Importance du matériel, des machines et de la méthode pour le fabricant de moules en plastique

Fabricant de moules en plastique: Les 5 M - Partie II

Nous avons déjà mentionné comment les deux premières «Ms» - Moule et Homme - ont un impact sur la productivité d'un fabricant de moules en plastique. Cependant, pour exceller, le fabricant doit travailler sur tous les 5 M.

It is important to understand that the material poses great challenges. Their lot-to-lot differences are perhaps the biggest threat to repeatability. Therefore, the manufacturer should have the right skills and the desired expertise to tackle this issue efficiently.

The remaining two M’s Method and Machinery also hold great importance. Lack of attention to these aspects of the process will result in bigger challenges. Here, in this article, we are going to talk about the remaining three M’s and their importance.

Material: The Third M

The manufacturers need to pay close heed to the materials that are going to use. After all, the processing of the material plays a vital role in determining the quality of the end result.

Several variables have a positive or negative impact on the material. It is imperative to review them during the process development stages. In addition, the manufacturers can review them for continuous improvement.

Properties

Different materials possess a different set of properties. Smart manufacturers understand that they need to consider these properties in order to design and develop effective molding operations. Several properties are related to the parts dimensions and aesthetics sense.

Below, we have come up with important properties.

Shrinkage

When choosing the material, the manufacturer needs to consider its shrinkage factor. Since every material has its own shrinkage rate, therefore the manufacturer should have knowledge regarding its shrinkage rate.

Temperature

Temperature plays a critical role in the molding equation. The manufacturer needs to focus on the temperature of both the barrel and the mold. Lack of proper temperature can lead to a number of problems including gassing, burn at end of fill, warping and long cycles.

Aesthetics and Dimensions

Plastic die mould manufacturer understands that there are different variations. The variations on the engineered materials either detract of benefit the efficiency of the part production process.

In order to find the best materials solutions, a good idea is to reach out to the material manufacturer. Utilize their knowledge regarding materials in order to make a more informed decision.

Melt Flow

Another important factor that requires consideration is the material viscosity. The material viscosity is imperative for improvement and development review.

For example, if manufacturers want to assure the swift movement of the flowfront, then they need to pair a heavily ribbed part with a material with love viscosity. This would prevent the overpack condition and enhances usability.

Additives

Material additives have the ability to solve problems. However, at the same time, they can cause problems. Thus, the manufacture needs to use it with care. A good example of additives is the color mixing option.

Color mixing is inexpensive. Poor diffusion leads to scrap generation that results in fault parts because of color swirls. On the other hand, if you add lubricant to polypropylene, you might be able to prevent the parts from being stuck to molds that do not allow draft addition.

The best way to go about is to involve your material supplier. This will help you understand the material properties in a better way. Thus, you will be able to make the right decisions at the right time.

Drying

To ensure process consistency, as a manufacturer you need to focus on the drying aspect. Ensure that your dryers are capable to dry the material in adequate time. There should be no lack or wet areas left behind.

Use the moisture analysis to ensure 100% material drying. Thus would eliminate any further problems that a wet area might cause.

Characteristics

Before a manufacturer finalizes a material, he should focus on its characteristics. It is important to complete knowledge reading the material’s drawbacks and performance. For example, polypropylene is an excellent material. It does have problems, especially over deep or large ribs.

Likewise, nylon is another great choice, but its shrinking tendency is often a turn-off. The idea here is to select a material that matches the functionalities of the parts under production. Materials’ characteristics consideration would avoid numerous potential problems associated with materials. The right material would go a long way.

