6 가지 주요 알루미늄 다이캐스팅 제조업체 유형 (2020 년 9 월)

다이캐스팅 공정을 이해하기위한 단계별 가이드 : 다이캐스팅 알루미늄

알루미늄 다이캐스팅 제조업체 소개

The low melting point of 알루미늄 다이캐스팅 제조업체 으로 인해 주조 부품을 만들기 위해 강철로 만들어진 영구 금형을 사용할 수 있습니다.

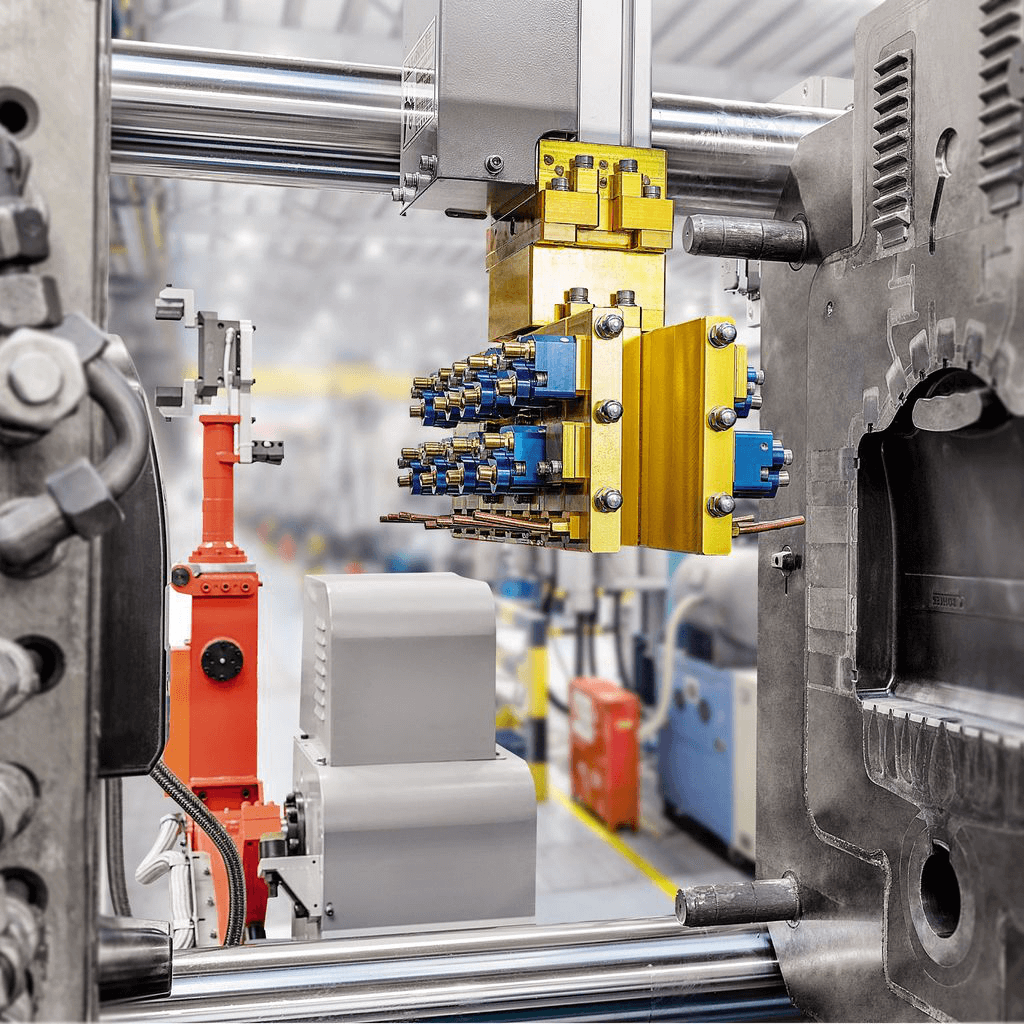

In die casting, an injection piston pushes the liquid aluminum into the mold cavity and then compresses the part during solidification. Typically, liquid metal reaches attack speeds of up to 60 meters per second. And the pressure applied can reach up to 800 bar during solidification.

To contain the pressure exerted on the part, the mold press keeps the mold closed by a closing force. It depends on the size of the indentation and the pressure applied by the piston. The smallest presses have a capacity of 1000 kN and the larger ones 35000 kN (3500 T). The force of the press is therefore directly related to the projected surface of the molded part.

