How does aluminum die casting manufacturer & rapid prototyping get quality prototypes?

Aluminium Die Casting Manufacturer and Rapid Prototyping

The low melting point of aluminum die casting manufacturer & rapid prototyping allows the use of a permanent mold. Similarly, we use this steel to make foundry parts. In die casting, an injection piston pushes the liquid aluminum into the mold cavity.

Later, it compresses the part during solidification. Typically, liquid metal reaches attack speeds of up to 60 meters per second. Similarly, the applied pressure can reach up to 800 bar during solidification.

The molding press keeps the mold closed by a closing force. It is for to contain the pressure exerted on the part, it depends on the size of the cavity and the pressure applied by the piston.

What is the capacity of aluminum die casting machines?

The smallest presses have a capacity of 1000 kN and the larger ones 35000 kN. The force of the press is therefore directly related to the projected surface of the molded part.

Generally, the die-casting process is divided into 6 phases:

- liquid metal transfer

- injection approach phase

- rapid injection

- Intensification

- ejection and mold lubrication

Each phase is optimized to maximize the production rate. Moreover, it minimizes the number of rejected parts.

There are three variants of aluminum die casting manufacturer & rapid prototyping process:

- Traditional die-casting

- Vacuum die casting including vacuum casting for structural applications

- Semi solid die-casting, much less common.

The main advantage of the process is the rapid rate. It makes it possible for aluminum die casting manufacturer & rapid prototyping to lower production costs. Moreover, it helps to approach mass markets such as the automobile.

Why rapid prototyping?

The rapid cooling provided by the metal mold produces a very fine metallurgical structure on the surface called a skin. It contributes to obtaining good mechanical properties.

The surface finish and dimensional tolerances are excellent. On the other hand, the design freedom is practically limited to the opening axis of the mold.

What is the process of aluminum die casting & rapid prototyping?

The process requires little labor. But it consumes a cost of immobilization and tools. For a large run of over 10,000 parts, the aluminum die casting manufacturer & rapid prototyping offers the lowest production cost per part among foundry processes.

The main disadvantage of the traditional process is the presence of porosity in the center of the die-cast parts. It is due to the air trapped during injection. The presence of trapped air causes blistering when the room is heated.

These blisters are caused by the expansion of the gas trapped in the room. In addition, they do not allow standard heat treatments. It is for to obtain optimal mechanical properties. This phenomenon also limits the use of soldering.

Fortunately, the mechanical resistance is ensured by the skin of the molding. It means that aluminum die casting manufacturer & rapid prototyping molds several castings by this method.

What is the role of alloys in aluminum casting?

It represents more than 50% of the aluminum castings produced. In traditional pressure casting, secondary alloys are often used with a high proportion of alloying element. It gives good mechanical resistance despite an elongation of less than 3%.

T5 type heat treatment is used to increase the mechanical strength of die-cast alloys. It happens without causing blistering of the parts. Secondary alloys are often used with a high proportion of alloying element.

It gives good mechanical resistance despite an elongation of less than 3%.

How does Aluminum die casting manufacturer & rapid prototyping get quality prototypes?

Aluminum die casting manufacturer & rapid prototyping obtains very good part quality by using a vacuum in the cavity. It prevents air trapping. Moreover, it controls the molding cycle in real time.

The high vacuum pressure process allows to obtain a maximum elongation at break. Moreover, it makes the heat treatment possible for the parts. These developments are motivated by the weight reduction of land vehicles.

Generally, vacuum die casting provides the ideal solution of a high speed casting process. Therefore, it is best for structural parts cast in aluminum. The development of this process is currently the most active in the field of aluminum die casting manufacturer & rapid prototyping.

Elements of a mold and production cell

The die-casting process is divided into two principles.

- Hot chamber technology and

- Cold chamber technology.

The hot chamber process uses a piston. It places directly in the molten metal bath to feed the mold. Similarly, the cold chamber process uses a “cold” container. We transfer the liquid metal in it by ladle.

