Top 10 Formen Hersteller Tipps für Kunststoffformen (Sept. 2020)

Wie stellt der Formenhersteller eine hochwertige Gipsform her?

Möchten Sie die Grundlagen des Formenhersteller? Vielleicht haben Sie bereits begonnen, in Ihrer Werkstatt einige Stücke zu verputzen, um Porzellan, Steinzeug oder Steingutgeschirr herzustellen? Oder entwickeln Sie ein skulpturaleres Projekt?

Haben Sie Schwierigkeiten mit der Verwendung Ihres Putzes oder der Beständigkeit Ihrer Schimmelpilze ? Wenn es ein Element gibt, das bei der Beurteilung des Gießprozesses nicht übersehen werden sollte, dann ist es die Qualität des Putzes.

Praktische Schritte für eine erfolgreiche Form

Um eine gute Form wie den Formenhersteller , ist es notwendig, die Phasen seines Projekts vorwegzunehmen. Wir werden gemeinsam die Vorbereitungsphasen für die Herstellung einer Gipsform überprüfen. Die richtigen Fragen vor der Produktion und die Auswahl eines Qualitätsputzes.

Die Schritte, um ein Stück Porzellan zu machen

Wenn Sie ein Keramikteil herstellen möchten, müssen Sie zunächst Ihr Modell erstellen.

Using a drawing representing the part at the desired size. The modeler must anticipate the shrinkage that the part will undergo during firing. For this, the modeler will create his mold with a volume of plaster larger than the actual size of the part. It is estimated at + 14%.

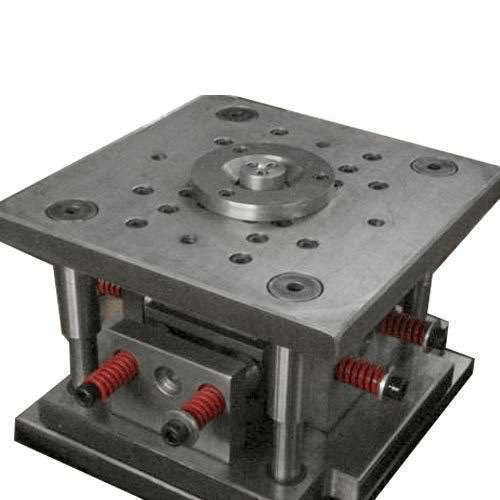

This created model is called the mother Formenhersteller. It will be used to make production molds called matrices.

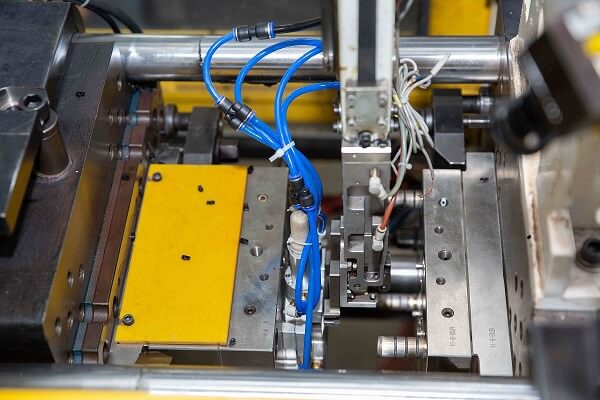

The dies are the molds that will make it possible to make ceramic parts, especially porcelain. They will therefore be used directly for our production.

As you can see, these two types of molds do not have the same utility, and it is very important to differentiate them.

Questions to ask Formenhersteller before starting production

Before starting a production, it is imperative to ask the following questions:

- I want to make a “mother mold” or a die?

- What object do I want to obtain in molding?

- A cafeteria?

- A vase?

- A cup?

- A plate?

At this point a professional Formenhersteller advises you to study the shape well. You can even make a small cardboard model to help you visualize the object in 3D.

Be careful not to hamper your creativity by wanting to “fit into the mold”. With time and practice you will intuitively know which shape is interesting to produce in molding.

What process will be suitable for my molding?

The casting? calibration? isostatic pressing? The modeling?

Find out about the most used molding processes in the article clay molding for beginners which describes the steps step by step.

What type of plaster will be suitable for my mold project?

Each plaster needed to make a mold has its own specific characteristics. This is why the choice of the plaster to be cast is a fundamental step before embarking on the manufacture of any ceramic part.

Choose a quality plaster Formenhersteller

There are many plasters Formenhersteller but some are suitable for ceramics. So, don’t go looking for a random cast at the local DIY store.

You should know that plaster is initially a very volatile powder composed of gypsum. Its manufacturing process makes it permanently porous. When it is mixed with water, a chemical reaction is created.

It causes it to harden, this is called “plaster setting”. This preparation can be facilitated if one is familiar with the procedures to follow, but also according to the quality of the plaster.

Versatility of mold

Bei Keramik verwenden wir Gips, da es sich um ein sehr vielseitiges Material handelt, da es zart ist und nach Belieben geformt werden kann. Man kann Oberflächen erhalten, während die Textur oder umgekehrt fast glatt, komplex oder auf andere Weise von großer Einfachheit ist. Wir brauchen daher ein flexibles Arbeitsmaterial, um verschiedene Arten von Kunstwerken zu schaffen.

Die Präzision der Form

Für den Formenhersteller , die Oberflächenformen . Ein Qualitätsputz hat eine feine Maserung mit wenigen Verunreinigungen. Es muss eine perfekte Reproduktion von Details gewährleisten. Es muss angenehm sein, damit zu arbeiten, ob Sie es graben, glätten, schleifen usw.

Haltbarkeit

We also want our mold to be sustainable. That we can handle it for several years without it getting damaged too quickly. Because making molds can take a long time, and requires great care. We don’t want to start over every 6 months!

However, plaster remains a friable material. That is why a great resistance and toughness is desired as well as stability in the product quality.

10 tips for perfect Formenhersteller

- Ensure optimal working environment conditions: T ° of 22 ° C and relative humidity less than 60%.

- Make a perfect model or matrix effectively sealed to avoid any porosity. If necessary, apply a sealant.

- Use a high-quality release agent that is perfectly compatible with the resin used.

- Choose an appropriate rigid or elastomeric molding system based on the part to be cast. Evaluate your need for a release agent and select it according to the part.

- A Formenherstellershould thoroughly disperse the materials of each container separately.

- Observe precisely the mixing ratio of parts A and B by weight or volume as indicated in your supplier’s technical sheet.

- Make a perfectly homogeneous mixture of parts A and B. Polymerization can only be carried out completely after having carefully and long insisted

- Perform a fine casting at a strategic point according to the design of the part.

- Wait for complete polymerization of the mold on the model before starting the demoulding.

10.Do not neglect the regular maintenance of the mold in order to avoid a build-up of release agent.

If you don’t know

Do you have any doubts or do you think you have followed all these steps, but your mold does not meet your expectations? Kaitomould certainly have the answer.

Conclusion

I hope that these criteria will allow you to perform casts that meet your expectations. Of course, the practice of molding cannot be improvised with a Formenhersteller. The process includes steps to be observed. But a single mold, even very simple, can already bring a lot of interest to your production! So, don’t hesitate to get started!