자동차

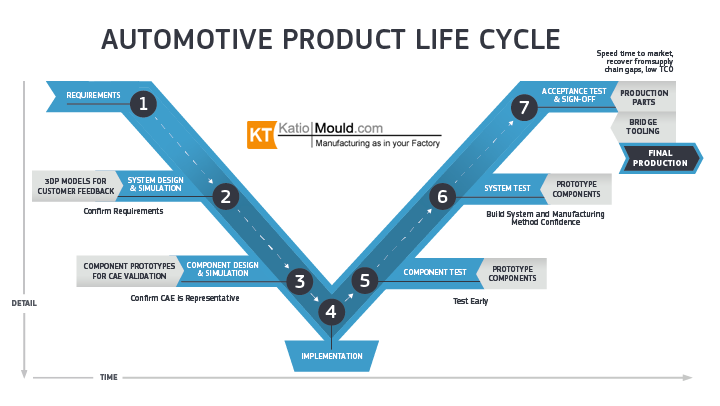

자동차 산업은 빠르게 진화하고 있습니다. 자율 주행, 온보드 연결, 하이브리드 / 전기 자동차와 같은 산업 트렌드가 계속해서 혁신을 주도함에 따라 민첩성을 추구하는 자동차 회사는 신제품 개발을 가속화하고 시장에 더 빨리 진출하기 위해 Protolabs로 전환하고 있습니다. 퀵턴 디지털 제조 및 자동화 된 제조 가능성 피드백을 통해 설계자와 엔지니어는 설계 및 비용 위험을 완화하는 동시에보다 응답 성이 뛰어난 공급망을 개발하여보다 맞춤화 된 차량에 대한 운전자 및 승객 수요에 더 잘 대응할 수 있습니다.

Why kaitomould for Automotive Development?

신속한 프로토 타입

Mitigate design risk through rapid iteration and prototyping in production materials without sacrificing development speed.

Supply Chain Flexibility

Get on-demand support for line-down emergencies, part recalls, or other supply chain disturbances in your production plants by using automated quoting, rapid tooling, and low-volume production parts.

Quality Inspections

Validate part geometry with several quality documentation options. Digital inspection, PPAP, and FAI reporting are available.

Mass Customization

Implement low-volume manufacturing to enable more diverse and customized automotive features that are tailored to modern drivers.

Tooling and Fixtures

Improve manufacturing processes to create greater automation and streamlined component assembly with custom fixturing.

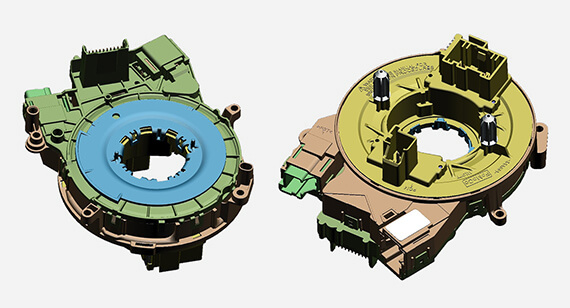

The renderings show top and bottom views of ZF’s intricate clock spring assembly.

The renderings show top and bottom views of ZF’s intricate clock spring assembly.

A Front Seat on Driving Innovation with ZF

Steering column control modules now integrate an expanding variety of functions into the steering wheel, offering drivers a host of functions for both safety and convenience. Providing connectivity between all of those helpful buttons and switches and the functions they control—from the turn signals and wipers to cruise control and even heating the steering wheel itself—is the job of the clock spring, a plastic disc about the size of a hockey puck that sits hidden under the steering wheel within the steering column control module. See how digital manufacturing helped reduce product development time for global tech companies Kaito Mould.

What Materials Work Best for Automotive Applications?

COMMON AUTOMOTIVE APPLICATIONS

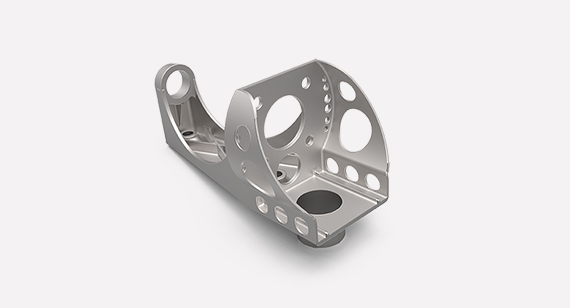

Our digital manufacturing capabilities accelerate the development of a range of metal and plastic automotive components. A few of common automotive applications include:

- Assembly line components

- Fixtures

- Enclosures and housings

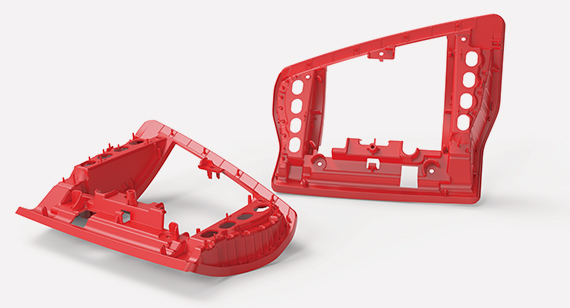

- Plastic dash components

- Aftermarket parts

- Armatures

- Lenses and lighting features

- Support for on-board consumer electronics

Click to enlarge

Click to enlarge