Diferenca midis makinerisë CNC dhe printimit 3D

Ndërsa teknologjia përparon dhe revolucionarizon inxhinierinë dhe makinerinë, ju doni të dini se jeni duke përdorur pajisjet më të mira dhe po drejtoni biznesin tuaj përpara. Disa nga këto përparime janë në përpunimin e kontrollit numerik kompjuterik (CNC) dhe shtypjen 3D. Të dy punojnë me materiale të ndryshme. Por cila është më e mira për nevojat tuaja?

Përpunimi CNC dhe shtypja 3D kanë ngjashmëri dhe ndryshime, dhe secili ka përfitime unike. Ato kanë rrethana të ndryshme kur dëshironi t'i përdorni në lidhje me koston dhe disponueshmërinë. Prishja e secilit stil prodhimi do t'ju ndihmojë të zgjidhni metodën më të mirë për ju dhe biznesin tuaj.

Dallimet kryesore të tyre ndodhin në prodhim , mbetje , shkallë , disponueshmëri të materialit dhe madhësinë e pjesëve.

NGJASHMSIT B NDRMJET CNC DHE PRODHIMTARIT SHTES (PRINTIMI 3D)

Përpunimi CNC dhe prodhimi shtesë janë të dyja zgjidhje të kontrolluara nga kompjuteri për të bërë produkte nga një material i caktuar. Ata janë të dy makinat në ballë të teknologjisë së ndërtimit në mënyrë të sigurt dhe efikase.

As machinists and engineers want to build a prototype, a part or a custom product, they can turn to one of these machines to do the job for them. As long as the machines have the design, you don’t have to worry about human error because the machines are automated. While this doesn’t mean issues don’t arise, there’s more consistency with production and less chance of injury.

There is some overlap with these two manufacturing methods. Some CNC machines can use STL and OBJ files, which 3D printers also accept.

CNC machinery is older than 3D printing and still has a stronger foothold in manufacturing. The form started in the 1940s and had molded to fit into the industry up to the present. 3D printing came along in 1986. It’s still relatively new and evolving to be more accessible and versatile. 3D printing can help in some areas of prototyping, but it’s not a replacement tool for CNC machining.

They’re not so much alternatives to the other as they are both aspects of the manufacturing world. They meet different demands and handle different materials and markets. CNC machines and 3D printing both have unique capabilities and constraints that suit them for specific jobs. As they fit their niches in the market, you’ll want to compare it to whatever industry you’re in.

DIFFERENCES BETWEEN CNC MACHINING AND 3D PRINTING

Prej metodave të tyre të ndërtimit e deri te ato aplikacione që mund të trajtojnë, përpunimi CNC dhe shtypja 3D ofrojnë zgjidhje kreative në mënyra jashtëzakonisht të ndryshme. Gjetja e ndryshimeve dhe pikave të tyre të forta do t'ju ndihmojë të gjeni se cila është e përshtatshme për ju dhe biznesin tuaj.

Printerët 3D janë zakonisht më efikasë sesa prodhimi tradicional. Printeri përdor materialet që përbëjnë artikullin që po krijon, ndërsa metodat tradicionale të prodhimit të tilla si Machining CNC kërkojnë më shumë materiale që myku të funksionojë. Mesatarisht, printerët 3D prodhojnë më pak mbeturina sesa metodat tradicionale të prodhimit.

However, when production is large-scale, traditional manufacturing methods have a distinct advantage. Assembly lines are faster than a 3D printer in mass production because printers build layer by layer. In the hours that it could take to 3D print a product, an assembly line could have mass-produced hundreds of the same product.

Additionally, 3D printers can only use the area of the printing bed for making parts. Large-scale parts might not fit in that space. While the parts can be broken down into smaller pieces 3D printers can build, that might not be cost-effective and will take time. Traditional manufacturing has the advantage of the assembly line’s labor and will be able to produce items on a larger scale. Future 3D printers could be able to build larger items, but not on the level of what CNC machines offer with regard to quality and quantity.

3D printers can manipulate different materials such as plastics, metals and polymers. However:

- Not all 3D printers can use these materials. It takes separate machines for each material.

- 3D printers cannot work with every material that traditional manufacturers use due to high melting points.

- Some projects might not be able to consider using 3D printers if they require specific materials that are incompatible with the printers.

Here is the bottom line — 3D printing won’t replace traditional manufacturing because of its disadvantages in mass-produced items.