The 알루미늄 다이캐스팅 제조업체 process is divided into 6 phases:

- liquid metal transfer

- injection approach phase

- rapid injection

- intensification

- ejection and

- mold lubrication.

Each phase is optimized to maximize the production rate and minimize the number of rejected parts.

There are three variants of 알루미늄 다이캐스팅 제조업체 process:

- 알루미늄 다이캐스팅 제조업체

- Vacuum die casting including vacuum casting for structural applications

- Semi solid die-casting, much less common.

Biggest advantage of aluminum die casting

The main advantage of the 알루미늄 다이캐스팅 제조업체 process is the rapid rate. It makes it possible to lower production costs and to approach mass markets such as the automobile.

The rapid cooling provided by the metal mold produces a very fine metallurgical structure on the surface called a skin. It contributes to obtaining good mechanical properties.

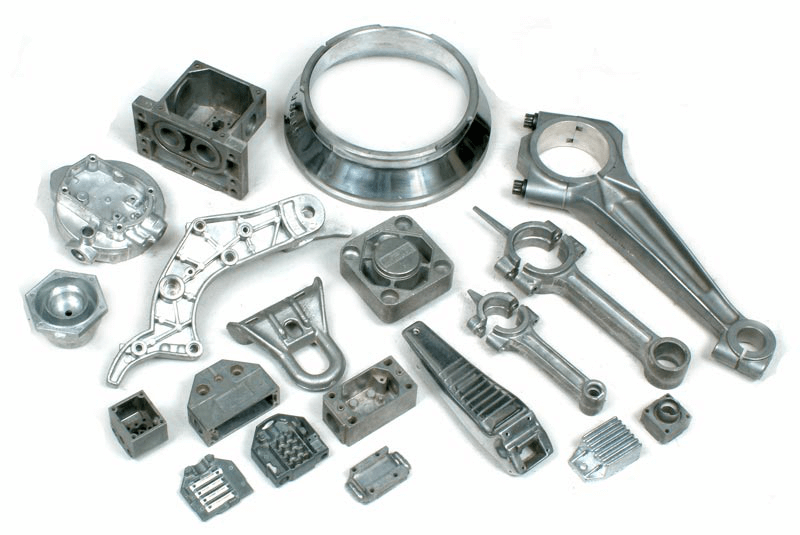

표면 마감 및 치수 공차가 우수합니다. 반면에 설계 자유는 부품의 경우 금형의 개방 축으로 실질적으로 제한됩니다. 이 과정은 노동력이 거의 필요하지 않지만 고정 및 도구 비용이 들었습니다. 10,000 개 이상의 부품을 대량으로 실행하는 경우 알루미늄 다이캐스팅 제조업체 프로세스는 파운드리 프로세스 중 부품 당 가장 낮은 생산 비용을 제공합니다.

알루미늄 다이캐스팅 제조업체는 어떻게 작동합니까?

캐비티의 진공을 사용하여 갇힌 공기의 존재를 줄이고 성형주기를 실시간으로 제어함으로써 매우 우수한 부품 품질을 얻을 수 있습니다. 고진공 압력 공정 (<50mbar)은 철 함량이 낮은 1 차 합금 (첫 번째 용융)의 개발과 결합되었습니다.

It allows to obtain a maximum elongation at break and makes the heat treatment possible for the parts dedicated to structural applications. These developments are motivated by the weight reduction of land vehicles.

And vacuum die casting provides the ideal solution of a high-speed casting process for structural parts cast in aluminum. The development of this process and of dedicated alloys is currently the most active in the field of foundry.

Elements of a mold and production cell

The 알루미늄 다이캐스팅 제조업체 process is divided into two principles of supplying the liquid metal:

- hot room technology and

- cold room technology.

The hot chamber process uses a piston directly in the bath of molten metal to feed the mold. Similarly, the cold chamber process uses a “cold” container. In this, the liquid metal is transferred by ladle or by a dosing robot. required to fill the room. Since steel is dissolved by aluminum, the production of die-cast aluminum parts is only done in a cold room.

