What is aluminum die casting: (casting methods step by step explained?)

What is an aluminum die casting: (casting methods step by step explained?)

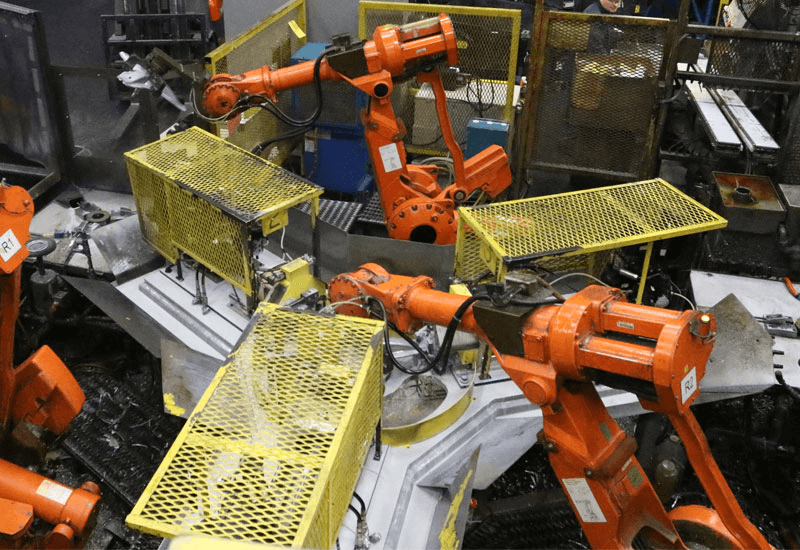

Die casting has actually become a very popular manufacturing technique in order to cast the metal products. Manufacturers repeatedly use aluminum Die Casting to produce several different sizes, thickness and shapes of die cast aluminum.

Moreover, they can produce different variety of shapes by using this process with perfect accuracy and fascination. Nowadays the process of Die Casting is rapidly using. It has several types according to the variations in the designing process which has used in specific conditions.

How does die casting process work?

Furthermore, this casting process is a best choice for bulk production. It can easily produce your metal parts in mass production with great speed. And these metal parts require less machining in post-production.

It has the following qualities like,

- highly conductive

- has ability to rapid production

- corrosion resistant

- consists of a good strength-to-weight ratio and stiffness

- it permits a great volume of die casting parts to produce rapidly.

Furthermore, it is very low-cost casting process in comparison to alternative processes. In this process, manufacturers melt the metals and then they produce the desire shapes of these metals.

Furthermore, today Aluminum Die Casting has become one the most economical and rapid forming processes. Because it is highly useful for creating components having uniform quality for a mass production.

It has the ability to produce hundreds of thousands of castings very quickly by using only one mold. In fact, it is very cost effective and its per unit cost is very low. It has now become the essential part of all the industries. Because it produces aluminum components not only for machines but also for sale or many other industrial and commercial production.

Other kinds of metals which Aluminum Die Casting involve

As we know that in Aluminum Die Casting, aluminum is the most important and basic metal. But it also involves many other non-ferrous metals. For example, in the die casting manufactures use 80% of aluminum with the combination of other alloys.

Moreover, there are many other alloys which they use in die casting. These are:

- Copper

- Magnesium

- Zinc

- Tin

- Lead

Additionally, all of these alloys have several different properties. And here are their melting points.

Alloys with high melting points are:

- aluminum 600°C

- magnesium 520°C

Alloys with low melting points are:

- zinc 380°C

- lead 320°C.

Which are 6 types of aluminum Die Casting processes?

There are actually 6 types of Aluminum Die Casting processes which will immensely help in your mass production. In fact, all types of die casting processes have designed and variated with some specific goals according to needs. In fact, all types of die casting processes have designed and variated with some specific goals according to needs.

Furthermore, they all have the same goal to cast a mold by using the same injected molten metal. But by depending on the kind of,

- melted metal

- part size

- and part geometry

different processes have ability to deliver you supreme results in comparison to alternate methods. As we have already described that there are two basic kinds of Aluminum Die Casting process. These are;

- Cold chamber

- Hot chamber.

1. Hot Chamber Aluminum Die Casing:

This technique has several different names like, hot casting and gooseneck casting. Basically, this technique of die casting is most popular in comparison to cold and other die casting. This process comes with a cylinder chamber.

In addition, this cylinder chamber of the injection mechanism totally immerses in the bath of molten metal. A feed system of gooseneck metal then draws the liquid metal inside the die cavity. Moreover, Aluminum Die Casting contributes much higher yields the cold chamber process.

