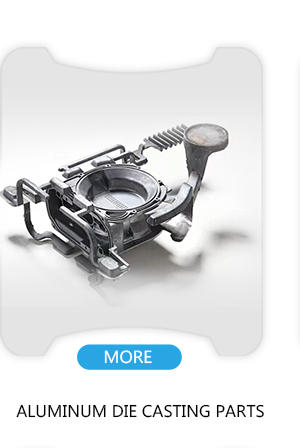

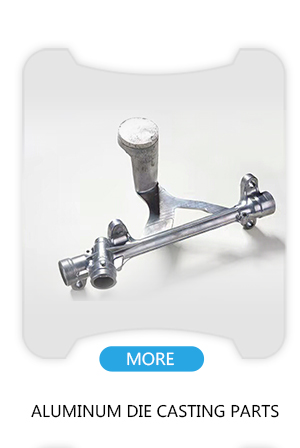

ダイカスト金型

Kaitoは、10年以上にわたり、アルミニウム、亜鉛、およびマグネシウム部品のISO認定の費用効果の高いダイカストメーカーです。

私たちのダイカスト工場は優れた機械加工と品質チェック装置を持っていませんが、10年以上の経験もあり、熟練したダイカストエンジニアリングチームと技術者チームがアルミニウムダイカストの設計、開発、製造、製造、後処理から完全なソリューションを提供します部品、亜鉛ダイカスト部品、マグネシウムダイカスト部品。 Kaitoは、今日の厳しい製造環境向けに、プロトタイピング、少量生産、および生産ダイカスト金型を製造しています。

Kaito Main service for Die casting project:

Production Die casting mold:

Hard tool or H-13 serial steel for die-cast mold is an excellent process for higher quantity requirements. It is a larger upfront mold cost investment, but a significant reduction in re-occurring costs. Production die-cast parts have highly repeatable properties and tolerances.

Typical Lead Time:

- Tooling = 4-8 weeks (depends on part size and structure)

- Samples = 1-2 weeks

- Production (Qty 10k) = 3-4 weeks

Tooling Life Expectancy:

- 300k shot

Prototype mold for die casting:

The term “Soft mold” is used to describe a die-cast mold made out of cheap and soft steel. The running faster feed rates when CNC Machining and simples the mold structure to save mold cost. Typically the mold life and reach 10, 000 to 30, 000 parts before showing any significant wear.

Typical Lead Time:

- Tooling = 2-5 weeks (depends on part size and structure)

- Samples = 1-2 weeks

- Production (Qty 100) = 3-5 days

Tooling Life Expectancy:

- 10k shots

Post Machining

Kaito provides CNC machining including milling, drilling, tapping, countersinking, boring and reaming for the machining of die casting parts

Surface Finishes

Not our wide assortment of vibratory deburring and shot blasting equipment, but also we have established relationships with well-qualified suppliers for powder coating, electrostatic painting, anodizing, zinc, copper & nickel plating, and heat treat/stress relieving.

Die Casting Alloys

Not only can die-cast alloys withstand high operating temperatures, but they are also fully recyclable. We routinely pour a broad range of non-ferrous materials. The following are some of the most common alloys being used:

- Aluminum dies casting alloys: A380, AL383 A360, A356, and so on.

- Magnesium dies casting alloys include AZ91D and AM60B.

- Zinc die casting alloys to include ZA3, ZA12, and ZA27, Zamak #3, ZA-8

What kind of component you can consider to choosing for die casting?

- What kind of component you can consider to choosing for die casting?

- The part not only needs high process stability but also high dimensional accuracy.

- The part needs good strength value.

- The part needs good strength value.

- The part needs shorten casting cycle time for high profitability.

- The part needs the specified parameter for the reproducible quality of the components.

How Katio works as your reliable custom die casting mold manufacturing and production manufacturer?

On customer R&D stage :

- Provide die casting considerations and options consistent with customer demands to reduce the risk of defective parts through our customer early design stage.

- Prior to the die casting mold build stage, kaito can provide support for the rapid prototyping of aluminum.

- And the zinc part.

- Budget and value-engineering die casting project with costing and effective manufacturing process.

- Help your project with lower cost but high profitability.

Die casting mold design and manufacturing stage:

- Advanced CAE Softwares ensure accuracy for your part design, mold design, and manufacturing.

- For critical quality requirements, we use advanced computer simulation software to do mold flow analysis to avoid casting problems by predicting the metal flow, filling characteristics, and solidification of the material.

- It allows design improvements to be incorporated during the build process, avoids the expense and time lost in changes made after the mold is completed.

- Professional project team monitor dies casting mold processing and sampling through continual communication with certified suppliers and customer weekly actual schedule with pictures update to the customer.

Tips for Design Die-casting Part:

- As cast tolerance as tight as +/- .005″, post-machining available for tighter tolerance applications.

- Standard tolerance of +/- .010″ for the first inch and +/-.002″ each additional inch.

- The typical surface finish of Ra 63-125 micro-inch as cast, post-machining suitable for higher quality surface finishes.

- Min. draft angle = .5 degrees.

- Min. wall thickness = .030″ (Thinner wall thickness possible with alternative processes).

私たちはあなたのプロジェクトのお手伝いをすることができた場合は、下記にご連絡ください0086-769-82821468または電子メールsales@kaitomould.com