2.1 Description of aluminum die casting manufacturer

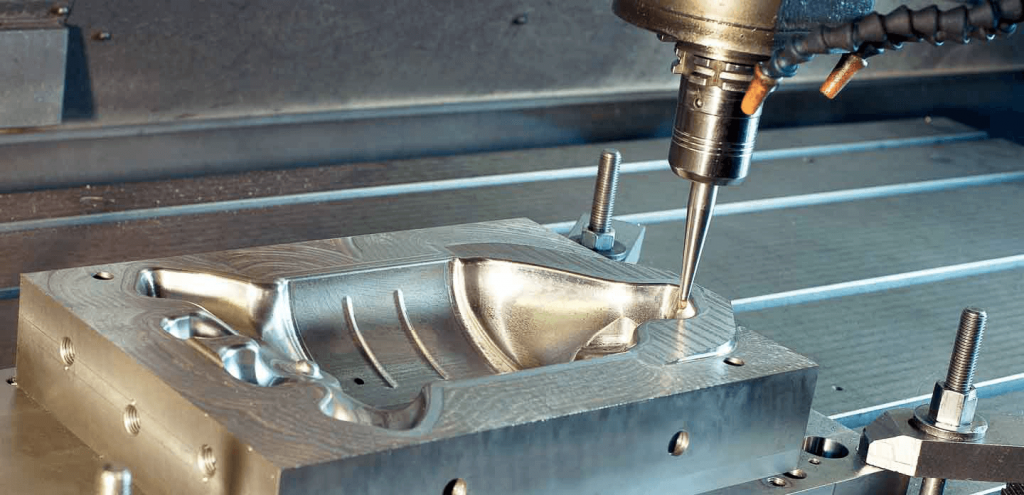

In most cases, the pressure mold consists of two metallic shells made of a ferrous alloy. Depending on the number of pieces provided, the materials used for the manufacture of the shells are:

- H13 type tool steel for indentations

- Type 4140 alloy steel or P20 tool steel for the support parts

Ejector rods are always made with a harder material. And in some cases, they are surface treated to limit sticking of the aluminum.

The 알루미늄 다이캐스팅 제조업체 composed the mold with a fixed part on the side of the liquid metal supply and a movable part on the other. The fixed part contains the metal entry hole and part of the coin cavity.

It can also have cores (fixed or drawer) to mold cavities in the part. The mobile part contains the ejection rods used for demoulding in addition to the cores and the part impression. The molds are equipped with oil (heated) or water-cooling channels. They also serve to preheat the mold initially in the case of hot oil.

How to reduce tooling cost of die casting mold?

To reduce tooling costs of 알루미늄 다이캐스팅 제조업체, the cavity often consists of a main insert placed in a larger. It is a kind of permanent frame that can produce more than one type of part. The inserts or molds typically belong to the customer.

The process is well suited for thin walls down to 1.5mm. It is preferable to use uniform sections which solidify simultaneously.

There are no weights and the attacks on the parts are small to facilitate cutting on deburring presses after casting. The design of the parts makes extensive use of the ribs to increase rigidity and mechanical strength.

It also helps fill the cavity quickly before the alloy solidifies and to vent gases. The turbulence of the metal in the cavity is controlled by:

- the speed of metal injection

- the size and positioning of the feed channels and attacks

- the shape of the cavity (mainly ribs),

- and the use of wash heels

These are used to balance the movement of the metal and to capture the inclusions formed during filling. In the case of vacuum, the vacuum application parameters are also important for filling.

Die casting mold Tooling design

알루미늄 다이캐스팅 제조업체 is responsible for the design of the mold which includes the following features:

- Added foundry shrinkage, as liquid aluminum contracts upon solidification and in solid-state. Therefore contraction of the liquid before solidification is usually compensated for by the intensifying pressure.

- Added draft angles that allow the part to be ejected.

- 응고를 시작하기 전에 최소 난류로 발자국을 채우도록 계산 된 공급 시스템의 설계.

- 배출 시스템의 설계.

- 복잡한 캐비티를위한 드로어 코어 설계.

충진 및 응고의 모델링은 공구 수정 비용이 높기 때문에 다이 캐스트 금형 설계에 널리 사용됩니다.

알루미늄 다이캐스팅 제조업체 시장

요약하면 알루미늄 다이캐스팅 제조업체 process offers the following characteristics:

- 대형 시리즈의 최저 가격

- 우수한 치수 공차 및 표면 마감

- 성형 후 필요한 최소 가공

- 2 축에서 설계 자유도가 제한된 부품

- 다양한 합금 선택 가능

전통적인 다이캐스팅 시장은 생산 부품에 초점을 맞추고 있습니다. 소규모 하드웨어 산업, 패스너, 하우징, 자동차 부품이 주요 지원자입니다.