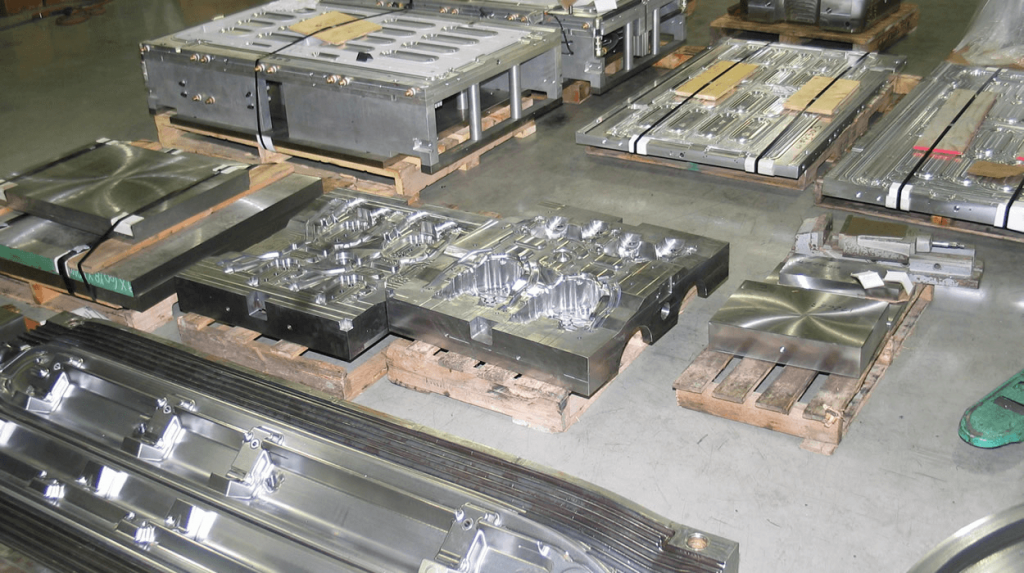

Description of die casting mold

In most cases, the pressure mold is made up of two ferrous alloy metal shells. Depending on the number of pieces provided, the materials used for the manufacture of the shells are:

- H13 type tool steel

- Type 4140 alloy steel

- P20 tool steel for the support parts

Aluminum die casting manufacturer & rapid prototyping makes the ejection rods with a harder material. Moreover, in some cases they get surface treatment. It limits sticking of the aluminum.

What is aluminum die casting mold?

The mold is composed of a fixed part on the side of the liquid metal supply. Similarly, it has a movable part on the other. The fixed part contains the metal entry hole and part of the coin cavity.

It can also have cores to mold cavities in the part. The mobile part contains the ejection rods used for remolding. It is for the cores and the part impression. The molds are equipped with oil or water cooling channels. It also serves to preheat the mold initially in the case of hot oil.

How does aluminum die casting manufacturer & rapid prototyping reduce prototyping cost?

To reduce tooling costs, the cavity often consists of a main insert placed in a larger, permanent frame that can produce more than one type of part. The inserts or molds typically belong to the customer.

The process is well suited for thin walls down to 1.5mm. It is preferable to use uniform sections which solidify simultaneously. There are no weights. Moreover, the attacks on the parts are small to facilitate cutting on debarring presses after casting.

The design of the parts makes extensive use of the ribs. It is to increase rigidity and mechanical strength. Subsequently, it also helps fill the cavity quickly before the alloy solidifies.

The turbulence of the metal in the cavity is controlled by the following factors:

- speed of metal injection

- the size and positioning

- the shape of the cavity and

- Use of wash heels

Aluminum die casting manufacturer & rapid prototyping use it to balance the movement of the metal. Moreover, they use it to capture the inclusions formed during filling. In the case of vacuum, the vacuum application parameters are also important for filling.

The injection unit is a complex hydraulic system. It consists of following parts:

- an injection accumulator

- an injection cylinder

- multiplier accumulator

- a multiplier cylinder and

- a cylinder positioning cylinder

How to control aluminum die casting speed?

These components make it possible to modulate the speed of the injection piston in 3 phases. Thanks to the aluminum die casting manufacturer & rapid prototyping during filling. It also includes metal compaction using the multiplier accumulator.

Modern systems allow precise control of the speed curve. Moreover, it also carries a gradual transition between approach and filling speed.

