10 mẹo hàng đầu của Nhà sản xuất khuôn cho khuôn nhựa (Tháng 9 năm 2020)

Làm thế nào để nhà sản xuất khuôn tạo ra một khuôn thạch cao chất lượng?

Bạn có muốn tìm hiểu những điều cơ bản về nhà sản xuất khuôn tạo ? Có lẽ bạn đã bắt đầu đúc một vài miếng thạch cao trong xưởng của mình để làm các món ăn bằng sứ, đồ đá hoặc đất nung? Hay bạn đang phát triển một dự án điêu khắc hơn?

Have you encountered any difficulties with the use of your plaster or the resistance of your molds? If there is one element that should not be overlooked in appreciating the casting process, it is the quality of the plaster.

Practical steps for a successful mold

To obtain a good mold, like nhà sản xuất khuôn tạo, it is necessary to anticipate the stages of its project. We will review together the preparatory phases for the manufacture of a plaster mold. The right questions to ask before production and how to choose a quality plaster.

The steps to make a piece of porcelain

First of all, the first thing to do when you want to make a ceramic part is to create your model.

Using a drawing representing the part at the desired size. The modeler must anticipate the shrinkage that the part will undergo during firing. For this, the modeler will create his mold with a volume of plaster larger than the actual size of the part. It is estimated at + 14%.

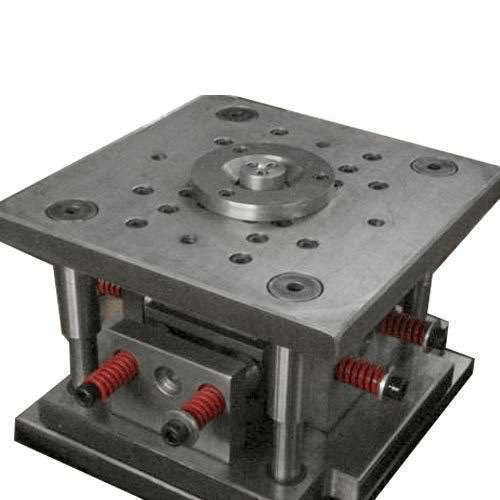

This created model is called the mother nhà sản xuất khuôn tạo. It will be used to make production molds called matrices.

The dies are the molds that will make it possible to make ceramic parts, especially porcelain. They will therefore be used directly for our production.

As you can see, these two types of molds do not have the same utility, and it is very important to differentiate them.

Questions to ask nhà sản xuất khuôn tạo before starting production

Before starting a production, it is imperative to ask the following questions:

- I want to make a “mother mold” or a die?

- What object do I want to obtain in molding?

- A cafeteria?

- A vase?

- A cup?

- A plate?

At this point a professional nhà sản xuất khuôn tạo advises you to study the shape well. You can even make a small cardboard model to help you visualize the object in 3D.

Be careful not to hamper your creativity by wanting to “fit into the mold”. With time and practice you will intuitively know which shape is interesting to produce in molding.

What process will be suitable for my molding?

The casting? calibration? isostatic pressing? The modeling?

Find out about the most used molding processes in the article clay molding for beginners which describes the steps step by step.

What type of plaster will be suitable for my mold project?

Each plaster needed to make a mold has its own specific characteristics. This is why the choice of the plaster to be cast is a fundamental step before embarking on the manufacture of any ceramic part.

Choose a quality plaster nhà sản xuất khuôn tạo

There are many plasters nhà sản xuất khuôn tạo but some are suitable for ceramics. So, don’t go looking for a random cast at the local DIY store.

You should know that plaster is initially a very volatile powder composed of gypsum. Its manufacturing process makes it permanently porous. When it is mixed with water, a chemical reaction is created.

It causes it to harden, this is called “plaster setting”. This preparation can be facilitated if one is familiar with the procedures to follow, but also according to the quality of the plaster.

Versatility of mold

In ceramic, we choose to use plaster because it is a very versatile material, as it is tender, it can be sculpted at will. One can obtain surfaces while texture or conversely t smooth almost, complex or otherwise of great simplicity. We therefore need a m flexible job material for creating different types of art pieces.

The precision of the mold

It is also interesting for nhà sản xuất khuôn tạo to work the finish molds by hand with precision. A quality plaster has a fine grain with few impurities. It must ensure a perfect reproduction of details. It must be pleasant to work with, whether you dig it, smooth it, sand it, etc.

Durability

We also want our mold to be sustainable. That we can handle it for several years without it getting damaged too quickly. Because making molds can take a long time, and requires great care. We don’t want to start over every 6 months!

However, plaster remains a friable material. That is why a great resistance and toughness is desired as well as stability in the product quality.

10 tips for perfect nhà sản xuất khuôn tạo

- Ensure optimal working environment conditions: T ° of 22 ° C and relative humidity less than 60%.

- Make a perfect model or matrix effectively sealed to avoid any porosity. If necessary, apply a sealant.

- Use a high-quality release agent that is perfectly compatible with the resin used.

- Choose an appropriate rigid or elastomeric molding system based on the part to be cast. Evaluate your need for a release agent and select it according to the part.

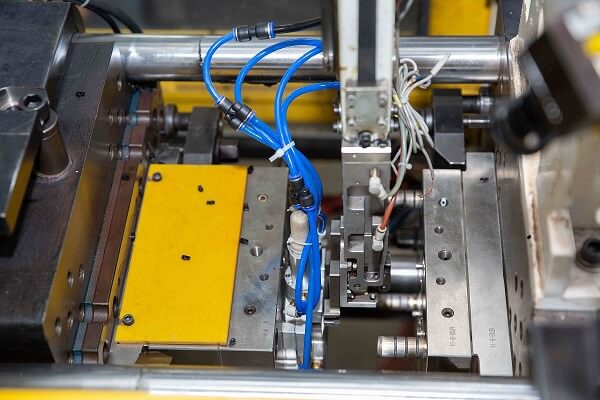

- Một máy nhà sản xuất khuôn tạoshould thoroughly disperse the materials of each container separately.

- Observe precisely the mixing ratio of parts A and B by weight or volume as indicated in your supplier’s technical sheet.

- Make a perfectly homogeneous mixture of parts A and B. Polymerization can only be carried out completely after having carefully and long insisted

- Perform a fine casting at a strategic point according to the design of the part.

- Wait for complete polymerization of the mold on the model before starting the demoulding.

10.Do not neglect the regular maintenance of the mold in order to avoid a build-up of release agent.

If you don’t know

Bạn có nghi ngờ hoặc bạn nghĩ rằng bạn đã làm theo tất cả các bước này, nhưng khuôn của bạn không đáp ứng mong đợi của bạn? Kaitomould chắc chắn sẽ có câu trả lời.

Kết luận

Tôi hy vọng rằng những tiêu chí này sẽ cho phép bạn thực hiện những vai diễn đáp ứng được mong đợi của mình. Tất nhiên, thực hành đúc không thể ngẫu hứng với một nhà sản xuất khuôn tạo . Quy trình bao gồm các bước được quan sát. Nhưng một chiếc khuôn, thậm chí rất đơn giản, đã có thể mang lại rất nhiều hứng thú cho việc sản xuất của bạn! Vì vậy, đừng ngần ngại bắt đầu!