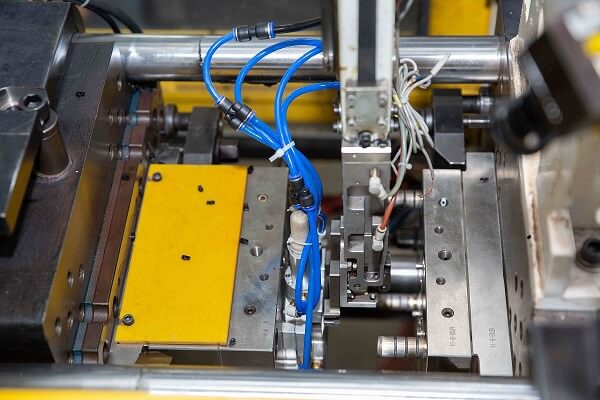

플라스틱 금형에 대한 10 가지 금형 제조업체 팁 (2020 년 9 월)

어떻게 금형 제조 업체 품질 석고 금형을?

Are you interested in learning the basics of 금형 제조 업체싶으십니까? 도자기, 석기 또는 토기 요리를 만들기 위해 작업장에서 석고 주조를 이미 시작 했습니까? 아니면 좀 더 조각적인 프로젝트를 개발하고 있습니까?

Have you encountered any difficulties with the use of your plaster or the resistance of your molds? If there is one element that should not be overlooked in appreciating the casting process, it is the quality of the plaster.

Practical steps for a successful mold

To obtain a good mold, like 금형 제조 업체, it is necessary to anticipate the stages of its project. We will review together the preparatory phases for the manufacture of a plaster mold. The right questions to ask before production and how to choose a quality plaster.

The steps to make a piece of porcelain

First of all, the first thing to do when you want to make a ceramic part is to create your model.

Using a drawing representing the part at the desired size. The modeler must anticipate the shrinkage that the part will undergo during firing. For this, the modeler will create his mold with a volume of plaster larger than the actual size of the part. It is estimated at + 14%.

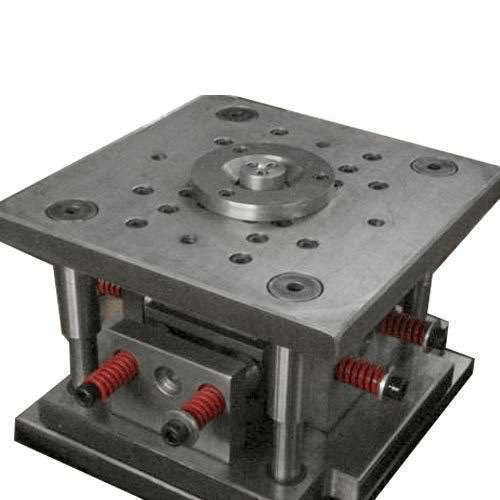

This created model is called the mother 금형 제조 업체. It will be used to make production molds called matrices.

The dies are the molds that will make it possible to make ceramic parts, especially porcelain. They will therefore be used directly for our production.

As you can see, these two types of molds do not have the same utility, and it is very important to differentiate them.

Questions to ask 금형 제조 업체 before starting production

Before starting a production, it is imperative to ask the following questions:

- I want to make a “mother mold” or a die?

- What object do I want to obtain in molding?

- A cafeteria?

- A vase?

- A cup?

- A plate?

At this point a professional 금형 제조 업체 advises you to study the shape well. You can even make a small cardboard model to help you visualize the object in 3D.

Be careful not to hamper your creativity by wanting to “fit into the mold”. With time and practice you will intuitively know which shape is interesting to produce in molding.

What process will be suitable for my molding?

The casting? calibration? isostatic pressing? The modeling?

Find out about the most used molding processes in the article clay molding for beginners which describes the steps step by step.

What type of plaster will be suitable for my mold project?

Each plaster needed to make a mold has its own specific characteristics. This is why the choice of the plaster to be cast is a fundamental step before embarking on the manufacture of any ceramic part.

Choose a quality plaster 금형 제조 업체

There are many plasters 금형 제조 업체 but some are suitable for ceramics. So, don’t go looking for a random cast at the local DIY store.

You should know that plaster is initially a very volatile powder composed of gypsum. Its manufacturing process makes it permanently porous. When it is mixed with water, a chemical reaction is created.

It causes it to harden, this is called “plaster setting”. This preparation can be facilitated if one is familiar with the procedures to follow, but also according to the quality of the plaster.

Versatility of mold

In ceramic, we choose to use plaster because it is a very versatile material, as it is tender, it can be sculpted at will. One can obtain surfaces while texture or conversely t smooth almost, complex or otherwise of great simplicity. We therefore need a m flexible job material for creating different types of art pieces.

The precision of the mold

It is also interesting for 금형 제조 업체 to work the finish molds by hand with precision. A quality plaster has a fine grain with few impurities. It must ensure a perfect reproduction of details. It must be pleasant to work with, whether you dig it, smooth it, sand it, etc.

Durability

We also want our mold to be sustainable. That we can handle it for several years without it getting damaged too quickly. Because making molds can take a long time, and requires great care. We don’t want to start over every 6 months!

However, plaster remains a friable material. That is why a great resistance and toughness is desired as well as stability in the product quality.

10 tips for perfect 금형 제조 업체

- Ensure optimal working environment conditions: T ° of 22 ° C and relative humidity less than 60%.

- Make a perfect model or matrix effectively sealed to avoid any porosity. If necessary, apply a sealant.

- Use a high-quality release agent that is perfectly compatible with the resin used.

- Choose an appropriate rigid or elastomeric molding system based on the part to be cast. Evaluate your need for a release agent and select it according to the part.

- A 금형 제조 업체should thoroughly disperse the materials of each container separately.

- Observe precisely the mixing ratio of parts A and B by weight or volume as indicated in your supplier’s technical sheet.

- Make a perfectly homogeneous mixture of parts A and B. Polymerization can only be carried out completely after having carefully and long insisted

- Perform a fine casting at a strategic point according to the design of the part.

- Wait for complete polymerization of the mold on the model before starting the demoulding.

10.Do not neglect the regular maintenance of the mold in order to avoid a build-up of release agent.

If you don’t know

Do you have any doubts or do you think you have followed all these steps, but your mold does not meet your expectations? Kaitomould certainly have the answer.

Conclusion

I hope that these criteria will allow you to perform casts that meet your expectations. Of course, the practice of molding cannot be improvised with a 금형 제조 업체. The process includes steps to be observed. But a single mold, even very simple, can already bring a lot of interest to your production! So, don’t hesitate to get started!