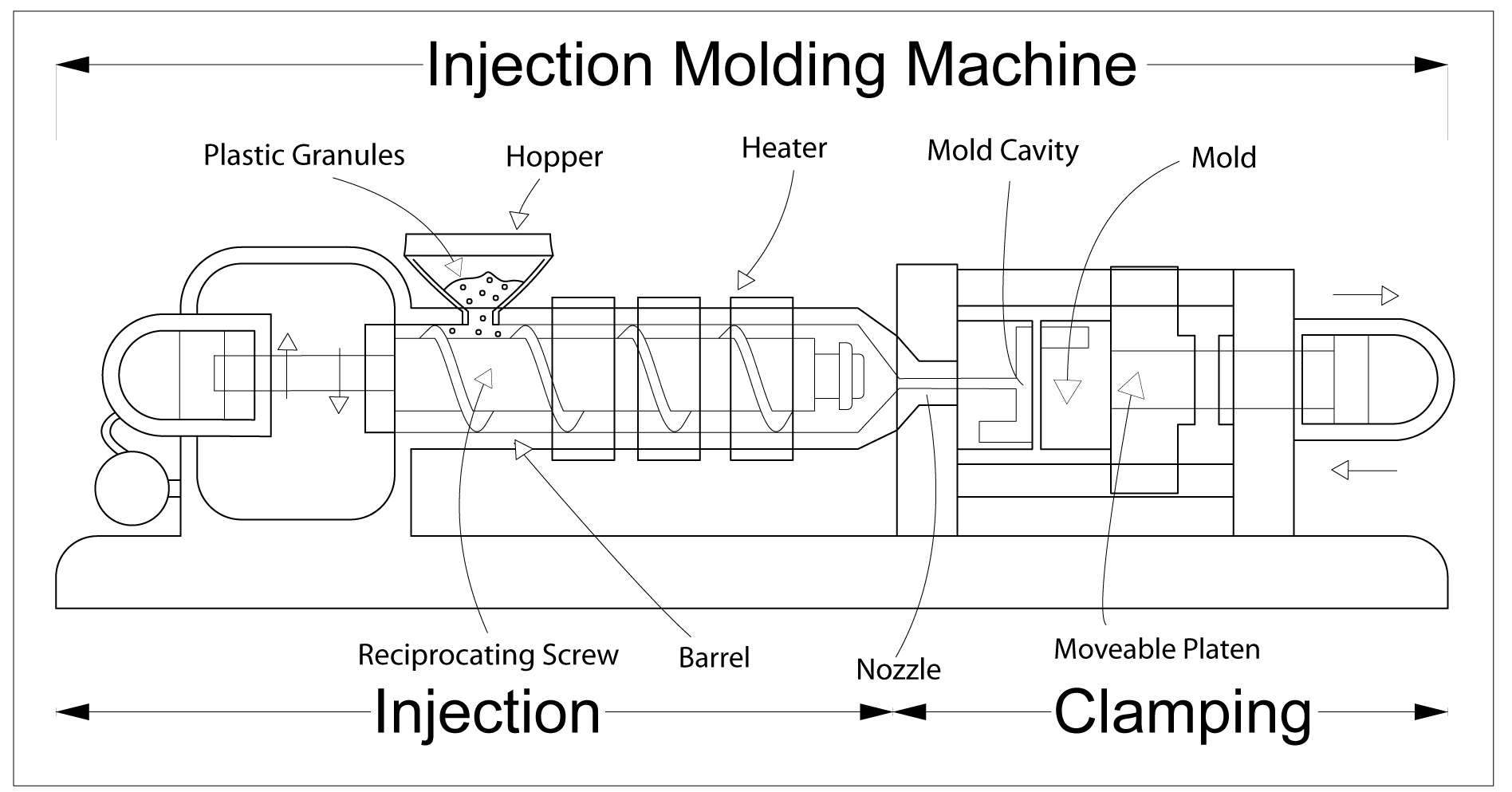

Machinery: The Forth M’s

Les machines et équipements ont un impact direct sur votre norme de moulage. Par conséquent, pour garantir des moules de haute qualité, vous devez disposer du dernier équipement. De plus, vous devez évaluer pleinement les capacités de vos machines.

Lorsque vous aurez une connaissance complète du potentiel de votre équipement, vous serez en mesure d'éviter un système de production qui fonctionne mal. Les composants suivants affectent directement l'installation, la productivité et les temps d'arrêt d'une ferraille.