3D Printing vs. Traditional Manufacturing

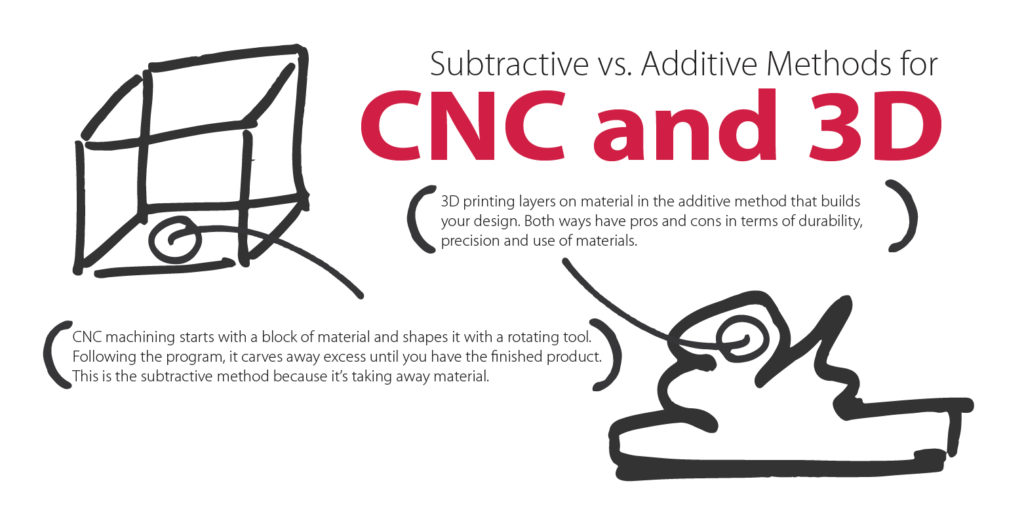

CNC machining starts with a block of material and shapes it with a rotating tool. Following the program, it carves away excess until you have the finished product. This is the subtractive method because it’s taking away material.

3D printing layers on material in the additive method that builds your design. Both ways have pros and cons in terms of durability, precision and use of materials.

Material Usage for CNC and 3D

CNC machining works with a variety of materials. They can use:

- Metal alloys

- Woods

- Acrylic

- Modeling foam

- Thermoplastics

- Machining wax

CNC machines have heating systems that can manage heavy materials. These materials are used to build substantial parts for engines, aircraft and other machines. They need to be exact, dependable and durable. The cutting tools for the design might have to switch, but most tools are standardized to fit any CNC machine.

3D printing doesn’t have this variety, using materials like plastics or resins. They can’t produce items strong enough to withstand intense environments like airplanes or other machinery. Also, 3D printers can’t switch between materials. Certain 3D printers are for specific kinds of material.

3D and CNC Precision of Production

CNC machining is more precise and consistent than 3D printing because they have a higher tolerance for heat. 3D printers end up with distorted products when there’s too much heat. They can offer precision but cannot remain consistent. 3D printers are often regarded as more user-friendly than CNC machines, but when they malfunction, someone has to troubleshoot them because the fault means production of unusable products.

CNC and 3D Speed of Production

CNC is a faster solution than 3D printing. Automated CNC machines can work around the clock as long as they’re properly maintained. A project that could take CNC machining an hour would equate to a 3D printer taking hours to get the final product because it has to build the product layer by layer. A 3D printer’s pace might have to slow down during the process to get the design right. Different 3D printers could also be programmed with specific speeds that you can’t alter. It depends on the machine you use.

Produktet e shtypura 3D gjithashtu kërkojnë punë pasi të jenë ndërtuar. Produktet duhet të lahen, të lustrohen dhe të mbyllen para se njerëzit të përdorin produktin. Kjo mund të zgjasë testimin e prototipit në një periudhë më të gjatë kohore me shumë pritje në mes. Printerët 3D janë gjithashtu të njohur për artikujt më të vegjël, të prodhuar me porosi. Por nëse duhet të prisni që artikulli të ndërtohet dhe të bëni ende shumë punë pas printimit, ju humbni shumë kohë para se të mund ta zhvendosni produktin.

Shkathtësia e Makinerisë për CNC vs 3D

Makineritë CNC mund të prodhojnë pajisje, mjete dhe pjesë të dizajnuara me porosi. Ata kanë një gamë të gjerë cilësimesh të cilësisë, kështu që ju mund të bëni një prototip që ka një dizajn më të ashpër në disa zona dhe të përsosur në të tjerët, në mënyrë që të mund të provoni atë pjesë.

Kur teston prototipat për një projekt, një makinë CNC mund të ndërtojë shpejt një dizajn në mënyrë që zhvilluesit ta testojnë atë. Printerët 3D nuk kanë këto lloje opsionesh. Ai do të formojë ngadalë modelin ashtu siç ishte programuar. Saktësia është thelbësore kur ndërtohet një produkt përfundimtar, por kur koha është një pengesë dhe ju doni të provoni disa prototipa, printerët 3D mund të ngadalësojnë ju dhe projektin tuaj. Projektimet e bëra për një makinë CNC zakonisht nuk mund të zëvendësohen me një printer 3D sepse produktet janë voluminoze dhe do të duheshin orë që një printer 3D t'i përfundonte ato.

