What does Insider say about Chinese custom plastic parts manufacturers?

Future of custom plastic parts manufacturers industry in China

In today’s modern era custom plastic parts manufacturers have distinctive contribution. Without plastics, life is almost impossible.

The uses of plastic are very wide. In everyday life, there are countless colors and shapes of engineering plastic components. For example, in normal life we use plastic in almost everything. From the ballpoint to nuts for the car bumpers and everything in the house.

plastic injection molding in the world is one of the largest industries. So, let’s figure out the possibilities and optimal ways of molding plastic structures for various circulations and needs.

How custom plastic parts manufacturers use custom molding parts?

custom plastic parts manufacturers use engineering plastics in injection molding tools. And it is one of the formal forming processes of injection molding tools. For example, manufacturers particularly use shapeless materials to create special shapes.

The basis of injection molded parts is conventional engineering plastic particles. Similarly, manufacturers heat the initial solid particles. There is no doubt that this process is tough than its initial process.

All products which they manufacture must match appropriately. As well as accurately to its relevant technical parameters. And all the products should have similar features like:

- Color

- size and

These products must have high resistance and good quality properties too.

A short background of custom plastic parts manufacturers

The first equipment following this rule had made in 1919. And had used for the processing of soft cellulose acetate.

Many customers contact us online to order plastic products. But most people don’t know much about the plastic processing industry. And they also don’t know what the specific process for plastic products is. This is because there are unnecessary barriers to communication.

How can you get access to custom plastic parts manufacturers for your needs?

Today, I am here to describe you briefly to sort out the basic process for plastic products. And the quotation form of related products.

In fact, contacting custom plastic parts manufacturers is a very simple process. And it may not be too detailed. Everyone can understand and learn what the ordering service is all about.

Generally, there are many plastic product manufacturers. That can independently design and develop some products. But the types of products that most manufacturers can develop are very limited. In addition, they often only focus on a subdivided industry in the plastic processing industry.

Some manufacturers are pretty weak in technical strength. The reason is that their business is limited to the production of several products. And their design and R&D capabilities are also very short.

The whole process and classification of plastic mold manufacturing

Plastic mold manufacturing is the primary task of producing plastic products. Without molds, custom plastic parts manufacturers are unable to produce various plastic products.

We can say that the quality of manufacturing directly affects the quality of plastic products. Only if they have sophisticated mold manufacturing technology. They can provide customers with professional custom-made services.

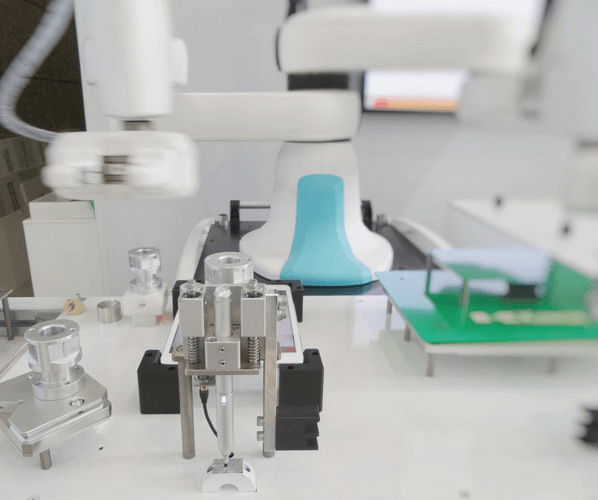

The injection molding machine usually consists of three parts:

- the machine tool

- the injection element, and

- the clamping device.

The energy supply chain system should be perfect to run all operations smoothly.

How do custom plastic parts manufacturers use machine tool for molding plastic?

Machine tools are the foundation of machinery. The distribution box is set here. And the drive integration depends on the machinery. The other two components are usually movable and located on the machine tool.

The initial stroke of the original part takes place on the injection molded component. Moreover, Custom plastic parts manufacturers heat plastics.

