3D Prototype Manufacturer: A Material Recommendation Guide

3D Prototype Manufacturer: A Material Recommendation Guide

What Materials Would a 3D Prototype Manufacturer Suggest?

The choice of material is as important as the 3D prototype manufacturer. Therefore, you need to have complete information regarding the wide range of materials available for 3D printing services. Every material has its own benefits and cost.

In this course of the article, we are going to talk about the different range of materials that are available.

Introduction to Different 3D Prototype Manufacturing Materials

While choosing the right material for your product, you will have to consider the following aspects.

The Price

This is perhaps the most important phase for you. You need to look for ways to reduce the cost while improving the manufacturing process quality. For instance, if your final part needs to be of metal, creating a prototype with plastic would turn out to be eventful.

Of course, for initial prototypes, you can use plastic as it would cost you less. However, for the later or final prototypes, use the same material as the final product. In this case, it is metal. Instead of going with just one material, we recommend choosing a combination of materials to find the most optimal solution for your prototyping requirements.

Material Quality and Accuracy

The main reason for creating a prototype is to test idea validity and to find errors in it before entering the mass production phase. With a 3D prototype, you can spot the last error in the project. Doing this will give you an excellent overview of your project.

A functional prototype would help identify issues and let you know whether the idea was worth the shot or not. If you are aiming for a complex object or product, that has an elaborate design, you need to focus on the material.

Also, check the 3D printing technique, make sure that it is precise enough to assist you in achieving your goal. It is obvious that you will need to keep the mechanical properties of the material in mind as well. After all, these properties should be compatible with your application.

When you use the right material, and the correct 3D prototyping technique, you will be able to manufacturer a high-quality, accurate, and fully functional object. Some other important questions that would help you choose the correct material include:

- It is important for the prototype to have the same weight as that of the final product?

- Does the prototype need to be of the same dimensions?

- Should it have the same applications?

You need to answer all these questions before you make the final decision.

Material Design Guidelines for 3D Prototype Manufacturer

Since every material has its own guidelines, therefore, you would have to check all these guides to make the right decision. Perhaps this is the reason, why some 3D files are not 3D printable. You need to have complete knowledge as per the geometry and the dimension of the project.

Lack of proper dimensions could lead to different problems. For example, if the walls turn out to be extremely thin, the printer not might be able to print it or it might break. This would lead to counterproductive.

The Best Printing Materials

We have said this before, and we are saying this again. The choice of your 3D printing material majorly focusses on the application requirement. Below, we have come with a selection of materials that a 3D prototype manufacturer would prefer.

Nylon PA12

The first and perhaps the most common material is the Nylon PA12. The white material offers a number of mechanical properties while ensuring the affordability factor. The material is an excellent choice for both productions as well as prototyping. It is made using a fine polyamide powder.

Manufacturers would use the Selective Laser Sintering technology to create the desired components and parts. With Nylon PA12, you also have numerous options in terms of finishes and final touching. However, if you prefer the raw look, you can even have the raw parts.

In addition, to be extremely affordable, the Nylon PA12 gives freedom when it comes to geometry. It goes through several iterations.

Multi-Jet Fusion PA12

This is another amazing material for prototyping. It is grey plastic that lets you create even complex and complicated prototypes. The material is the perfect choice for both the production as well as the prototype manufacturing.

The reason being, it is extremely cheap in its raw form. You will be able to make several iterations without adding a lot to your prototype budget. A reliable 3D prototype manufacturer would recommend this product, especially when you are running low on budget, but don’t want to compromise on quality.

What more is that the objects created using Multi-Jet Fusion PA12, are suited against abrasion and scratches. Therefore, it is an excellent material for testing purposes as well. The material is lightweight, it is weather stable, U.V. stabilized. In short, is the perfect choice for prototypes that are to be tested outdoors.

Prototyping Resin

The material is the perfect choice for creating detailed and through prototypes. However, do bear in mind that it does not have the ability to create functional prototypes. The material ensures a smooth surface finish and a complete look.

The object that is created using this material is similar to the one created using the plastic injection molding technique. To create prototypes using this material, a 3D prototype manufacturer would use the stereolithography process.

PLA

Numerous manufacturers rely on the Fused Deposition modeling technique for the creation of prototypes.

NOTE: The option won’t provide you with a detailed prototype.

If you have an oversize project, it can be a good choice. However, we still recommend checking with your manufacturer before the final decision.

TPU

If you are searching for something extremely flexible while being robust, TPU is the solution. The rubber-like material is an excellent choice for creating fully functional, flexible, and sturdy prototypes.

The material would create prototypes that can resist fatigue and stress to a great extent.