Zhurma dhe rrëmuja Prodhuar nga CNC dhe 3D

These differences relate to the subtractive and additive methods. CNC machining is much more noisy and messy than 3D printing because it uses a tool to cut away material. This creates noise and a lot of scrap metal or wood shavings. CNC machines cause a lot of vibrations, so they need to be in a space where they won’t bother anyone. 3D printing only uses the material it needs for the product. There’s little to no waste, and the printers don’t vibrate like a CNC machine.

Applications for CNC and 3D

CNC machining can manufacture bigger products and can handle heat-resistance. 3D printing has more niche categories, such as printing food or working in space.

CNC Machining vs. 3D Printing

Sipas World Finance, shtypja 3D nuk është një zgjidhje që mund të zëvendësojë përpunimin CNC. Printimi 3D është një pjesë e botës së prodhimit, por nuk është shpikja ajo që do të ndryshojë tregun siç e dinë të gjithë.

Printerët 3D mund të përmirësojnë aspekte të caktuara të prodhimit por nuk mund të trajtojnë të gjithë tregun, pasi përpunimi CNC funksionon akoma më mirë në shumë situata. Përpunimi CNC ende ofron cilësi më të mirë se printerët e shtrenjtë 3D.

Në një shkallë më të vogël prodhimi, printerët 3D kanë avantazh në kursimin e parave të bizneseve nga blerja e formave të shtrenjta. Ato gjithashtu ofrojnë një pasqyrë të formës dhe estetikës së produktit. Por ndërsa prodhimi rritet dhe faktorët e kohës, ato nuk qëndrojnë aq mirë sa makinat CNC.

P BRFITIMET E MAKINIMIT CNC MBI PRINTIMIN 3D

CNC machining fits with mass production. It can create many products in a shorter period, where 3D printing would take hours to create one product. That’s just one advantage of CNC. Let’s take a look at some others.

Prototyping Becomes Easier

CNC machines are better for prototypes that can withstand structural tests because they carve the design from the material. They can also build prototypes out of the exact material that will be used to make the final product.

Structural tests and alterations will be more accurate because they use the same material. This could speed up the production process because the changes will be to the design and not the material. 3D printers don’t fabricate prototypes with the structural strength, so they can’t conduct physical tests.

Prototype Integrity Improves

CNC machines don’t heat the material and reform it. The material stays stronger and has a better structural integrity than 3D printers, which have to heat the material to build the intended product. 3D printers might also have to add foreign materials to the mixture to be able to make the prototype, which CNC machines don’t need.

Surface Finish Advantage

CNC machines provide better surface finish than 3D printing because the materials don’t deform during the process. The rigid material and cutting action keeps the product together and has fewer chances for mistakes or deformations to occur. 3D printing has poorer surface finish. The material bends, warps or distorts because the material is layered heated plastic.

Tolerance Levels Rise

CNC machines work with higher precision, so the parts have a better tolerance than 3D printers. Because of tolerance level, prototypes that have shafts or connect to other parts will be higher quality and will more likely fit with other components.

Price and Volume Don’t Dictate Price

3D printing costs depend on the volume of needed materials. Final product volume doesn’t dictate the price for CNC machines. 3D printing wouldn’t be cost-effective with larger orders, and this is the situation where CNC machines thrive.

Quality in Favor of CNC

Larger layers from a 3D printer are faster but not as high-quality as smaller layers. If you need a prototype, you have a choice to get it fast but of slightly less quality, or wait longer for the prototype with the best quality the printer can provide. CNC machines have the option for you to choose resolutions for your item. They can offer varying qualities in a short amount of time, making them ideal for quick builds and immediate results for testing.

Keeping Costs Down

If you have the option of choosing which manufacturing method to use for your product, CNC machining is usually cheaper than 3D printing.

Contact Kaito mould Works, Inc., for Your CNC Machining Needs

CNC machining can build the parts you need for your business. Our expert machinists at Kaito Mould Works, Inc., will provide outstanding work that will help you reach your goals. We aim to help you get the correct part for your project.

Kaito Mould Works, Inc., provides services for custom machine building, precision parts machine and reverse engineering of components to give you the product you need promptly. We deliver exceptional CNC machining solutions for manufacturers in multiple industries. Our skill in specialization and dedication to our work will help you and your business stay on the cutting edge of the industry. We have the solutions you need. Get in touch with us today.

Nëse mund t'ju ndihmojmë me projektin tuaj, ju lutemi na telefononi në 0086-769-82821468 ose dërgoni email sales@kaitomould.com.