Robot

Pour mettre en place des systèmes qualité et assurer une production de haut niveau, les industriels utilisent la robotique. Ces robots sont extrêmement importants pour améliorer l'efficience et l'efficacité des processus. Par conséquent, il est toujours judicieux d'examiner les correctifs potentiels pour l'amélioration du robot.

Par exemple, concentrez-vous sur les mises à jour, les changements de programmation, les bogues de code, les outils de fin de bras, entre autres. Un examen en temps opportun de ces aspects améliorera non seulement la fonctionnalité du processus, mais permettra également d'économiser les coûts de reprise.

Ress

On ne peut nier l'importance des capacités de la machine en termes de conception du système de fabrication. Dans la cohérence du processus, la conception des vis et le tonnage de la presse revêtent une grande importance. Les fabricants doivent s'assurer que les machines fonctionnant mal ne limitent pas le processus de production.

Par conséquent, faire correspondre le moule et le matériau devrait être leur priorité absolue. En outre, les fabricants devraient évaluer plus avant les problèmes de la machine et le contrôle du processus en utilisant les données de processus.

Automatisation

It is important to review all sources of automation. If the quality concerns are continuously repeating itself, plastic die mould manufacturers can make improvements via automation development. To identify current failures and to prevent failure failures, involve everyone on the production team.

Allow engineers to come up with effective and efficient solutions. In addition, make sure that your personnel and operators are well equipped to face any challenge. They should be able to identify and overcome problems in the production equation.

To assure the efficiency of equipment, you should carry out a preventative maintenance routine. You might face serious problems due to unscheduled downtime. It will have an adverse effect on production efficiencies.

The best way to prevent poor performance, you need to conduct scheduled maintenance events. With the right kind of preventative maintenance schedule in the below areas, you can improve the overall efficiency.

NOTE: Make sure that every area has its own personal log that keeps a record of the problems and their repeat time.

Molding Machine

When you have a regular inspection system in place, you can effortlessly avoid press breakdowns. Below, we did list some important inspections along with their repeat time.

Heater Bands

Repetition Time: Monthly

Ensure that all bands are in perfect working condition.

Electrical

Repetition Time: Weekly

Verify the integrity of the connectors. In addition, search for unsafe conditions.

Screw

Repetition Time: Bi-Annually

You need to verify the condition by metering the barrel zone. In addition, measure shank and flights to determine the wear’s condition. Lastly, you should remove the screw to fully, inspect them.

Hoses

Repetition Time: Weekly

You need to inspect hoses for blistering, rubbing and wearing signs.

Hydraulic Fluid

Repetition Time: Quarterly

Take the fluid sample and send it to a screener. This will help you evaluate viscosity break down and meta content.

Tooling

To prevent hours of downtime, you should conduct a 10-minute inspection of every mold per shift. It is important to keep a record of these molds. Use this data to create robust and strong molds in the future.

Method: The Fifth M

Make sure that the machine is completely ready for the process set up sheet. A slightly variation in the set up sheet can lead to bigger issues in no time. To avoid this problem, combine a set up sheet with a process adjustment log.

Doing this will help identify a potential problem and it will also help prevent future issues. In addition, ensure that process deviation is off bound. Until, unless the process manager explicitly approves of it. Once you do any sort of process variation, you should instantly update the book.

À emporter

Concentrating on the 5 M’s of the injection industry, the plastic die mould manufacturer can assure excellence. They will be able to maximize their productivity without compromising on their quality.

Des entreprises comme Katio Mold, se concentrent principalement sur les 5 M pour offrir des produits de la plus haute qualité et répondre aux normes les plus élevées de l'industrie. Ils ont l'expérience et l'expertise pour livrer des produits incroyables.

Les 5 millions de fabricants de moulage par injection - Partie I

Si nous pouvons vous aider avec votre projet, veuillez nous appeler au 0086-769-82821468 ou par e-mail un .