This process provides extra comfortable and fast mold injection in the molten bath. And hence it also provides greater corrosion sensitivity. So, this die casting technique is a perfect solution for those applications which makes use of metals of high fluidity and low melting points.

Suitable alloys or metals for hot casting process are

- magnesium

- copper

- lead

- Cold Chamber Die Casting:

In the injection system, the molten metal is hand-ladled or automatically. Hence, it totally eliminates the urgency of the injection mechanism to immerse into the melted metal.

So, for the immersion design of hot Aluminum Die Casting, the applications which are so corrosive, cold die casting will be an ideal alternate. Furthermore, all these applications involve those casting of metals which have high melting temperatures.

Suitable alloys or metals for hot casting process are

- Aluminum

- Aluminum alloys.

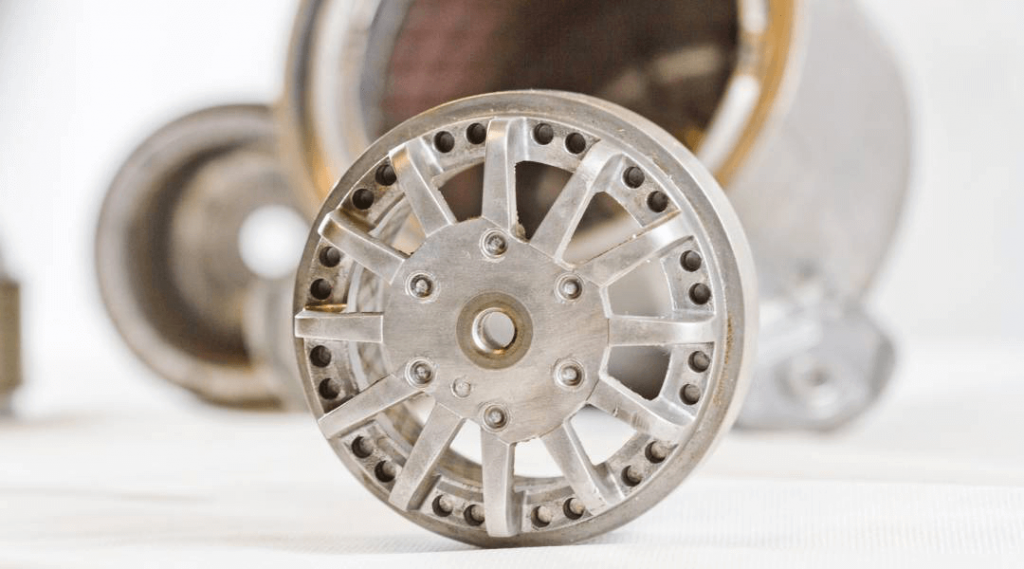

3. Low Pressure Aluminum Die Casting

Basically, this process of die casting is an ideal selection for those aluminum parts which are balance on all side of rotation of an axis. Moreover, vehicle wheels are the best example of it. Manufacturers often fabricate them by using low-pressure die casting.

This technique of Aluminum Die Casting, the mold locates vertically on the top of the bath of melted metal and it is connected through a riser tube. When manufacturers pressurize the chamber, it pulls the metal upward and into the mold. The temperature of pressurizing generally lies between 20 and 100kPa.

- Squeeze Die Casting

Basically, manufacturers had created this die casting process to find a workable solution to cast alloys and metals having low fluidity. This die casting process actually provides the products that are highly dense.

Moreover, it is a complementary technique of die casting which subsequent the heat-treating. Manufacturers often associate this process with melted aluminum. Additionally, they use this process for those applications which call for fiber strengthening.

- Vacuum Die Casting

Manufacturers generally use this aluminum Die Casting process for those applications which have post casting heat treatment. There are two benefits of this process like,

- it reduces turbulence

- limits gas inclusions.

This technique makes sure low porosity to the material and also enhanced strength.

- Semi Solid Die Casting

This die casting process actually provides maximum density and minimum porosity inside the casted material. it is also famous for another name like, Thixo-forming. Moreover, it provides an added benefit of best precision.

Suitable alloys or metals for hot casting process are

- Aluminum alloys

Conclusion:

Hence, aluminum Die Casting process has ability to produce highly accurate components with perfection and perfect choice for bulk production. It also creates high-volume metal components for you mass production. Nowadays all manufacturing industries are relying on these die casting processes that we have described above.

Moreover, industries like, aerospace, auto and power tools are making use of these latest techniques to produce highly precision components. They are trusting these processes of die casting because they are,

- Highly reliable

- Provide high quality

- Rapid production for bulk production

- Minimal assembly

- Versatility in designs.