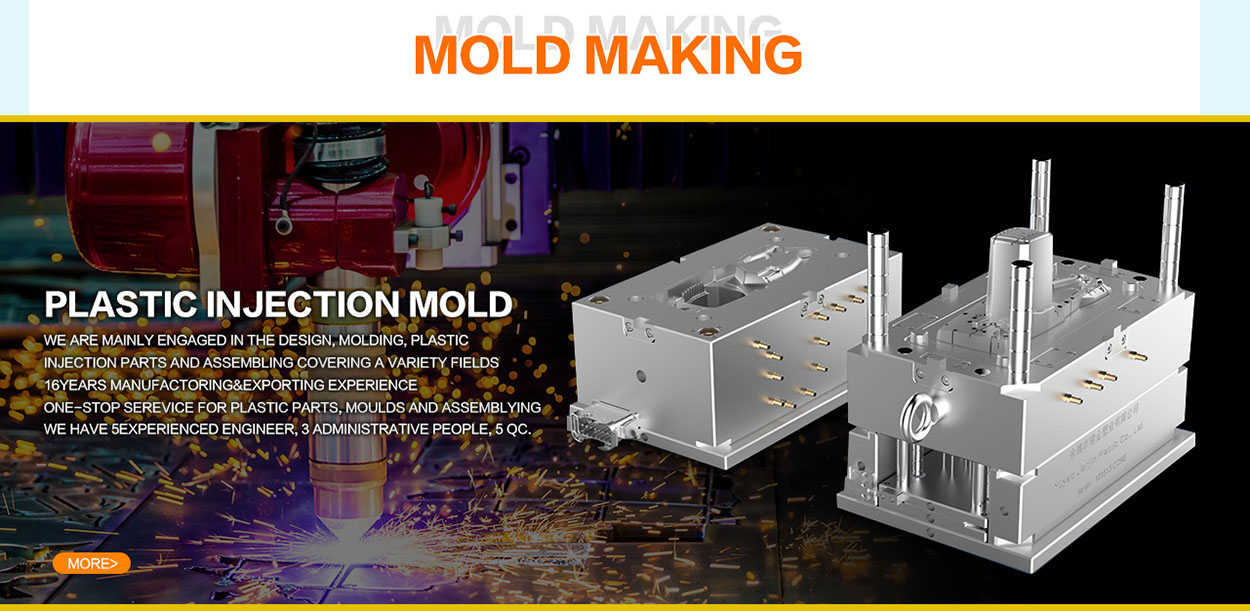

CETAKAN INJEKSI PLASTIK

CETAKAN INJEKSI PLASTIK UNTUK PRODUKSI BAGIAN PRESISI

Injection moulding adalah sebutan untuk proses yang digunakan dalam pengolahan plastik. Ini memungkinkan produksi suku cadang dengan ukuran berbeda yang secara tepat disesuaikan dengan dimensi yang ditentukan. Perusahaan kami menggunakan mesin dan sistem canggih untuk cetakan injeksi plastik, yang juga dirancang untuk pemanfaatan tinggi. Pencetakan injeksi dimungkinkan karena plastik dapat bengkok saat dipanaskan. Dimungkinkan juga untuk mencairkannya. Kedua varian tersebut digunakan dalam pengolahan plastik modern.

BAHAN VERSATIL UNTUK PENGOLAHAN PLASTIK

Plastik adalah bahan yang digunakan dengan berbagai cara. Penggunaan fleksibel ini dimungkinkan karena sifat dari plastik memungkinkan untuk digunakan di luar ruangan dan di dalam ruangan. Di banyak perusahaan, plastik menjadi sangat diperlukan. Bahannya bisa digunakan di area basah atau di luar ruangan selama bertahun-tahun. Hujan dan basah tidak memengaruhi plastik. Hanya warna yang menjadi lebih terang dari waktu ke waktu. Mereka memudar di bawah sinar matahari. Jika plastik sangat keras, permukaan dapat menjadi keropos seiring waktu. Ini harus diingat jika plastik akan dibuat untuk penggunaan permanen di luar ruangan dan tidak ada perlindungan cuaca. Obatnya adalah dengan menggunakan plastik yang lebih lembut. Sinar matahari langsung membuat bahan yang lebih lembut tidak terlalu lembut

Produksi Inovatif Berkelanjutan - Cetakan Injeksi Plastik

Plastic is robust and malleable. The material convinces with a low weight. It can swim over water or be used under water. As an important part of machines and systems, plastic impresses with its versatility. This is not least due to the injection molding process. This process also allows the production of very unusual shapes that deviate from classic symmetry. And there are other positive characteristics. Plastic is available in many different colors.

“We aim to Enrich your business and plastic solutions”

The color nuances are helpful when differentiations between individual parts or components have to be made. In some areas, color adjustments to the original are required. This is the case, for example, in dental technology. Dentures, no matter what type, wanted to be anchored in the jaw as inconspicuously as possible. The dentist uses color charts for this because the teeth of humans differ in the smallest color deviations. In plastics processing, it is possible to use the exact color of natural teeth for dentures. In this way, the dentures remain invisible when worn.

INDIVIDUAL ADVICE FOR OUR CUSTOMERS

We offer you comprehensive packages for the production of parts from plastic injection molding. When it comes to injection molding, we give great importance to the precise execution of all work. The accuracy of fit is a guarantee.

We manufacture plastic by injection molding and use materials that meet the requirements for later use without restrictions. Let our company manufacture precision parts for mechanical and plant engineering, for the auto industry or for handicrafts and trades. We offer you individual advice on the possibilities offered by injection molding. The satisfaction of our customers is priority, and so our experienced employees carry out every order in accordance with standards. Remain satisfy and send us your request.

“We would be happy to advise you on the implementation of your innovative ideas, convince you with new shapes and state-of-the-art materials that withstand all criteria such as environmental friendliness, sustainability and extreme stress.”

MODERN MANUFACTURING AND IN-DEPTH FIELD KNOWLEDGE

support and check your items from the technical draft to later series production.

We are solution developer for large series in the field of plastic injection molding. We support medium-sized companies as well as global players from many industries with a non-ultra-complete package consisting of inspiration, innovation and implementation for more competitive advantage and success.

Our employees develop and manufacture plastic parts for various applications and customers from the construction industry, components for electrotechnical products and plant engineering, chairs & furniture, household and the transport & packaging industry.

Jika kami dapat membantu Anda dengan proyek Anda, hubungi kami di 0086-769-82821468 atau email sales@kaitomould.com