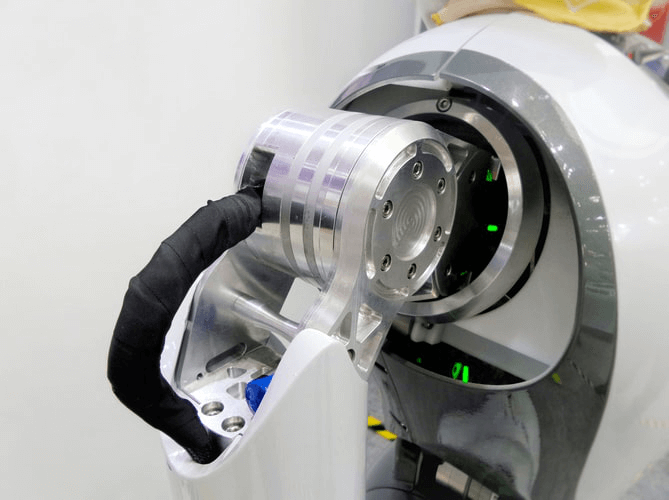

The tool of the clamping device determines the shape of the engineering plastic product. It is called a clamping device. Because the material supply of the injection-molded components can be closed and opened at the same time.

The clamping element has 2 grids for mounting metal. These fixing plates are vertically fixed in the axial direction.

How does an engineering plastic injection molding machine work?

First, set up injection molding machinery. custom plastic parts manufacturers determine which engineering plastic product needs to be replaced. Therefore, engineering plastic injection molding machines can produce many different numbers of parts.

When the machine is running, the lead screw rotates. So, the engineering plastic particles move to the front of the machine. And the heater heats the material to a liquid state.

The screw movement creates pressure. Once the production pressure is reached. The material will go into the abrasive.

How do Abrasive tools work?

Abrasive tools are usually made of steel. And are divided into two pieces. One part is mounted on the fixed mounting plate. And the other is mounted on the mobile mounting plate.

Once the two metal plates combine together. A space appears inside, called the cavity. The material now enters the cavity of the injection unit through the nozzle of the mounting plate.

After pressing the screw, custom plastic parts manufacturers fill the cavity. The injection speed here is very important. And finally, the stroke has no cavity.

Once the sealing point reaches, the clamp element closes the material flow opening. And the material begins to cool in the abrasive tool. Then, open the grinding tool and take out the complete engineering plastic parts.

How do custom plastic parts manufacturers measure plastic molding parts?

The production size of the product determine injection molding machine large size. Similarly, the injection molding machine must carry the particulates. And the equipment also needs to suck the material from the large storage tank.

Generally, plastic is the closest material to our daily lives. Furthermore, it has wide range of applications. From everyday consumer goods to cutting-edge technology, is second to none.

So why is this material so essential to our civilization and culture? One is the uniqueness of the material.

- Strong against water and chemicals,

- light and durable.

- Inexpensive

custom plastic parts manufacturers can control its properties. However, these good materials alone

may not have made plastic so important to us.

In recent years, as the plastic industry has become more popular. The demand for custom plastic parts manufacturers has also increased.

According to statistics, the domestic plastic mold industry has accounted for 30% of the entire mold industry. And is still in a state of continuous expansion.

What does Insider say about Chinese custom plastic parts manufacturers?

In this regard, insiders pointed out that the “blowout” status of the domestic plastic mold industry. It has benefited from the continued improvement of the macro economy. Especially the rapid development of the:

- domestic automobile

- home appliances

- electronic communications and

- other industries.

The data shows that at present, the automotive industry alone needs 360,000 tons of various plastic products. And the demand for plastic products in other industries is increasing.

This shows that the strong demand for various types of plastic products. Undoubtedly laid the foundation for the development of the custom plastic parts manufacturers industry. Which in turn directly promoted the development of the industry.

Future of custom plastic parts manufacturers industry in China

However, it is regrettable that although the plastic mold industry has strong demand. Due to the serious shortage of domestic production capacity. Subsequently, most of the demand has to rely on imports.

The current status of the industry development is not satisfactory. The data shows that the current domestic production capacity can barely meet 50% of the market demand.

The huge capacity gap not only seriously affects the healthy development of the industry itself. But also drags down the development speed of related industries.

Therefore, vigorously developing the plastic mold industry is undoubtedly a top priority. And the key to cracking the demand gap. In fact, both the government and custom plastic parts manufacturers have fully recognized the importance of this issue.

The current situation of production capacity gap has also been alleviated to a certain extent.