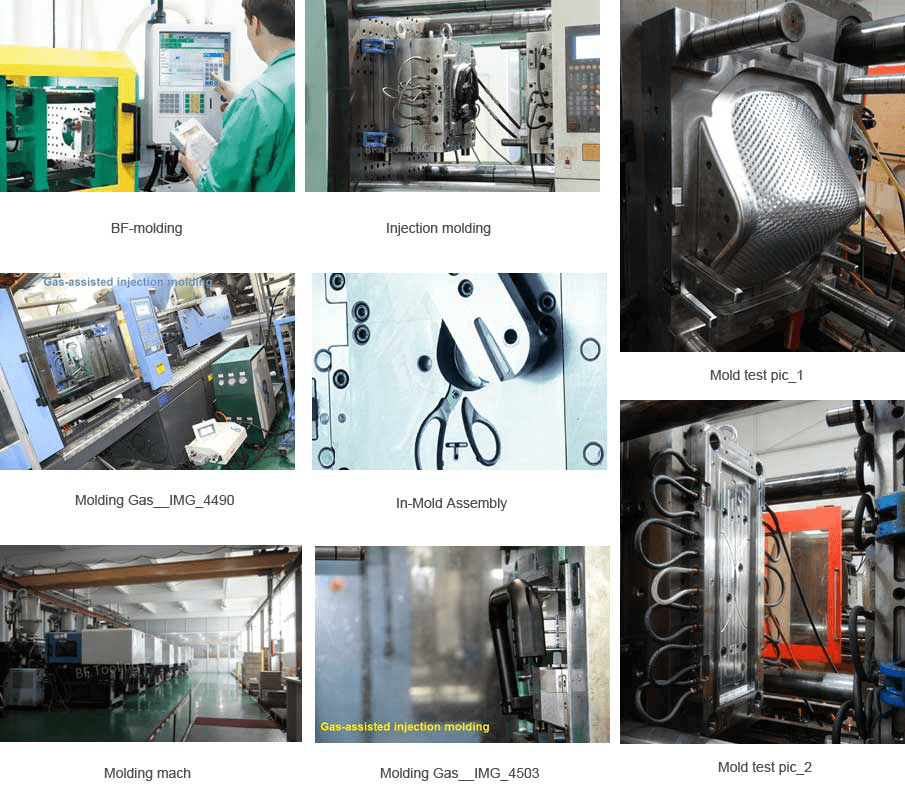

Here are some most popular technologies of modern age. Furthermore, by using these molding techniques you can actually create your products with high precision and a rapid speed. In addition, these technologies are:

- Thin Wall Molding

- Liquid Silicone Injection Molding

- Metal Injection Molding

- Gas-assisted Injection Molding

- Impresión 3d

- Unique Material Formulations.

Hence, you have a huge choice in selecting the HDPE molding technologies which suits your products demands.

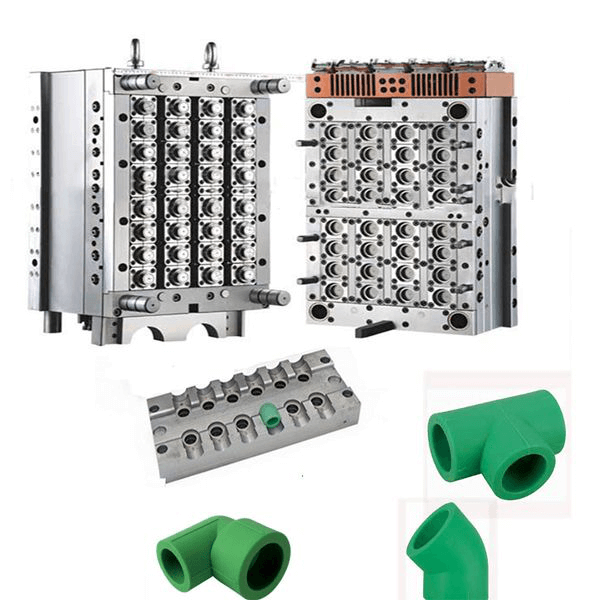

What are the typical applications of Molde de HDPE y moldeo por inyección de HDPE ?

The typical uses of products which manufacturers create by using HDPE mold and HDPE injection molding are:

- storage vessels

- seal caps

- for containers in refrigeration units

- household goods

- kitchen items

- bases for PET bottles.

What are the industrial applications of Molde de HDPE y moldeo por inyección de HDPE ?

El HDPE es más confiable para productos industriales y los fabricantes lo están utilizando rápidamente en sus artículos. Además, el HDPE tiene más flexibilidad, por lo que es una opción ideal para fabricar productos relacionados con productos industriales. entonces, estos elementos son,

- Productos relacionados con la construcción

- Protectores de rosca de tubería

- Hardware

- Aplicación médica.

¿Cuáles son las aplicaciones para el consumidor del HDPE y el moldeo por inyección de HDPE?

El plástico de polietileno de alta densidad es extremadamente flexible y confiable y se puede moldear en cualquier forma. Por lo tanto, también es la primera opción de los fabricantes de productos de consumo.

Por tanto, sus productos de consumo son:

- Contenedores de almacenamiento

- Accesorios

- Juguetes

- Cajas de leche

- Artículos deportivos.

Furthermore, it also has FDA grades and hence ideal for food storage products and infants’ toys. Medical industry is also relying on HDPE products because of its FDA grades and highly precision qualities.

Por qué Molde de HDPE y moldeo por inyección de HDPE is ideal for everyday uses?

HDPE (High Density Polyethylene) items that have created by HDPE mold and HDPE injection molding technology are perfect for your every single day. People have realized its exceptional properties. Moreover, HDPE is also a special resin for assembly and packaging.

These advantageous features have made it one the most widely used plastic. Manufacturing industries from all over the world are now depending and relying on HDPE products. It has great versatility and you can create splendid items even for your mass production.

Hence, HDPE plastic products are best not only for industrial uses but our everyday requirements and needs are also depending on it. In addition, its everyday uses are as follows:

- Swimming pool materials

- Plastic pipes

- Hard hats

- Plastic bottles

- Folding chairs and tables

- Kitchen items

- Decorating accessories and many more.

Conclusión:

Hence HDPE Plastic products which has made with the help of Molde de HDPE y moldeo por inyección de HDPE are highly beneficial for all kinds of our needs. Today, we are totally trusting and depending on HDPE material. Because they are,

- altamente eficiente

- más durable

- rentable y extremadamente resistente.

Básicamente, el HDPE se introdujo en el Reino Unido en la década de 1930. Al principio se había utilizado para cables de radar durante la Segunda Guerra Mundial. Más tarde, en Estados Unidos, se introdujo comercialmente y así comienza la acción. Además, su popularidad comienza desde entonces. Y su era de desarrollo comenzó a crecer cada vez más, lo que en realidad nunca terminará.