항공 우주 및 방위

항공 우주 장비 제조와 관련하여 항공 우주 산업에서 사용되는 모든 부품의 생산은 최고 품질의 제품과 엄격한 표준 준수를 요구합니다. Kaito Mold Works, Inc.에서는 30 년 이상 복잡한 맞춤형 장비를 생산해 왔습니다. 수십 년간의 경험을 통해 항공기 및 우주선 용 기계 부품을 성공적으로 생산하려면 어떤 유형의 엄격한 표준을 충족해야하는지 알고 있습니다.

In addition, we understand the tight turnaround times and budget pressures aerospace organizations deal with. That’s why numerous organizations trust us to not just get it right, but to get it right on time and within budget.

MANUFACTURING STANDARDS FOR THE AEROSPACE INDUSTRY

Aerospace standards cover a host of processes, from material handling to manufacturing procedures. This is understandable, considering that equipment costs, performance expectations and safety concerns are all factors that contribute to some of the strictest technical and product regulations of any industry today.

To meet these standards with confidence, Kaito Mould Works has put into place a certified quality management system in accordance with AS9100D and ISO 9001:2015. Moreover, our accreditation is in accordance with the International Aerospace Quality Group Industry Controlled Other Party Management System. This means that all of our manufacturing, assembly, repair and engineering support of mechanical and electromechanical products follows the highest quality and industry standards.

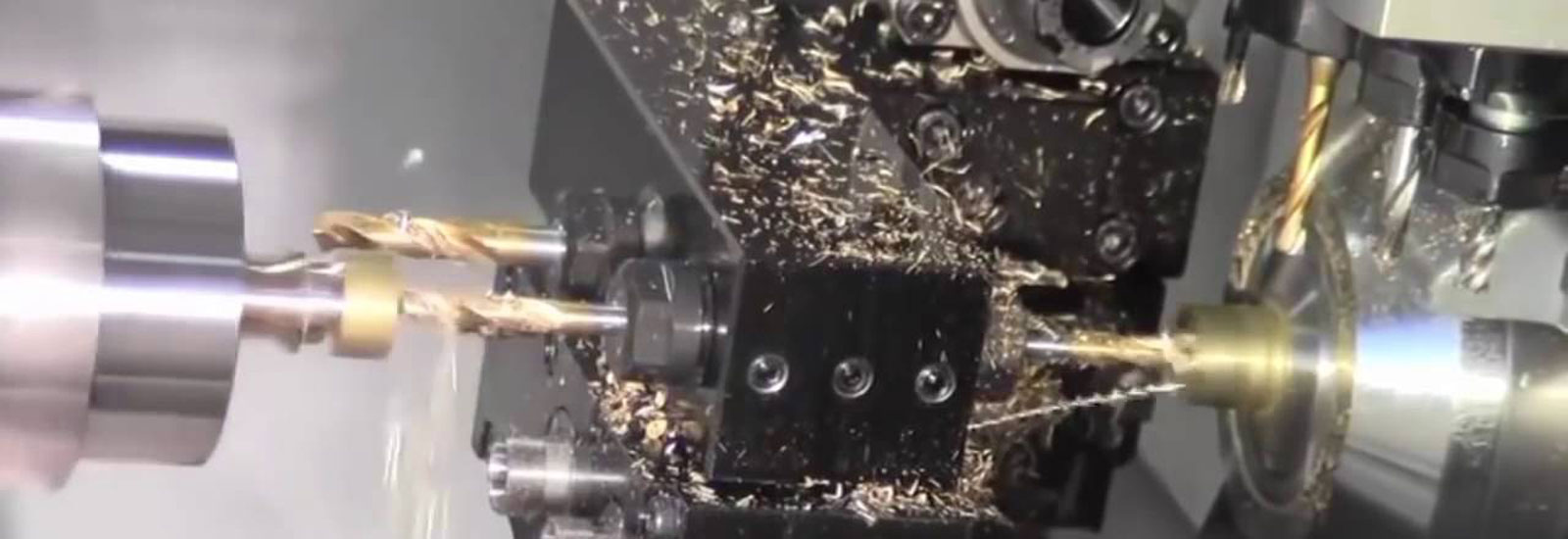

CNC Machining for Aerospace Parts

When lives and performance are on the line, every part and piece of equipment must be manufactured appropriately. The manufacturing process should also be repeatable whenever necessary. For this reason, we continually offer computer numeric control (CNC) machining to the aerospace industry. Ever since the late 1960s, this automated process has been used in the precision machining of high-performance parts and equipment. And at Kaito Mould Works, we’ve been honing our use of CNC aerospace machining for well over three decades.

In addition to the most respected CNC lathe machining in the industry, our highly experienced machinists, engineers and project managers also provide electrical discharge machining (EDM), 5-axis machining and milling, and panel wiring and control systems — to name a few of our many services.

Complex Orders Filled Effortlessly

Our ability to custom machine almost any aerospace part or piece of equipment is matched only by our experience in working with traditional and non-traditional materials. From aluminum and titanium to heat-resistant plastics and exotic alloys, we can make the part you need with full confidence.

In addition to filling the most complex orders, at Kaito Mould Works, we deliver value and know-how every day. You can rest assured that you’re employing a certified ISO 9001 and AS9100 small business with experienced customer service representatives who are all dedicated to your satisfaction.

We encourage you to conta us and learn more about our world-class facility in Ephrata, PA, which was specifically constructed for the streamlined manufacturing of high-quality parts and equipment.

Remember: When you have the need for affordable, dependable and efficient machining services, you need Kaito Mould Works on board.