The closure unit is composed of a movable plate. It contains the ejection system. In addition, it carries a fixed plate. Here the coupling with the injection unit locates.

A closing system consisting of toggle levers is used to apply the closing force to the machine plates. This closing force must be greater than the force exerted by the metal.

The force exerted by the metal is calculated according to the following formula:

F = P int * A

- F is the force exerted by the metal

- P int is the intensifying pressure and

- A is the projected area of the part

Typically, it is recommended to have a closing force. It should be at least 20% greater than the opening force exerted by the metal. Aluminum die casting manufacturer & rapid prototyping makes the press with a solid frame.

Moreover, he ensures alignment of the movable and fixed platens by four rigid columns. These columns are placed in tension under the effect of the closing system. They must carry well balance to promote uniform application of the closing force.

The press is equipped with peripheral connections. These connections consist of:

- systems of the mold

- cylinder and injection piston

- liquid metal dosing

- automatic mold lubrication

- air draft, programmable logic controller

- interfaces operation and security elements

How does aluminum die casting manufacturer & rapid prototyping control injection cycle?

The press can also contain to a system for acquiring data. Moreover, aluminum die casting manufacturer & rapid prototyping use it to control the injection cycle in real time. Rapid response sensors measure the pressure and position of the injection piston.

It occurs almost instantaneously with feedback to keep parameters within pre-set ranges. The information can be recorded for statistical quality control.

What is the role of lubricant in molding?

The lubricant is used to facilitate demolding and to cool the mold. However, this practice tends to be minimized. Because of the greater availability of simulation software. We use lubricant and optimizing cycle time.

The lubricant applied to the mold between injections is 100% liquid. It does not contain any ceramic suspension. Similarly, it does not affect dimensional tolerances. It is applied manually or, more often, automatically.

The thermo regulation system consists of a mold heater. It has heat transfer fluid. Subsequently, it also serves to cool the mold. This can also be connected to a sophisticated temperature acquisition system.

The cell can contain a water pan to quench the parts. The production cell can be fully robotized from loading the holding furnace

Aluminum die casting manufacturer & rapid prototyping tooling design

The aluminum die casting manufacturer & rapid prototyping is responsible for the design of the mold. It includes the following features:

- Design of drawer cores for complex cavities

- Added draft angles

- Design of the feed system

- Design of the ejection system

The modeling of the filling and the solidification is widely used for the design of the die-cast molds. Subsequently, it is due to the high costs of modification of the tools.

A part design suitable for the foundry from the start increases the degree of success. You can do it by putting a part into production by die casting.

In general, you should:

- Use uniform thin sections

- Avoid isolated metal masses away from supply channels

- Use radii and limit sharp angles

- Use ribs instead of solid walls

- Take into account the demoulding axis and

- the associated loss of design degree of freedom

Take into account associated tolerances above and below the mold that are not molded together

Expect the cast to have draft angles and be marked by the ejection rods.

Advantages and Capabilities of Die Casting

Aluminum die casting manufacturer & rapid prototyping offers the best dimensional tolerances among the casting processes. Fine details and small cavities can be cast as well as fine identification lettering.

Die-casting is characterized by the possibility of molding parts. Furthermore, it has thin walls up to 1.5 mm, surrounded by reinforcing ribs. The surface finish is excellent. Moreover, 60 micro inches RMS is easily obtained. But a value of 90 micro inches RMS is more conservative.

Generally, it is possible to make structural parts. Thanks to the fine structure due to rapid cooling. It helps the use of vacuum and primary alloys with low iron content.

It is also possible to install inserts in the mold. Therefore, aluminum die casting manufacturer & rapid prototyping perform over molding. Steel is its obvious example.

The process has certain ecological advantages. Such as:

- The elimination of sand molds

- the possibility of using recycled alloys and

- the minimum of finishing after molding

The very high pressure of the metal excludes the use of sand cores. If a metal core is used in another axis, this one must resist the thrust of the metal. Therefore be assisted by a more powerful hydraulic system.

Aluminum die casting manufacturer & rapid prototyping therefore try to avoid the use of cores. Otherwise, we use a core which is ejected with the part and removed after casting.

Note the use of the salt core for complex cavities. Similarly, it is then removed by cleaning with water.