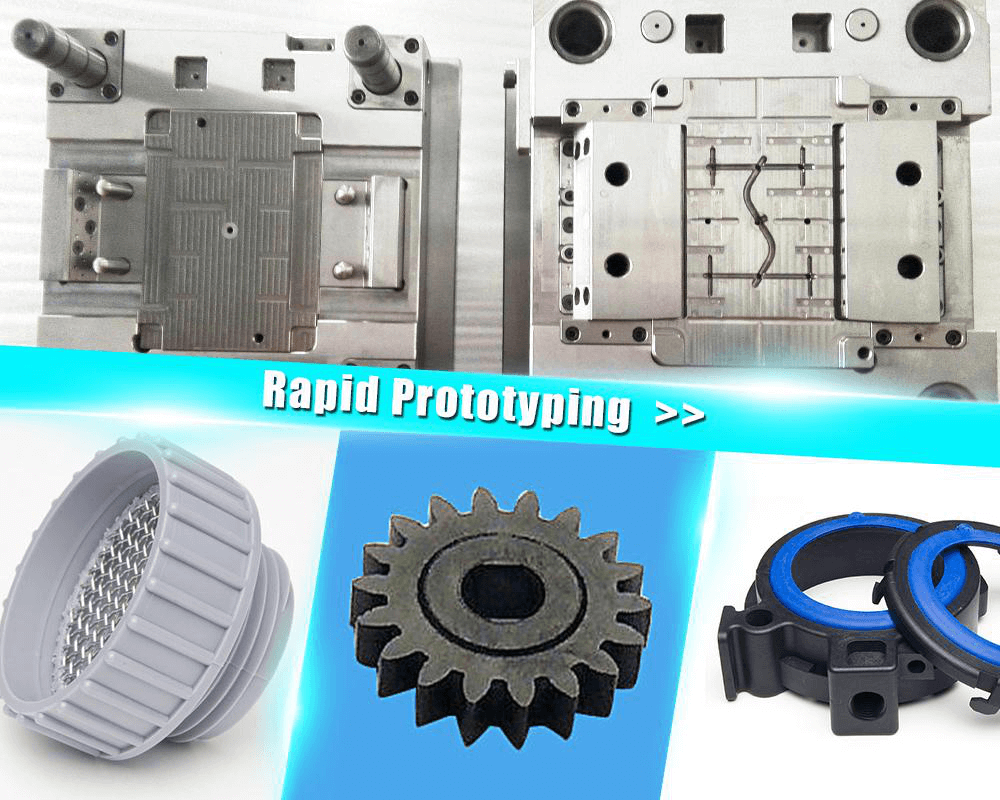

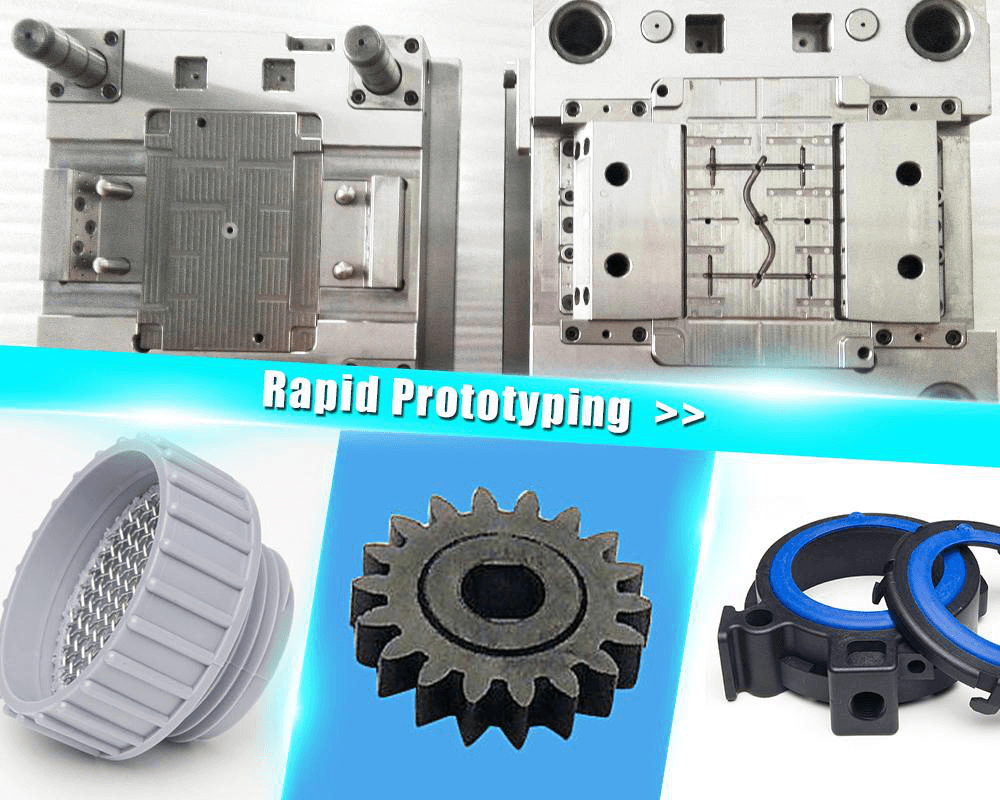

3D Prototype Manufacturer: Why US?

At Kaito Mould, we have highly skilled designers and engineers who would create high-quality, accurate, robust, and strong prototypes in no time. In addition to creating prototypes, we would provide you with complete assistance at every step, starting from idea analysis to final production.

To reach out to us today, Click Here.