Ways In Which 3D Rapid Prototype Printing Improves Prototyping

Ways In Which 3D Rapid Prototype Printing Improves Prototyping

5 Ways to Enhance Prototyping Using 3D Rapid Prototyping

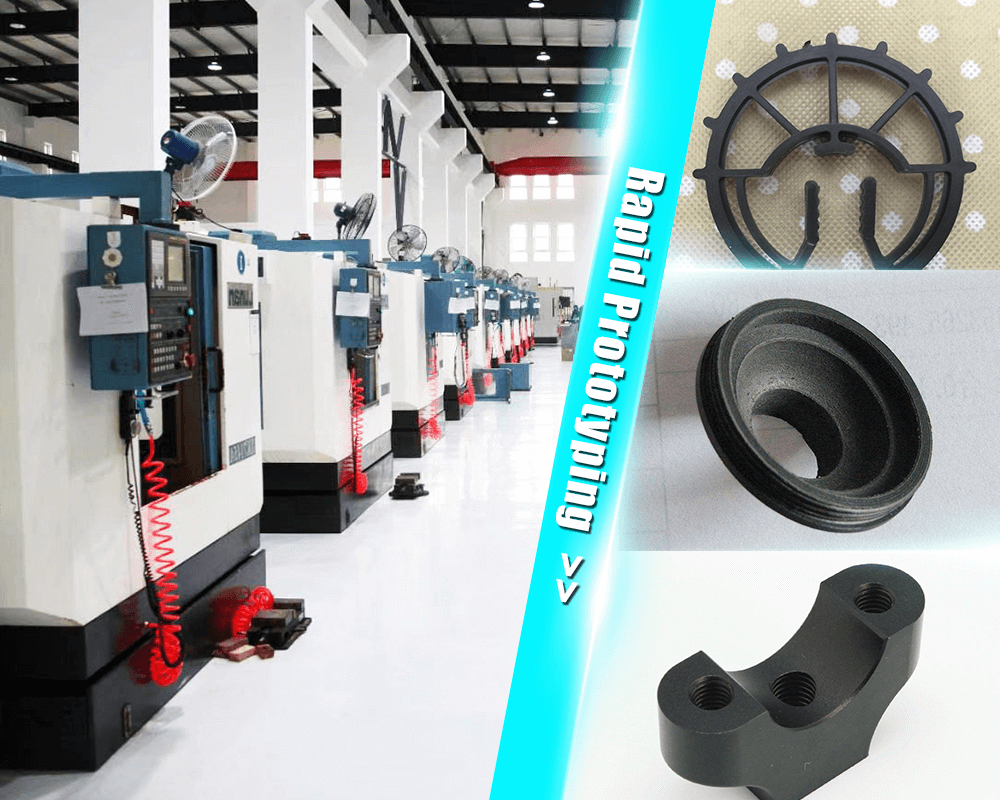

In addition to being affordable, the technology offers diversity in terms of development and technique. Designers and engineers are able to think out of the box. They have the power to create some of the most complex and complicated parts and components.

To use the technology to its full potential, you need to have a basic understanding of 3D rapid prototyping and its different printing techniques. Therefore, we will provide you with information regarding these two concepts in our blog post.

The 3D Rapid Prototype Technology Has to Offer?

Below, we have listed the 5 different ways that will help you create high-quality prototypes. These methods would ensure that your current manufacturing is different from conventional ones. After all, 3D printing did enhance the product design and development phase. It has made it a more refined and sophisticated technique.

Better Design

For years, manufacturers have been using prototypes to the validity of their design. However, there is a mark difference between those prototypes and the modern 3D prototypes. Today’s prototypes offer endless opportunities, it has more room for flexibility at every stage of the prototyping process.

All this is possible because of 3D printing technology. Instead of relying on distinct stages that relied on digital models, modern 3D printing techniques come with no limitation. Also, conventional prototypes were nothing near the final product.

They lacked the functionality factor as well as the feel and look of the final product. However, with 3D printing, you can achieve premium quality, fully functional prototypes in no time. With 3D printing, it is possible to create prototypes within hours instead of days or months.

Manufacturing as a Service

Since the boost in the software industry, we have been hearing about the term “Saas” – Software as a Service. But it seems that the same concept is growing in the 3D industry as for majorly because of 3D printing technology.

Currently, the market trend shows that there are several companies with infrastructure built that are supporting different production and design efforts for their diversity clientage. They are able to achieve all this by using 3D printing technology.

It seems that organizations that offer rapid tooling services are and will be an important part of the manufacturing industry’s future. You will be surprised to know that a lot of resources are available online for your better understanding of the concept and its benefits.

The technology would ensure that the manufacturers are able to update and upgrade their product or application seamlessly without wasting critical time.

Less Material Wastage in 3D Rapid Prototyping

Due to the rapidly changing environmental conditions, every industry is trying to reduce carbon footprint and decrease their waste ratio. Moreover, governments around the globe now have very strict rules regarding material waste.

Fortunately, the 3D rapid prototype printing techniques decrease the material waste ratio significantly. At the same time, it ensures efficiency and reliability. Something every manufacturer is looking forward too.

Statistics show that on average a conventional manufacturing company wastes roughly 21 percent of the material. However, in the case of rapid prototyping 3D printing, material waste is below 10 percent. Moreover, the amazing technology would reduce carbon emissions drastically.

This is something that every manufacturer needs to incorporate. Although 3D printing is currently limited to prototyping, it has a bright future. It would become the center of the manufacturing as well as other industries.

Higher Utilization

The manufacturing processes are among the least efficient methods. According to research, the manufacturing companies’ utilization is 75 percent. The statistics are true for the USA alone. Imagine the waste percentage worldwide.

This percentage indicates that ¼ of the methods and materials are not used efficiently. These things are going to waste. The reason being, traditional manufacturing methods rely on techniques like die casting and injection molding. These systems do not have the flexibility and the versatility a 3D printing system would offer.

For instance, a 3D printer has the ability to print twenty different types of applications or parts. Manufacturers are able to develop different products using the same printer. Thus, it eliminates the need for system switching.

This is a big development for the manufacturing industry in terms of higher utilization.

Rapid Prototyping Encourages Innovation

With rapid 3D printing, designers and developers have no limitations. It seems that the sky is the limit. They are able to come up with unique out of the box idea, test them at minimal cost, and see if they stand corrected.

The 3D rapid prototype printing encourages innovation. Unlike conventional methods, where manufacturers created different parts separately and compile them in the end. This led to a number of restrictions.

Manufacturers are not able to see this particular issue in the case of 3D printing. The technology effortlessly removes such constraints. Thus, allowing you to come up with valuable, yet complex products without requiring other design elements.

The technology offers the freedom to think, as there are almost no constraints when it comes to creating functional, effective, and affordable prototypes. It is now possible for the developers to create further on the complex solutions using a single machine.

A great example of 3D printing is the printing of medical devices. Ranging from the titanium skull plates to several other breakthroughs, the industry is now greatly dependent upon 3D rapid prototype for innovation.

The Future Challenges

The constant development of technology has helped in overcoming several changes. However, manufacturers are now acknowledging new challenges. The most prominent one is that the high cost of 3D rapid prototype printing material and tools.

This is perhaps the major reason why manufacturers are not fully incorporating 3D printing for large scale production. We are hoping that further research and development would lead to cheaper alternatives.

Top-Notch 3D Rapid Prototyping Service Provider

Kaito Mould is among the best rapid prototyping service provider. There years of experience and an extremely skilled team allows them to make the impossible, possible. Contact Us Today for more